-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 13, 2024 02:57 Back to list

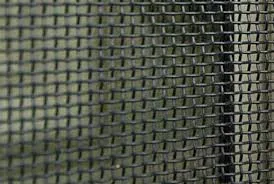

galvanized wire manufacturers

The Evolution and Importance of Galvanized Wire Manufacturers

Galvanized wire plays a pivotal role in various industries, from construction to agriculture, thanks to its durability and resistance to rust. As the demand for such products has grown, so has the number of galvanized wire manufacturers worldwide. This article aims to delve into the significance, processes, and innovations within the galvanized wire manufacturing industry.

Understanding Galvanization

Galvanization is a process by which steel or iron wire is coated in zinc to prevent corrosion. The resulting galvanized wire retains the strength of steel while gaining the protective properties of zinc, making it an ideal choice for outdoor applications. This process can be done through methods such as hot-dip galvanization or electro-galvanization, each offering different benefits. Hot-dip galvanization involves submerging the wire in molten zinc, creating a thicker and more durable coating, while electro-galvanization involves applying a zinc layer through electroplating, resulting in a smoother finish.

The Role of Galvanized Wire Manufacturers

Manufacturers of galvanized wire are essential to meet the growing demands of various sectors. They are responsible for producing a wide range of wire products, including fencing wire, barbed wire, and wire ropes, among others. The versatility of galvanized wire enables it to be used in construction, agriculture, telecommunications, and even in the automotive industry.

One of the primary focuses of galvanized wire manufacturers is ensuring the desired quality and durability of their products. This is achieved through rigorous testing and adherence to international standards. Quality assurance processes are vital, as the performance of galvanized wire can be significantly impacted by factors such as the thickness of the zinc coating and the manufacturing process itself.

Innovations in Manufacturing

galvanized wire manufacturers

As technology advances, galvanized wire manufacturers continue to adopt new techniques and equipment to improve efficiency and reduce costs. Automation is becoming increasingly prevalent, allowing for higher production rates and improved precision in cutting, coiling, and treating wire products. Additionally, modern manufacturing processes often prioritize sustainability, with many companies seeking to reduce waste and energy consumption during production.

Furthermore, the introduction of advanced coating methods is enhancing the corrosion resistance of galvanized wire. Some manufacturers are exploring new types of alloys and treatments that provide even better protection against environmental factors. Innovations in the monitoring and control of galvanization processes ensure that manufacturers can produce wire that meets or exceeds customer expectations.

Market Demand and Future Trends

The demand for galvanized wire is expected to grow in the coming years, driven by various factors such as urbanization, infrastructural development, and an increasing focus on sustainable building materials. As cities expand and the need for robust infrastructure grows, the importance of durable materials like galvanized wire cannot be overstated.

Moreover, the agricultural sector's reliance on galvanized wire for fencing and other applications will continue to contribute to market growth. Farmers appreciate galvanized wire's longevity and resistance to harsh weather conditions, making it a preferred choice for sustainable agricultural practices.

Conclusion

The world of galvanized wire manufacturers is dynamic and essential to various industries. By ensuring the production of high-quality galvanized wire, these manufacturers play a crucial role in supporting infrastructure development, agricultural practices, and more. As the industry evolves through technological advancements and increasing emphasis on sustainability, galvanized wire will remain a key player in ensuring that the needs of modern society are met effectively. Whether enhancing construction projects or supporting agricultural efforts, galvanized wire continues to be a staple of durability and reliability across the globe.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025