-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 19, 2025 07:29 Back to list

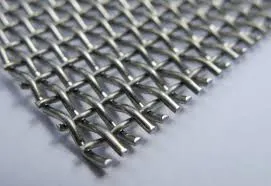

stainless steel grating

High quality stainless steel grating has steadily cemented its position as an essential component across various industries, offering a unique blend of durability, efficiency, and aesthetic appeal. Its application spans diverse sectors, including architecture, manufacturing, food processing, and wastewater management. This article delves into the critical advantages and applications of high-quality stainless steel grating, establishing its importance in modern industrial and architectural practices.

Hygiene and cleanliness are yet another reason why stainless steel grating is favored, especially in sectors like food processing or healthcare premises. Its inherent resistance to bacteria and ease of cleaning make it an excellent choice for environments requiring stringent hygiene standards. The smooth, non-porous surface prevents the buildup of contaminants and ensures compliance with health regulations. Aesthetic versatility adds to the strengths of high-quality stainless steel grating. Its sleek, modern appearance complements contemporary architectural styles, making it a popular choice for projects where visual impact constitutes a large part of the project’s goals. Its reflective surface can enhance space by providing a brighter look, making it suitable for modern office complexes and public infrastructures. Globally, increasing awareness of sustainability and environmental impacts have positioned high-quality stainless steel as a leader in eco-friendly construction materials. It is fully recyclable, reducing waste and contributing to cost savings on raw materials. The longevity of stainless steel products also means fewer replacements and reduced resource consumption over time, aligning with sustainable building practices. Industry experts consistently recommend high-quality stainless steel grating for projects where structural integrity, safety, and aesthetic quality are non-negotiable. Its application can be found in numerous high-profile structures and facilities, often approved by architect and engineering authorities due to its proven performance metrics and compliance with regulatory standards. In conclusion, the application of high-quality stainless steel grating provides unmatched benefits across a spectrum of industries. Its durability, strength, versatility, and sustainability make it a sought-after solution for modern engineering challenges. As industries increasingly pivot towards materials that marry performance with sustainability, stainless steel grating emerges as a material of choice, underpinning tomorrow’s infrastructure with resilience and style.

Hygiene and cleanliness are yet another reason why stainless steel grating is favored, especially in sectors like food processing or healthcare premises. Its inherent resistance to bacteria and ease of cleaning make it an excellent choice for environments requiring stringent hygiene standards. The smooth, non-porous surface prevents the buildup of contaminants and ensures compliance with health regulations. Aesthetic versatility adds to the strengths of high-quality stainless steel grating. Its sleek, modern appearance complements contemporary architectural styles, making it a popular choice for projects where visual impact constitutes a large part of the project’s goals. Its reflective surface can enhance space by providing a brighter look, making it suitable for modern office complexes and public infrastructures. Globally, increasing awareness of sustainability and environmental impacts have positioned high-quality stainless steel as a leader in eco-friendly construction materials. It is fully recyclable, reducing waste and contributing to cost savings on raw materials. The longevity of stainless steel products also means fewer replacements and reduced resource consumption over time, aligning with sustainable building practices. Industry experts consistently recommend high-quality stainless steel grating for projects where structural integrity, safety, and aesthetic quality are non-negotiable. Its application can be found in numerous high-profile structures and facilities, often approved by architect and engineering authorities due to its proven performance metrics and compliance with regulatory standards. In conclusion, the application of high-quality stainless steel grating provides unmatched benefits across a spectrum of industries. Its durability, strength, versatility, and sustainability make it a sought-after solution for modern engineering challenges. As industries increasingly pivot towards materials that marry performance with sustainability, stainless steel grating emerges as a material of choice, underpinning tomorrow’s infrastructure with resilience and style.

Latest news

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025