-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 16, 2024 09:18 Back to list

Stainless Steel Perforated Metal Mesh Supplier | Quality Mesh Solutions

The Rise of Stainless Steel Perforated Metal Mesh An Essential Supply for Various Industries

In today’s world of engineering and design, versatility and durability are essential. One material that has gained significant traction in various applications is stainless steel perforated metal mesh. As industries strive for efficiency and aesthetics, the demand for high-quality metal supplies has soared. This article delves into the advantages of perforated metal mesh, its various applications, and the vital role suppliers play in meeting these demands.

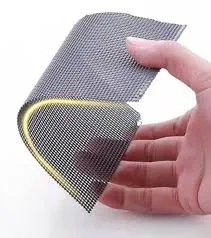

Stainless steel perforated metal mesh is created by puncturing a variety of patterns into sheets or rolls of stainless steel. This process results in a unique combination of strength, flexibility, and design potential. The stainless steel formulation provides resistance to rust and corrosion, making it ideal for both indoor and outdoor use. Additionally, its durability ensures that products maintain structural integrity over time, even in harsh environmental conditions.

One of the biggest advantages of stainless steel perforated metal mesh is its ability to enhance airflow while maintaining security and strength. This makes it a popular choice in architectural applications. Designers and architects are increasingly incorporating it into buildings, facades, and decorative elements. The perforated design allows natural light to illuminate spaces while providing privacy and protection from the elements. The aesthetic possibilities are vast, as the mesh can be customized with different hole patterns and sizes, adapting to any design vision.

In industrial applications, stainless steel perforated metal mesh serves multiple functions. It is commonly used in filtration systems, where it helps in separating particles from liquids and gases. The durability of stainless steel ensures that these systems remain effective, reducing downtime and maintenance costs. Additionally, perforated metal mesh is utilized in manufacturing processes, providing strength and stability in components such as screens, guards, and conveyor belts.

metal stainless steel perforated metal mesh supplier

Another critical advantage of stainless steel perforated metal mesh is its lightweight property combined with substantial load-bearing capabilities. This feature makes it a robust choice for various engineering projects, from scaffolding to industrial equipment. The mesh can also be easily fabricated into different shapes and sizes, allowing for seamless integration into complex designs.

The role of suppliers in the perforated metal mesh market is pivotal. A reliable supplier ensures access to high-quality materials that meet industry standards. They offer expertise in helping clients select the appropriate mesh size, thickness, and pattern based on specific applications. Furthermore, advanced suppliers provide customization options, allowing clients to tailor their orders to suit unique project requirements.

As industries continue to evolve, the demand for stainless steel perforated metal mesh is expected to grow. Technological advancements and innovative design trends will push the boundaries of its applications, making it an even more integral component in various sectors, including construction, automotive, and aerospace.

In conclusion, stainless steel perforated metal mesh stands out as a multifunctional and aesthetic material that caters to diverse industries. Its increasing popularity highlights the importance of quality suppliers who can deliver the right products to meet market demands. With its combination of strength, versatility, and aesthetic appeal, stainless steel perforated metal mesh is undoubtedly a valuable asset for both manufacturers and designers alike. As we continue to innovate, the possibilities for this remarkable material are boundless, paving the way for exciting new applications in the future.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025