-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 30, 2024 22:23 Back to list

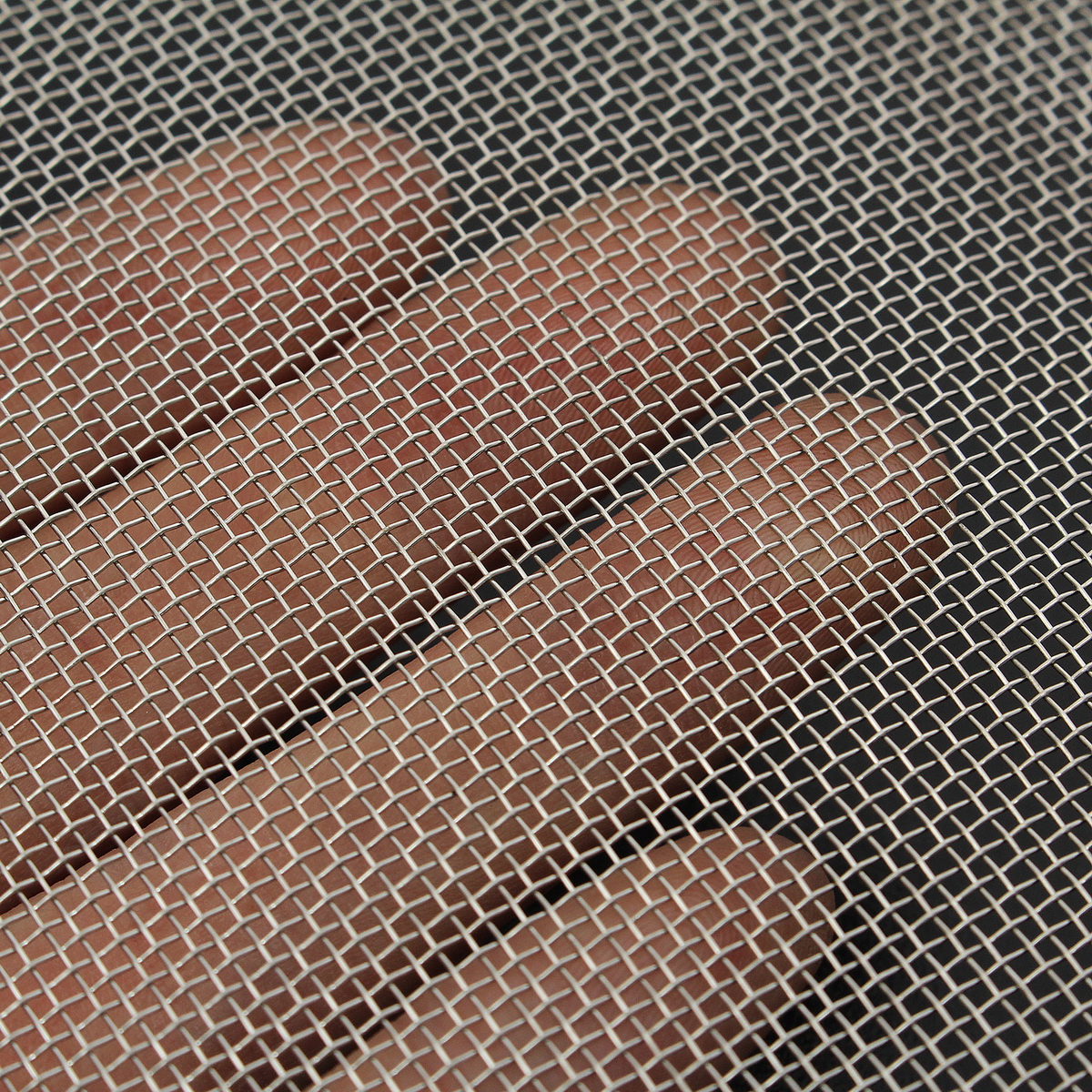

grating steel

Understanding Grating Steel Essential Material for Modern Applications

Grating steel, commonly referred to as steel grating, is a vital material widely used in construction, infrastructure, and various industrial applications. Its unique properties and design make it an optimal choice for a range of environments, offering strength, durability, and safety.

Steel grating consists of a series of parallel bars that are joined by perpendicular cross bars. This creates an open grid-like structure, which can support heavy loads while allowing the passage of light, air, and fluids. The manufacturing process typically involves hot-rolled or welded steel, ensuring that the grating can withstand significant stress and corrosion, particularly in industrial settings.

One of the most notable advantages of grating steel is its strength-to-weight ratio. Despite being lightweight, steel grating can support substantial loads, making it ideal for use in walkways, platforms, and staircases. This capability is particularly valuable in industrial environments, where heavy machinery and equipment are commonplace.

Another critical feature of steel grating is its slip resistance. Depending on the design, manufacturers can create surfaces that provide excellent traction, reducing the risk of slips and falls in workplaces and public areas. This property is especially important in locations that may become wet or greasy, as it enhances overall safety for workers and visitors.

grating steel

In terms of versatility, grating steel comes in various shapes, sizes, and styles

. Common types include welded, fibreglass-reinforced plastic (FRP), and riveted grating. Each type serves different applications and offers specific benefits. For example, welded steel grating is often used in heavy-duty scenarios, such as industrial flooring and platforms, whereas FRP grating provides a lightweight alternative that is resistant to chemicals and corrosion.The applications for steel grating are numerous. It is frequently utilized in factories, power plants, and wastewater treatment facilities for flooring and safety barriers. In addition, steel grating finds a role in commercial buildings, pedestrian walkways, and parking garages, contributing to both functional and aesthetic aspects of design.

Installation of steel grating is generally straightforward, which contributes to its efficiency in construction projects. The modular nature of grating allows it to be easily cut and assembled, facilitating customized solutions for specific needs. Moreover, maintenance is minimal, as regular cleaning and inspections are usually sufficient to keep it in good condition.

Environmental considerations are also important when discussing grating steel. Many manufacturers are adopting sustainable practices by utilizing recycled materials in the production of steel grating. This trend not only reduces waste but also promotes a circular economy that aligns with global sustainability goals.

In conclusion, grating steel is an indispensable material in today’s construction and industrial sectors. Its combination of strength, safety, and versatility makes it a preferred choice for various applications. As industries continue to evolve, the demand for innovative and sustainable materials like steel grating will likely increase, reaffirming its significant role in modern infrastructure and safety solutions. Whether for building codes or environmental considerations, understanding and leveraging the benefits of grating steel will be crucial for future developments.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025