-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 27, 2024 11:34 Back to list

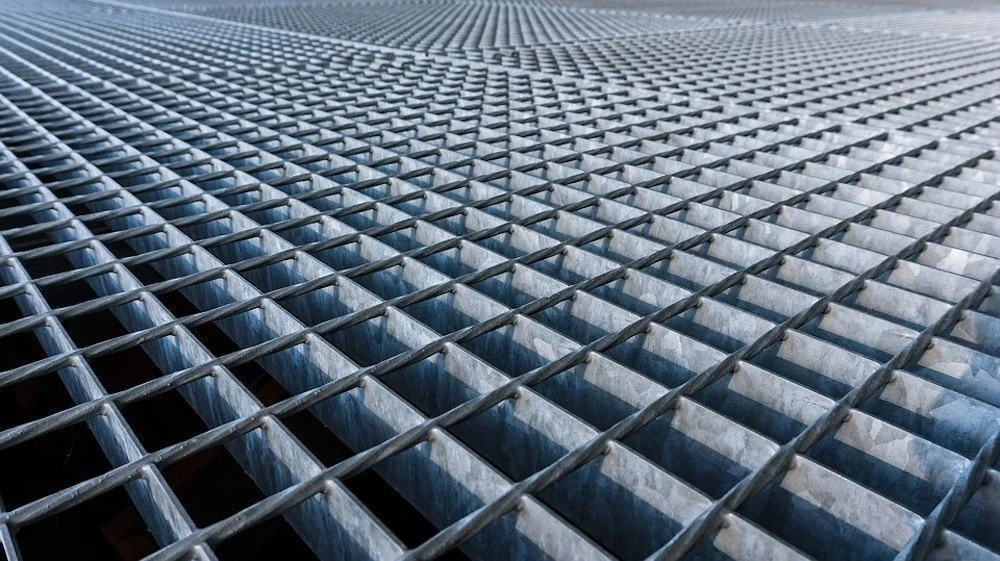

Leading Manufacturers of Durable Iron Mesh Solutions for Various Applications

The Role of Iron Mesh Manufacturers in Modern Industry

Iron mesh, a versatile and durable material, is a cornerstone in various industries ranging from construction to agriculture. As urbanization and industrial development continue to accelerate, the demand for high-quality iron mesh products is on the rise. This demand highlights the critical role played by iron mesh manufacturers in ensuring that diverse industries have access to robust and reliable materials.

Iron mesh is primarily made from high-quality iron, which is processed and woven into mesh sheets or rolls. It is known for its strength, resistance to corrosion, and ability to withstand heavy loads, making it an ideal choice for numerous applications. Manufacturers across the globe are continually innovating to enhance the properties of iron mesh, including improved longevity and adaptability to different environmental conditions.

One of the primary applications of iron mesh is in the construction industry. Iron mesh is often used in reinforcing concrete structures, as it provides added strength and support. Manufacturers supply various types of mesh, including welded wire mesh and expanded metal mesh, each tailored for specific construction needs. The versatility of iron mesh allows engineers and builders to utilize it in everything from roads and bridges to residential buildings and industrial facilities.

In agriculture, iron mesh finds its way into fencing and animal enclosures. Farmers and ranchers rely on strong, weather-resistant fencing to protect their livestock and crops from predators. Manufacturers produce different gauges and sizes of iron mesh to cater to these needs, ensuring that agricultural operations can run smoothly and securely. The durability of iron mesh also means that it requires less frequent replacement, making it a cost-effective solution for farmers.

iron mesh manufacturers

Moreover, iron mesh manufacturers are increasingly focusing on sustainability. With an emphasis on reducing carbon footprints, many companies are adopting eco-friendly practices in their production processes. This includes sourcing materials from sustainable suppliers and implementing recycling programs for metal scraps. The move towards sustainable manufacturing not only addresses environmental concerns but also appeals to a growing market of eco-conscious consumers.

Technological advancements are also playing a significant role in the evolution of iron mesh production. Modern manufacturers are using cutting-edge machinery and techniques to produce mesh with higher precision and improved specifications. This includes automated weaving machines that increase efficiency and reduce human error. Additionally, advancements in coatings and treatments can enhance the corrosion resistance of iron mesh, extending its lifespan and performance in harsh environments.

Quality control is another crucial aspect of iron mesh manufacturing. Reputable manufacturers implement stringent quality assurance measures to ensure that their products meet industry standards and customer specifications. This involves rigorous testing for strength, durability, and resistance to environmental factors. By maintaining high quality, manufacturers help build trust with their clients and ensure the long-term success of their projects.

In conclusion, iron mesh manufacturers play an indispensable role in supporting various industries by providing essential materials that contribute to the strength, safety, and efficiency of their operations. As demand continues to grow and technology evolves, these manufacturers are poised to meet the challenges of the future while adhering to sustainability and quality standards. Their commitment to innovation ensures that iron mesh will remain a vital component across sectors, promoting growth and development in an ever-changing industrial landscape.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025