-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 12, 2024 12:41 Back to list

galvanized fence manufacturer

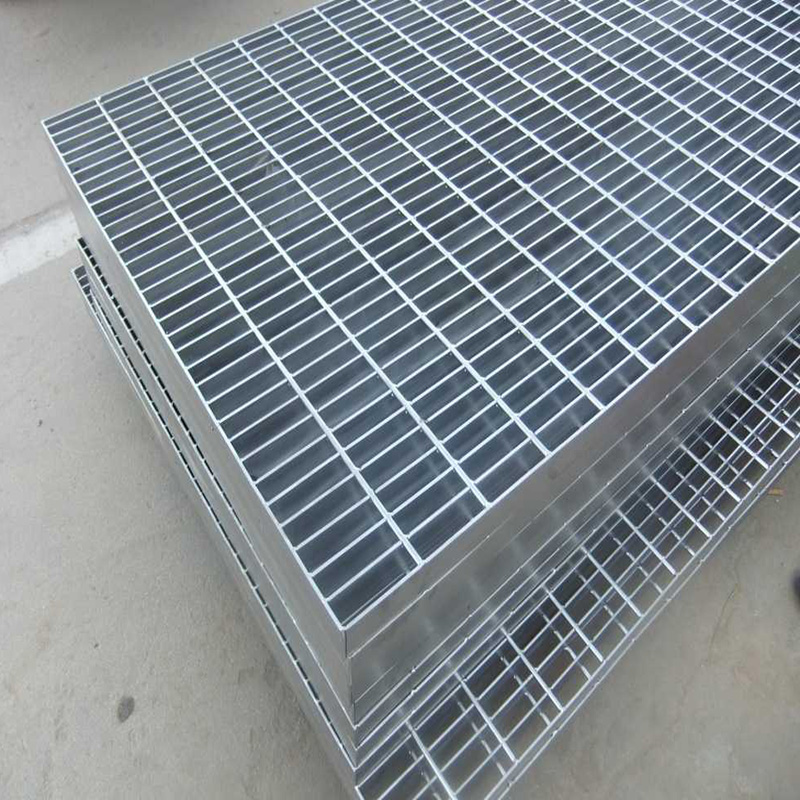

Understanding Galvanized Fence Manufacturing A Comprehensive Overview

In the world of fencing, galvanized fences hold a significant place due to their durability, aesthetic appeal, and cost-effectiveness. The production of galvanized fences involves a thorough understanding of materials, processes, and market demands. This article provides an insight into the galvanized fence manufacturing process, its advantages, and factors to consider when choosing a manufacturer.

What is Galvanization?

Galvanization is a process that involves applying a protective zinc coating to iron or steel in order to prevent rusting. This process enhances the longevity of the metal and is a crucial step in the production of galvanized fences. The most common methods of galvanization are hot-dip galvanization and electro-galvanization. Hot-dip galvanization, which is often preferred, involves immersing the steel in a bath of molten zinc, creating a robust and long-lasting protective layer.

The Manufacturing Process

The manufacturing of galvanized fences typically follows several key steps

1. Material Selection The primary material used for galvanized fencing is steel. Manufacturers choose high-quality steel to ensure strength and durability.

2. Fabrication Once the steel is sourced, it is cut and shaped according to the design specifications of the fence. This may involve welding, bending, or machining to create individual panels, posts, and fittings.

3. Cleaning Before galvanization, the steel components must be cleaned to remove any rust, oil, or dirt. This is critical as it ensures proper adhesion of the zinc during the galvanization process.

4. Galvanization The cleaned components are immersed in hot-dip zinc, which forms a metallurgical bond with the steel, thus providing a barrier against corrosive elements. The thickness of the zinc coating can be tailored to meet specific environmental conditions and customer requirements.

5. Cooling and Inspection After galvanization, the fences are allowed to cool naturally. Each piece is then inspected for coating uniformity, adherence, and any potential defects.

6. Packaging and Delivery Finally, the finished galvanized fence materials are packaged appropriately for shipment. Manufacturers often work with logistics partners to ensure timely and safe delivery to customers.

Advantages of Galvanized Fences

Galvanized fences offer several advantages, making them a popular choice for both residential and commercial properties

galvanized fence manufacturer

1. Corrosion Resistance The zinc coating effectively protects the steel from moisture and environmental elements, significantly extending its lifespan.

2. Low Maintenance Unlike traditional wooden fences, which may require frequent staining or painting, galvanized fences require minimal upkeep. Routine inspections and occasional cleaning are usually sufficient.

3. Cost-Effectiveness Although the initial investment in galvanized fencing may be higher than non-galvanized options, the long-term savings from reduced maintenance and replacement costs make them a smart financial choice.

4. Versatility Galvanized fences come in various styles, including chain-link, picket, and wrought iron, catering to diverse aesthetic preferences and functional needs.

5. Environmental Benefits Galvanization is an environmentally friendly process. Zinc is recyclable, and the longevity of galvanized fences reduces the need for frequent replacements, thereby minimizing waste.

Choosing the Right Manufacturer

When looking for a galvanized fence manufacturer, it is essential to consider several factors to ensure you partner with a reputable company

1. Experience and Expertise Choose a manufacturer with a proven track record in the fencing industry and expertise in galvanized products.

2. Quality Standards Ensure the manufacturer adheres to high-quality standards and certifications, ensuring that the finished product meets or exceeds expectations.

3. Customization Options A capable manufacturer should offer customization in terms of design, size, and coating thickness to cater to specific project needs.

4. Customer Reviews Researching customer testimonials and case studies can provide insight into the manufacturer’s reliability and product quality.

5. After-Sales Support A good manufacturer should offer robust after-sales support, including warranty information and assistance with any potential issues.

In conclusion, galvanized fences represent an enduring solution for those seeking durability and aesthetic appeal in their fencing options. Understanding the manufacturing process and the benefits of galvanized fencing can help customers make informed decisions. By carefully selecting a reputable manufacturer, you can ensure that your investment not only meets but exceeds your expectations for quality and performance.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025