-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 14, 2024 18:55 Back to list

metal mesh supplier

The Benefits and Applications of Metal Mesh A Comprehensive Guide for Suppliers

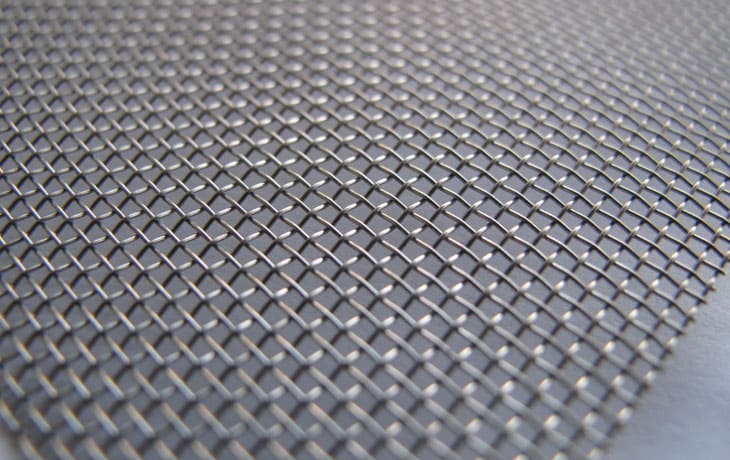

Metal mesh is a versatile material that has found its way into numerous industries, owing to its unique characteristics and benefits. As a metal mesh supplier, understanding these advantages and the various applications of metal mesh can help in catering to a diverse clientele, enhancing your business potential significantly.

Understanding Metal Mesh

Metal mesh is typically made from various metals including stainless steel, aluminum, brass, or carbon steel, and can be produced in different shapes and sizes. The manufacturing processes may involve weaving, welding, or stamping to create a network of interconnected wires or sheets. The resulting product boasts a variety of features such as strength, durability, and resistance to corrosion, which makes it suitable for both industrial and commercial applications.

Benefits of Metal Mesh

1. Strength and Durability One of the primary benefits of metal mesh is its high strength-to-weight ratio. This characteristic allows it to withstand heavy loads while being lightweight, making it ideal for structural applications.

2. Corrosion Resistance Depending on the metal used, metal mesh can exhibit excellent resistance to corrosion. For instance, stainless steel mesh is frequently used in environments where exposure to moisture or chemicals is a concern.

3. Versatility Metal mesh can be customized in terms of aperture size, wire diameter, and weave pattern. This flexibility allows it to be tailored for specific applications, whether in construction, agriculture, or manufacturing.

4. Air and Light Permeability Metal mesh offers excellent airflow and light penetration, making it a popular choice for architectural designs where aesthetics and functionality must be balanced.

5. Easy to Maintain Metal mesh does not require extensive maintenance, as it is easy to clean and does not accumulate dust and debris like other materials may.

Diverse Applications of Metal Mesh

metal mesh supplier

The uses of metal mesh are extensive and span various industries

1. Construction and Architecture Metal mesh is utilized in building facades, fences, and ceilings, providing both structural integrity and aesthetic appeal. Its ability to allow airflow and light makes it perfect for modern architectural designs.

2. Industrial Manufacturing It is widely used in industrial settings for filtration, separation, and protection. For example, it can serve as protective barriers, machine guarding, or even in material handling systems.

3. Agriculture In agriculture, metal mesh can be used for fencing and enclosures to protect crops and livestock. Additionally, it is employed in irrigation systems and as trellising for climbing plants.

4. Transportation Metal meshes are essential in the automotive and aerospace industries for applications such as sound dampening, ventilation, and protection against foreign objects.

5. Food and Beverage Industry Food processing plants often use stainless steel mesh for sieving, filtering, and food preparation, ensuring hygiene and compliance with safety regulations.

Selecting the Right Supplier

As a metal mesh supplier, it is crucial to understand your clients' needs and provide materials that meet their specific requirements. Quality assurance, competitive pricing, and timely delivery are key factors that can set you apart in a crowded market. Additionally, you must be knowledgeable about the different types of metal mesh and their applications, enabling you to offer expert advice to your customers.

Conclusion

Metal mesh is an invaluable material with a plethora of applications across various sectors. By recognizing its benefits and understanding the diverse needs of your clientele, you as a metal mesh supplier can position yourself as a key player in the market. Whether your focus is on serving the construction industry, agricultural needs, or specialized manufacturing processes, the potential for growth and innovation within this realm is vast. As industries continue to evolve and demand more versatile, durable solutions, your expertise in metal mesh will be instrumental in meeting these challenges head-on, ensuring your place at the forefront of the industry.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025