-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jul . 28, 2024 00:07 Back to list

High-Quality Steel Grating Drainage Covers from Leading Manufacturers for Optimal Water Management Solutions

Steel Grating Drainage Cover Factories An Overview

Steel grating drainage covers serve as essential components in modern infrastructure, providing efficient drainage solutions while ensuring safety and durability. These products are manufactured in specialized factories that focus on the design, engineering, and production of high-quality steel grates intended for various applications, including roads, walkways, and industrial settings. This article will delve into the processes, benefits, and importance of steel grating drainage cover factories, and how they play a crucial role in urban development and infrastructure management.

Manufacturing Process

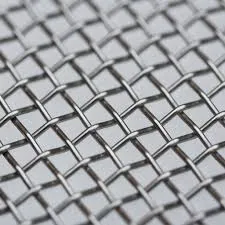

The production of steel grating drainage covers involves several stages, beginning with material selection. Typically, factories utilize carbon steel, stainless steel, or galvanized steel, chosen for their strength, corrosion resistance, and longevity. Once the appropriate materials are selected, the manufacturing process commences with cutting the steel into specific shapes and sizes to meet designated specifications.

After cutting, the steel pieces undergo a welding process, where they are joined to create a grid pattern. This welding ensures that the grating has the required strength to withstand heavy loads and environmental conditions. Post-weld, the grating may be subjected to machining processes to achieve precise dimensions and a smooth finish.

The final stages of production involve quality control, where the grating covers are thoroughly inspected for defects and weaknesses. Additionally, they may receive surface treatments, such as galvanization or powder coating, to enhance their durability and resistance to rust. Factories often collaborate with engineers and designers to ensure their products meet industry standards and regulations, fostering innovation while adhering to safety protocols.

Advantages of Steel Grating Drainage Covers

steel grating drainage cover factories

Steel grating drainage covers offer several advantages that make them a popular choice in various applications. First and foremost, their strength and load-bearing capacity make them ideal for environments subjected to heavy traffic, such as highways and industrial sites. The open design allows for efficient water drainage, preventing flooding and water accumulation that can lead to hazardous conditions.

Moreover, steel grating is highly customizable. Factories can produce grates in various shapes, sizes, and load ratings to meet specific project requirements. This versatility means they are suitable for residential, commercial, and industrial applications alike.

Another significant advantage is the longevity of steel grating. Unlike traditional concrete or plastic alternatives, steel grates are resistant to impacts and wear, ensuring they maintain their integrity over time. Additionally, they require minimal maintenance, making them a cost-effective solution for property owners and municipal authorities.

Environmental Considerations

In an era where sustainability and environmental consciousness are becoming increasingly important, steel grating drainage cover factories are making strides to minimize their ecological footprint. Many manufacturers have adopted recycling practices, using reclaimed steel and minimizing waste during production. Additionally, using durable materials reduces the need for frequent replacements, contributing to lower resource consumption over time.

Conclusion

Steel grating drainage cover factories play a vital role in creating robust and efficient drainage systems that are crucial for urban infrastructure. The combination of strength, durability, and design flexibility makes steel grating an unrivaled choice for managing stormwater and ensuring pedestrian safety. As urban areas continue to expand and evolve, the importance of reliable drainage solutions will only grow, highlighting the indispensable contributions of these specialized manufacturing facilities in building a sustainable future.

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025