-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 12, 2024 13:02 Back to list

hexagonal wire netting manufacturer

The Importance of Hexagonal Wire Netting in Modern Manufacturing

Hexagonal wire netting, commonly known as chicken wire, is a versatile product widely used in various industries. As a leading hexagonal wire netting manufacturer, it’s crucial to understand the many applications, benefits, and manufacturing processes involved in creating this essential material.

Understanding Hexagonal Wire Netting

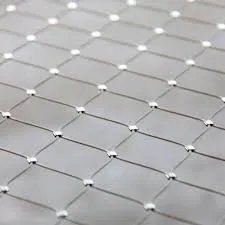

Hexagonal wire netting is constructed from thin strands of wire woven together to form a mesh pattern of hexagons. This design provides strength and durability, making it an ideal material for numerous applications. The netting is typically made from galvanized steel, which helps to prevent rust and corrosion. Some manufacturers also offer plastic-coated options for additional protection and aesthetic appeal.

One of the main attributes of hexagonal wire netting is its lightweight nature, making it easy to handle and install. The flexibility of the material allows it to be bent and shaped, making it suitable for various installations, from garden fences to industrial enclosures.

Applications of Hexagonal Wire Netting

The applications of hexagonal wire netting are diverse. In agriculture, it is commonly used for fencing around poultry farms, gardens, and other livestock areas to protect animals from predators. The open design allows for good airflow and visibility while keeping chickens and other small animals contained.

In construction, hexagonal wire netting is utilized in reinforcing concrete and other building materials. It serves to provide added strength and stability to structures, making it an essential component in modern construction practices. The mesh is often used in erosion control projects as well, helping to stabilize soil and prevent erosion in landscaping and building sites.

In residential areas, the netting can be used for decorative purposes. Gardeners often use hexagonal wire netting to create trellises for climbing plants or to protect delicate flowers from animals. Additionally, it is sometimes employed in crafting and DIY projects due to its unique look and functionality.

hexagonal wire netting manufacturer

Benefits of Choosing Hexagonal Wire Netting

Selecting hexagonal wire netting offers several advantages. Its durability ensures a long lifespan, reducing the need for frequent replacements. The lightweight nature of the material makes it convenient to transport and install, while the various sizes available cater to different needs.

Moreover, the cost-effectiveness of hexagonal wire netting makes it an attractive option for both large-scale projects and smaller applications. In bulk, the material can be sourced at competitive prices, allowing businesses to reduce overhead costs without compromising quality.

The Manufacturing Process

The manufacturing process of hexagonal wire netting is intricate yet efficient. It begins with the selection of high-quality wire, which is then drawn to the desired thickness. The wire is subsequently galvanized to enhance its resistance to corrosion.

Once the wire preparation is complete, it is woven into the hexagonal pattern using specialized machinery. This ensures a consistent and strong mesh that meets industry standards for strength and durability. Finally, the netting is cut into manageable rolls and prepared for distribution.

Conclusion

In conclusion, hexagonal wire netting plays a vital role in a sphere of applications, from agriculture to construction and beyond. As a hexagonal wire netting manufacturer, prioritizing quality and versatility in design is essential to meet the various needs of customers across different industries. By understanding the properties, benefits, and manufacturing processes of this remarkable material, businesses can ensure they provide high-quality products that stand the test of time, proving that hexagonal wire netting is indeed an indispensable tool in modern manufacturing.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025