-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 10, 2024 07:54 Back to list

Durable Iron Welded Wire Mesh for Various Applications and Projects

The Versatility of Iron Welded Wire Mesh

Iron welded wire mesh is a fundamental material used in various industries, renowned for its durability, strength, and versatility. This extensively utilized product is made by welding together iron wires to form a grid or mesh pattern, which can be tailored to suit specific applications. In this article, we will explore the characteristics, manufacturing process, and diverse applications of iron welded wire mesh.

Characteristics of Iron Welded Wire Mesh

One of the most compelling features of iron welded wire mesh is its strength. The welding process ensures that the intersections of the wires are incredibly strong, offering enhanced structural integrity. As it is produced using high-quality iron, the mesh exhibits excellent resistance to mechanical stress, making it suitable for applications requiring robust materials.

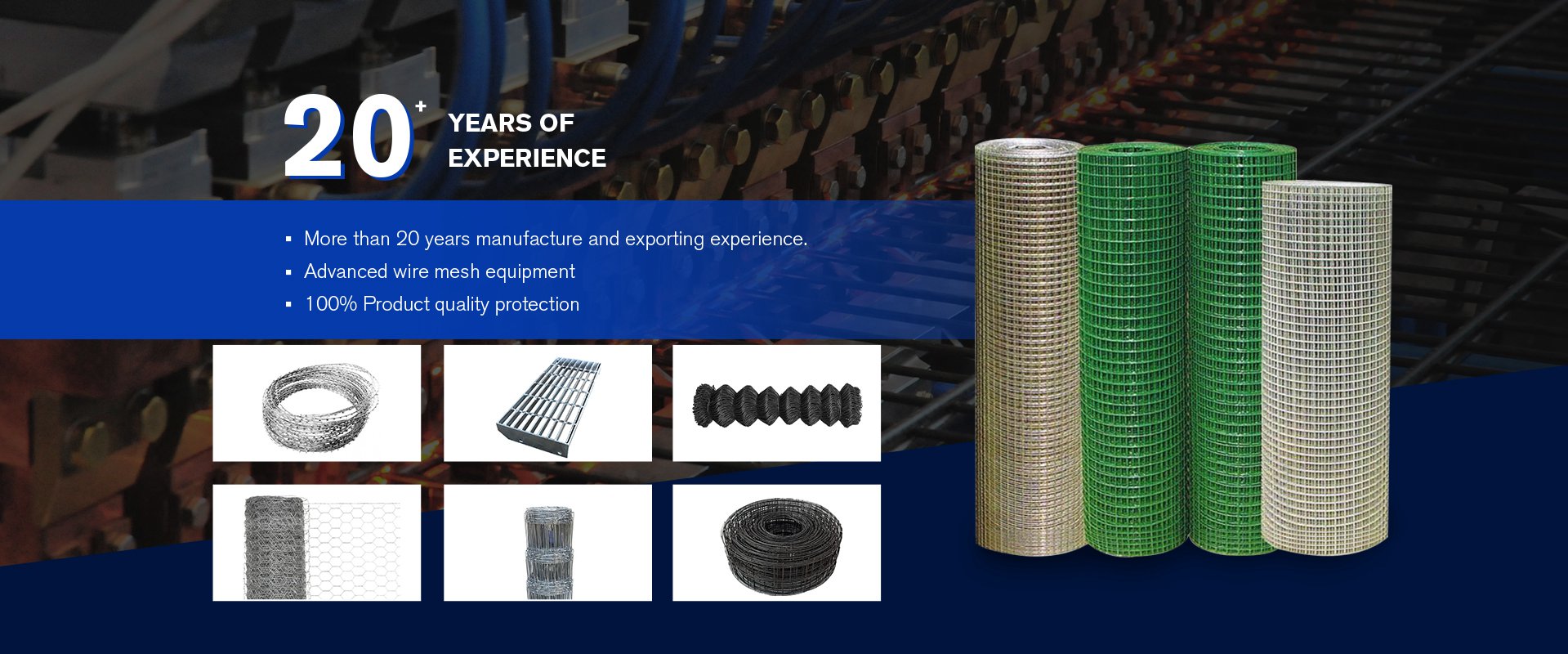

Additionally, iron welded wire mesh is known for its corrosion resistance, especially when coated with materials like galvanized or PVC. These coatings provide a protective layer that prevents rusting and extends the lifespan of the mesh, making it ideal for outdoor and industrial applications where exposure to the elements is a concern.

Another significant advantage of iron welded wire mesh is its flexibility in design. Manufacturers can produce a variety of mesh sizes and wire diameters according to customer specifications. This customization allows for a wide range of uses, from fencing and security barriers to reinforcement in construction projects.

Manufacturing Process

The manufacturing process of iron welded wire mesh involves several steps. Initially, high-quality iron wire is drawn to the desired gauge. The wires are then arranged in a predetermined configuration, either in a square or rectangular pattern. Once the desired layout is achieved, the wires are welded together at the intersections using electric welding techniques.

iron welded wire mesh

This welding process is critical, as it ensures that the mesh maintains its strength while providing a neat and uniform appearance. Afterwards, the mesh may undergo additional treatments such as galvanization, where it is coated with zinc to prevent corrosion, or a PVC coating for added weather resistance and aesthetic appeal.

Applications of Iron Welded Wire Mesh

Iron welded wire mesh is employed in a multitude of applications across different sectors. In the construction industry, it is often used for reinforcing concrete, providing stability and strength to buildings, roads, and bridges. The mesh serves as a tension distribution element, minimizing the risk of cracks and structural failures.

In agriculture, iron welded wire mesh is utilized for fencing to protect crops and livestock from wild animals. Its sturdy construction offers a reliable solution for securing agricultural areas, ensuring that animals cannot escape or intrude upon cultivated lands.

Moreover, in industrial settings, the mesh is used for creating safety barriers, storage racks, and shelving units. The inherent strength of the welded mesh makes it an ideal choice for handling heavy loads, ensuring safety and efficiency in warehouses and manufacturing facilities.

The mesh also finds application in residential settings, where it is commonly used in garden fencing, window screens, and as decorative elements in landscaping projects. Its aesthetic versatility combined with functional strength makes it an attractive option for homeowners looking to enhance both security and beauty.

Conclusion

In summary, iron welded wire mesh is an incredibly versatile material that plays a crucial role in various sectors. Its strength, durability, and adaptability make it an essential product in construction, agriculture, industry, and even residential applications. With advancements in manufacturing techniques and the availability of varied designs, the future of iron welded wire mesh looks promising, ensuring it will remain a key component in numerous projects for years to come.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025