-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 10, 2024 00:57 Back to list

Durable Wire Mesh Screen Suppliers for Heavy Duty Applications and Industrial Needs

Heavy Duty Wire Mesh Screens Manufacturers Key Players in Industrial Applications

Heavy duty wire mesh screens are indispensable components in various industries, including mining, construction, agriculture, and waste management. These robust screens are engineered to withstand extreme conditions and pressures, ensuring durability and reliability in high-performance applications. As industries continue to grow, the demand for high-quality wire mesh screens has surged, leading to the emergence of numerous manufacturers specializing in this space.

The Importance of Heavy Duty Wire Mesh Screens

Wire mesh screens serve a plethora of functions, ranging from filtering and sorting to separating and protecting. Heavy duty versions of these screens are designed to handle the rigors of industrial operations, making them ideal for tasks such as aggregating materials in quarries or processing waste in recycling facilities. Their design typically incorporates thicker wires and tighter mesh configurations to manage larger loads without compromising performance.

One of the primary advantages of heavy duty wire mesh screens is their versatility. They can be custom-manufactured to meet specific size and shape requirements, accommodating diverse operational needs. This adaptability is essential in industries where production varies, and specialized materials must be processed.

Key Manufacturers in the Industry

Several manufacturers have established themselves as leaders in the heavy duty wire mesh screens market. These companies prioritize innovation, quality, and customer satisfaction, ensuring their products meet the high standards required by various industries.

1. Wire Mesh Solutions, Inc. Known for its extensive range of wire mesh products, Wire Mesh Solutions focuses on creating screens that are both durable and efficient. They utilize advanced technology and manufacturing processes to produce heavy duty screens that are resistant to wear and tear.

2. A.G. Engineering With years of experience in the screen manufacturing industry, A.G. Engineering specializes in heavy duty screen solutions for mining and construction applications. Their commitment to quality is reflected in their rigorous testing processes and compliance with industry standards.

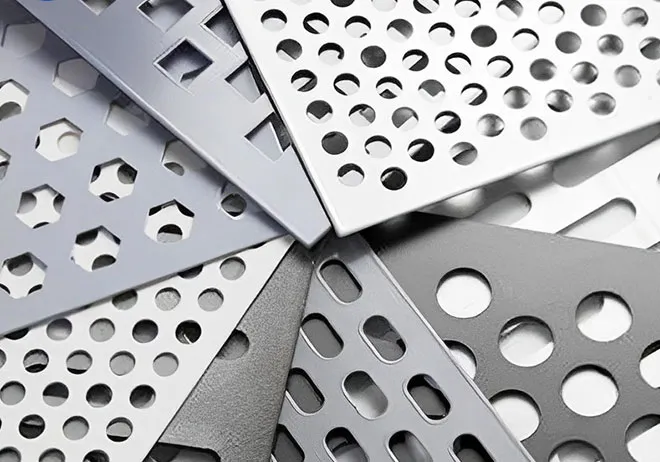

heavy duty wire mesh screens manufacturers

3. McNICHOLS Company McNICHOLS is renowned for its comprehensive inventory of wire mesh products. They provide customizable options that cater to specific industry needs, making them a top choice for many businesses requiring heavy duty wire mesh screens.

4. Roysons Corporation This manufacturer focuses on creating highly effective screening solutions, including heavy duty wire mesh. Their dedication to research and development ensures they remain at the forefront of technological advancements in the industry.

5. W.S. Tyler A pioneer in the manufacturing of woven wire mesh screens, W.S. Tyler has developed heavy duty products that are widely used in various sectors. Their innovative designs and high-quality materials set them apart as leaders in the mesh screen market.

The Future of Heavy Duty Wire Mesh Screens

As industries evolve, the need for more resilient and efficient heavy duty wire mesh screens will continue to grow. Manufacturers are focusing on advancements in material science to develop screens that can endure higher loads and resist corrosion, especially in challenging environments. The integration of automation and smart technology may further enhance the manufacturing process, leading to products that are not only stronger but also more precise in their applications.

In addition, the increasing focus on sustainability and recycling will likely drive innovation in wire mesh products. Manufacturers are beginning to explore environmentally friendly materials and production techniques, aligning with global efforts to reduce waste and promote sustainable practices.

Conclusion

Heavy duty wire mesh screens are vital in ensuring the smooth operation of various industrial processes. With several key manufacturers leading the way, the market for these products is poised for continued growth and innovation. As industries demand higher quality and more specialized solutions, manufacturers will need to adapt and evolve, setting the stage for a more durable and efficient future in heavy duty wire mesh applications.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025