-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 10, 2024 08:01 Back to list

Expert Manufacturers of Durable Galvanized Binding Wire for Versatile Applications

Understanding the Role of Galvanized Binding Wire Manufacturers in the Construction Industry

In the ever-evolving construction landscape, galvanized binding wire plays a significant role, acting as an essential material for various applications, including fencing, reinforcement, and binding. This versatile wire is crucial for ensuring structural integrity and durability in construction projects, and hence the role of galvanized binding wire manufacturers cannot be overstated.

What is Galvanized Binding Wire?

Galvanized binding wire is made from iron or steel that has been coated with a layer of zinc to increase its corrosion resistance. This process, known as galvanization, not only protects the metal from rust but also enhances its overall lifespan. The wire is typically available in various gauges and can come in soft and hard forms, making it suitable for different applications. Due to its strength and resistance to environmental factors, it finds extensive use in construction, agriculture, and various industrial applications.

Importance of Quality Manufacturing

The quality of galvanized binding wire is paramount. A reputable manufacturer employs stringent quality control measures during the production process. This includes using high-grade raw materials, advanced galvanization techniques, and thorough testing methods to ensure that the products meet international standards. High-quality binding wire guarantees superior performance, which is crucial when used in critical structural applications. Poor quality wire, on the other hand, can lead to failures and costly repairs, making the choice of manufacturer a vital consideration for contractors and project managers.

Innovative Manufacturing Techniques

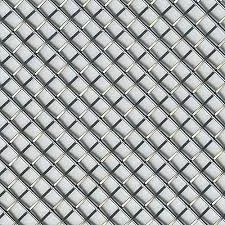

galvanized binding wire manufacturer

Modern manufacturers are increasingly leveraging advanced technologies and innovation to enhance the quality and efficiency of their production processes. Automated machines and equipment enable precise wire diameter and tension settings, ensuring uniformity in the finished product. Furthermore, some manufacturers are adopting eco-friendly practices to reduce their environmental footprint, utilizing sustainable materials, and implementing waste reduction strategies. These innovations not only lead to better products but also promote sustainability in the construction sector.

Custom Solutions for Diverse Needs

Every construction project has unique requirements, and a qualified galvanized binding wire manufacturer understands this need for customization. Leading manufacturers often provide tailored solutions, including bespoke wire lengths, gauges, and packaging options, catering to specific client needs. This flexibility is vital, particularly in large projects where the quantity and specific characteristics of materials can vary significantly.

Applications in Various Industries

Galvanized binding wire is utilized across a wide range of industries. In construction, it is commonly used for binding rebar, securing scaffolding, and fencing applications. In agriculture, it is essential for creating durable fencing solutions, supporting crops, and even in irrigation systems. In manufacturing, it can serve as a component in various products requiring binding or structure. The versatility of galvanized binding wire means that it is indispensable across numerous fields, underscoring the importance of choosing a reliable manufacturer who can deliver a product that meets the necessary specifications.

Conclusion

In conclusion, the role of galvanized binding wire manufacturers is crucial in the construction industry and beyond. Their commitment to quality, innovation, and customization enables contractors and builders to rely on these materials for their structural needs effectively. As the demand for high-quality construction materials continues to grow, the importance of selecting the right manufacturer becomes ever more critical. By understanding the nuances of galvanized binding wire and the manufacturing process, industry stakeholders can ensure the successful completion of their projects, bringing durability and safety to the built environment.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025