-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 15, 2024 09:25 Back to list

High-Quality Hot Dip Galvanized Wire Manufacturers | Durable & Corrosion-Resistant Solutions

The Importance of Hot-Dip Galvanized Wire Factories

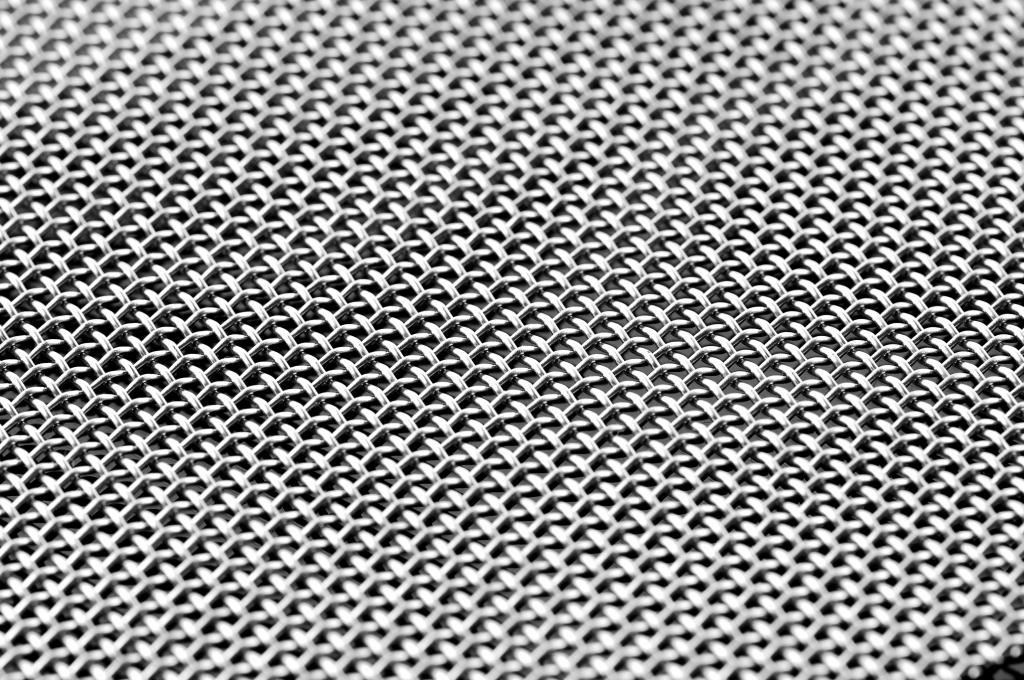

Hot-dip galvanizing is a crucial process employed in the manufacturing of galvanized wire, which is widely used in various industries due to its enhanced durability and resistance to corrosion. The process involves immersing steel wire in molten zinc, creating a protective layer that significantly improves the wire's lifespan and performance in harsh environments. With increasing demand for high-quality galvanized products, the role of hot-dip galvanized wire factories has become ever more critical in the manufacturing sector.

The Importance of Hot-Dip Galvanized Wire Factories

The operational efficiency of hot-dip galvanized wire factories plays a vital role in producing quality products. These factories utilize advanced technologies to optimize the galvanizing process, ensuring uniform coating and minimizing waste. Continuous innovation in techniques and machinery enhances productivity while maintaining the superior characteristics of the wire. High-quality control standards are essential within factories to ensure that the final product meets safety and performance regulations, giving customers confidence in their purchases.

hot dip galvanized wire factories

Environmental considerations are also becoming increasingly important in the operations of hot-dip galvanized wire factories. Many manufacturers are adopting sustainable practices, such as recycling used zinc and minimizing energy consumption during the manufacturing process. By implementing eco-friendly measures, these factories can not only reduce their carbon footprint but also appeal to a growing market of environmentally conscious consumers.

Furthermore, the global market for hot-dip galvanized wire continues to expand, driven by urbanization, infrastructure development, and increasing agricultural activities. Countries investing in infrastructure projects are generating significant demand for reliable wire products, creating growth opportunities for manufacturers. This trend highlights the need for hot-dip galvanized wire factories to scale up production capabilities while maintaining the quality of their products.

In conclusion, hot-dip galvanized wire factories are integral to producing resilient wire products that meet the diverse needs of various industries. As technology advances and environmental awareness grows, these factories must adapt and innovate to stay competitive in a dynamic global market. The importance of high-quality hot-dip galvanized wire cannot be overstated, as it serves as the backbone for countless applications that contribute to modern infrastructure and agriculture.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025