-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 07, 2024 05:42 Back to list

fencing mesh factory

The Rise of Fencing Mesh Factories An Overview

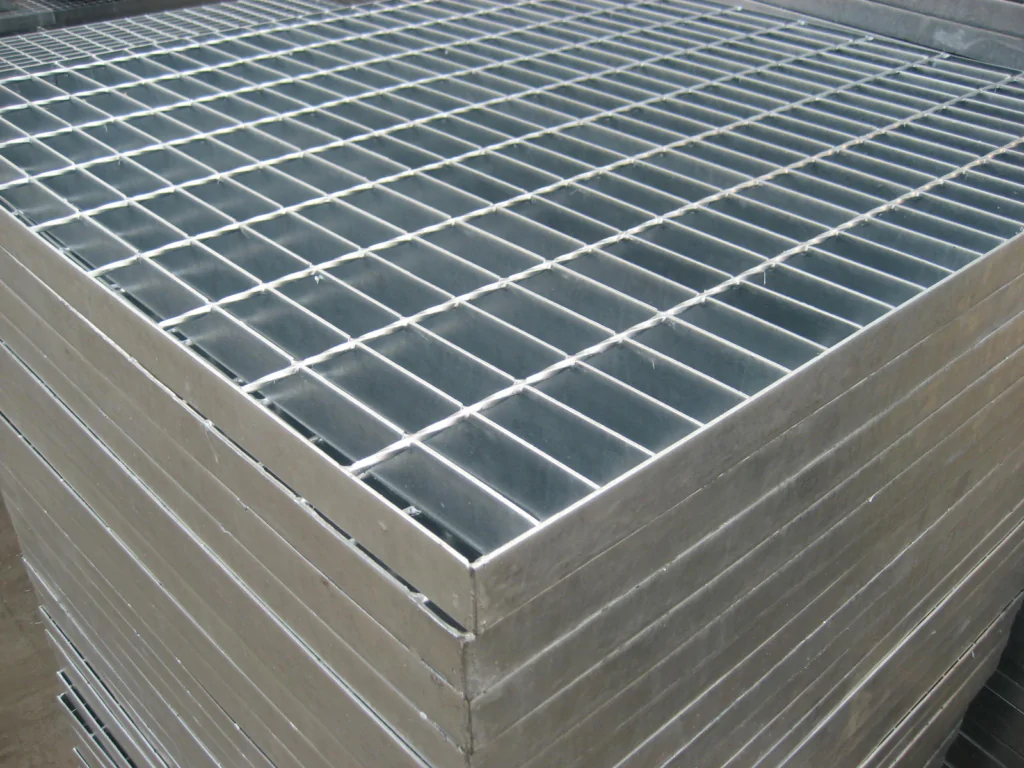

In recent years, the demand for fencing solutions has seen a remarkable increase across various sectors, from agriculture to urban development. At the heart of this growth lies the fencing mesh factory, a vital player in producing versatile fencing materials that cater to an array of needs. This article explores the significance of fencing mesh factories, the manufacturing process, and the diverse applications of their products.

Importance of Fencing Mesh

Fencing mesh is crucial for security and boundary demarcation. It serves a multitude of purposes, including safeguarding properties, protecting livestock, and delineating spaces for environmental preservation. Additionally, fencing mesh plays a significant role in construction, serving as a support system for various structures. With urbanization on the rise, the demand for reliable fencing solutions has never been greater.

The fencing mesh itself is typically made from materials such as steel, aluminum, or plastic. These materials must possess the right balance of durability, flexibility, and design. The robustness needed often leads to a preference for steel mesh, particularly in applications requiring higher security, while lighter materials might be utilized for agricultural fencing.

Manufacturing Process of Fencing Mesh

Fencing mesh factories employ advanced machinery and technology to produce high-quality mesh products that meet industry standards

. The manufacturing process generally involves several key stages1. Raw Material Selection The journey begins with the careful selection of raw materials. Quality steel or coated wire is chosen to ensure that the end product withstands environmental stresses and other mechanical forces.

2. Wire Drawing The raw metal is drawn through a series of dies to reduce its diameter to the desired gauge for fencing. This process enhances the tensile strength of the wire.

3. Weaving The drawn wire is then woven into a mesh configuration. This can be done using various techniques such as welded, woven, and chain link processes, each offering different benefits based on the intended application.

fencing mesh factory

4. Coating To protect the wire from corrosion and extend its lifespan, a coating—typically of zinc or plastic—is applied. This step is crucial, especially for fencing items meant for outdoor use, where exposure to moisture and other environmental factors can lead to rusting.

5. Cutting and Packaging Once the mesh is woven, it is cut to specified lengths, packaged, and prepared for shipping. Factories often have strict quality control measures in place to ensure that the products meet customer specifications and industry standards.

Applications of Fencing Mesh Products

The versatility of fencing mesh makes it suitable for a wide range of applications

- Agricultural Fencing Farmers utilize fencing mesh to protect crops and livestock from predators. It helps create safe enclosures, ensuring that animals are kept secure while also allowing for ventilation and visibility.

- Construction Sites Fencing mesh is used as a perimeter fence on construction sites, providing security and preventing unauthorized access. Additionally, it serves as a protective barrier to keep debris and materials contained.

- Urban Development As cities expand, fencing mesh helps define property lines and provide privacy for residential areas. In public spaces, it is also used to prevent trespassing in sensitive zones like parks and nature reserves.

- Industrial Applications Warehouses and factories utilize fencing mesh to secure their premises. Custom solutions are available for particular needs, such as high-security environments that require enhanced strength and resistance.

Conclusion

Fencing mesh factories play a pivotal role in meeting the growing demands for fencing solutions worldwide. Their ability to produce high-quality, durable, and versatile fencing products has made them indispensable across multiple sectors, ensuring safety, security, and functionality. As urbanization continues and the need for land demarcation and protection rises, the relevance of fencing mesh factories is set to increase, paving the way for further innovation in this essential industry. The future holds exciting possibilities for both manufacturers and consumers as the fencing solutions evolve to meet the changing landscape of our world.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025