-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 25, 2024 17:14 Back to list

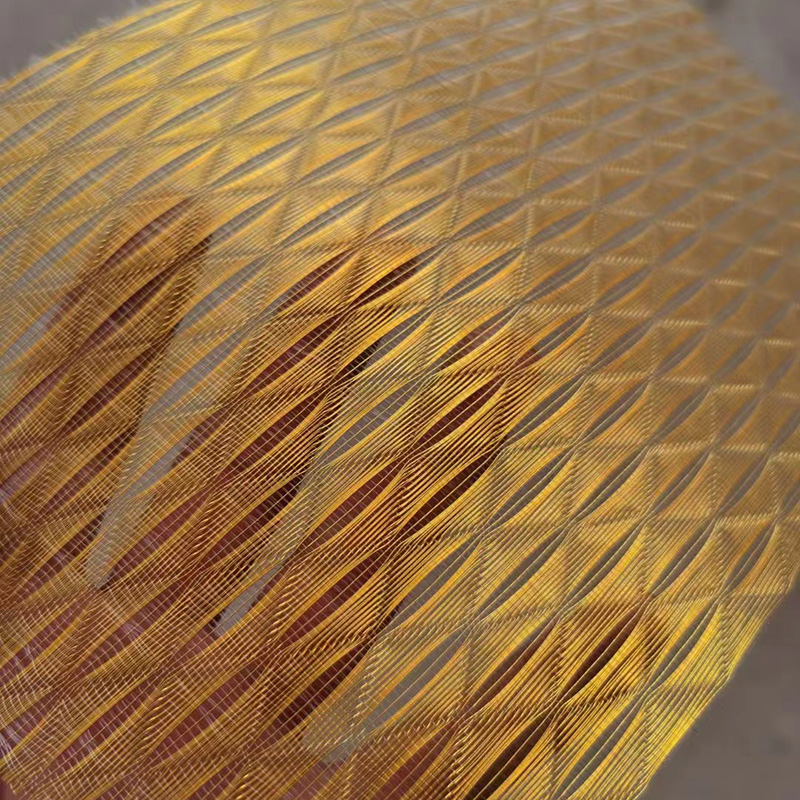

galvanized woven wire mesh factories

The Significance of Galvanized Woven Wire Mesh Factories in Modern Industry

In the realm of industrial manufacturing, galvanized woven wire mesh has emerged as a crucial material, finding applications in various sectors ranging from construction to agriculture

. The production of this essential component occurs primarily in specialized factories that have honed their techniques and technologies to deliver high-quality mesh products to the market.Galvanization is the process of applying a protective zinc coating to steel or iron to prevent rusting. When woven into mesh form, this treated material exhibits exceptional durability and longevity, making it ideal for numerous applications. The process typically involves hot-dipping or electro-galvanizing steel wires, which are then woven into mesh panels. The factories that focus on this type of mesh play a vital role in ensuring that the end products meet specific industry standards and customer expectations.

One of the key advantages of galvanized woven wire mesh is its resistance to corrosion. This characteristic is particularly beneficial in environments exposed to moisture or varying weather conditions. Consequently, industries such as agriculture, construction, and fencing rely heavily on this type of mesh. For instance, farmers often utilize galvanized wire mesh for fencing purposes to contain livestock and protect crops from pests. Similarly, construction firms apply it in concrete reinforcement applications, enhancing the structural integrity of buildings and bridges.

Moreover, the factories producing galvanized woven wire mesh are often equipped with advanced technologies that streamline production and enhance quality control. Automated weaving machines, precision cutting tools, and surface treatment processes contribute to the efficiency and consistency of the products. These technologies enable manufacturers to meet the increasing demand for wire mesh while ensuring that every batch adheres to rigorous quality standards.

galvanized woven wire mesh factories

Sustainability has become a critical consideration in manufacturing processes today. Many factories producing galvanized woven wire mesh are now adopting eco-friendly practices, such as recycling steel and using environmentally friendly galvanization methods. This shift not only reduces waste but also ensures that the production aligns with global sustainability goals. By minimizing their environmental footprint, these factories contribute to a more sustainable industrial ecosystem.

Another significant aspect of galvanized woven wire mesh factories is their contribution to local economies. These manufacturing units often provide considerable employment opportunities, supporting skilled and unskilled laborers alike. Through training programs and workshops, workers can develop essential skills in metalworking and manufacturing, thus improving their economic prospects. Additionally, as these factories thrive, they stimulate growth in associated industries such as logistics, distribution, and retail.

Furthermore, the global market for galvanized woven wire mesh continues to expand, driven by increasing urbanization and industrialization. Emerging economies are witnessing rapid growth in construction and infrastructure projects, which fuels demand for durable and reliable materials. Factories that can adapt to market trends and innovations will undoubtedly thrive, fostering competition and driving improvements within the industry.

In conclusion, galvanized woven wire mesh factories play an indispensable role in modern industrial operations. By providing a reliable, durable, and versatile product, they cater to diverse needs across various sectors. As the demand for quality materials increases, these factories are poised for growth, fostering innovation, sustainability, and economic development. The integral role they play in supporting agriculture, construction, and manufacturing highlights the importance of continued investment and advancement within this sector. Ultimately, the future of galvanized woven wire mesh is promising, and its factories will undoubtedly be at the forefront of this evolving landscape.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025