-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 20, 2025 03:24 Back to list

Welded Wire Mesh

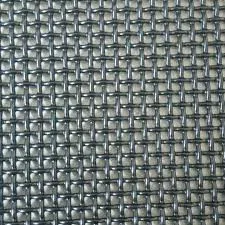

Galvanized woven wire mesh is a versatile and durable material used across numerous industries. This product, known for its strength and resistance to corrosion, is crafted by weaving wires into a mesh pattern and then galvanizing it to enhance its durability. In this expert review, we’ll delve into the unique aspects of galvanized woven wire mesh, drawing on industry experience and professional insights to highlight its applications, advantages, and purchasing tips.

Trust in galvanized woven wire mesh is further reinforced by the stringent industry standards and manufacturing processes that ensure consistent quality. Leading manufacturers test their products to meet or exceed these standards, providing assurance of the material's capability to withstand various stressors. For buyers, selecting a reputable supplier is crucial. Industry authorities suggest looking for suppliers who provide clear certification and product guarantees, ensuring that the wire mesh you invest in has been tested for its durability and compliance with industry norms. Expert opinions also highlight the sustainable nature of galvanized woven wire mesh. With growing awareness around environmental responsibility, industries are shifting towards materials that have a lower environmental impact. The galvanization process, as noted by sustainability experts, not only extends the product’s lifespan (reducing the need for frequent replacements) but is also recyclable, making it a more environmentally friendly choice compared to some alternatives. In conclusion, purchasing galvanized woven wire mesh involves considerations of quality, application, and sustainability. Drawing from professional insights and practical experiences, this material stands out for its resilience, versatility, and cost-effectiveness. Whether for industrial, agricultural, or personal use, galvanized woven wire mesh offers a tried-and-tested solution that meets a wide range of needs while offering long-term reliability. When sourcing this product, opting for reputable suppliers who adhere to recognized standards ensures that you receive the full benefits that this versatile material has to offer.

Trust in galvanized woven wire mesh is further reinforced by the stringent industry standards and manufacturing processes that ensure consistent quality. Leading manufacturers test their products to meet or exceed these standards, providing assurance of the material's capability to withstand various stressors. For buyers, selecting a reputable supplier is crucial. Industry authorities suggest looking for suppliers who provide clear certification and product guarantees, ensuring that the wire mesh you invest in has been tested for its durability and compliance with industry norms. Expert opinions also highlight the sustainable nature of galvanized woven wire mesh. With growing awareness around environmental responsibility, industries are shifting towards materials that have a lower environmental impact. The galvanization process, as noted by sustainability experts, not only extends the product’s lifespan (reducing the need for frequent replacements) but is also recyclable, making it a more environmentally friendly choice compared to some alternatives. In conclusion, purchasing galvanized woven wire mesh involves considerations of quality, application, and sustainability. Drawing from professional insights and practical experiences, this material stands out for its resilience, versatility, and cost-effectiveness. Whether for industrial, agricultural, or personal use, galvanized woven wire mesh offers a tried-and-tested solution that meets a wide range of needs while offering long-term reliability. When sourcing this product, opting for reputable suppliers who adhere to recognized standards ensures that you receive the full benefits that this versatile material has to offer.

Next:

Latest news

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025