-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 23, 2024 18:47 Back to list

metal perforated plate factories

The Significance of Metal Perforated Plate Factories

Metal perforated plates have become essential components in various industries, playing a crucial role in architecture, manufacturing, and environmental management. With an increasing demand for innovative and versatile materials, metal perforated plate factories have risen to prominence. These factories specialize in the design, production, and distribution of perforated metal sheets, serving a wide array of applications.

Understanding Perforated Metal Plates

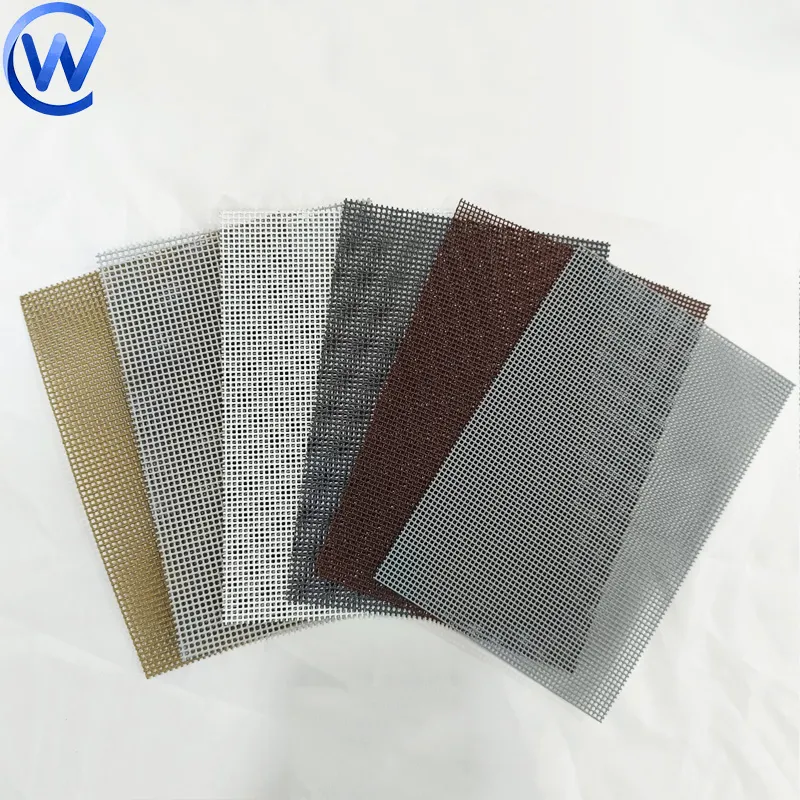

Perforated metal plates are sheets of material with a series of holes punched through them. These holes can come in various shapes, sizes, and patterns, allowing for a multitude of design possibilities. The perforation process not only enhances the aesthetic appeal of the metal but also offers functional benefits, such as improved air and light circulation, sound attenuation, and filtration capabilities. Common materials used for these plates include steel, aluminum, copper, and various alloys.

Applications Across Industries

The versatility of perforated metal plates makes them suitable for a broad spectrum of applications. In the construction industry, these plates are widely used for facades, ceilings, and wall cladding. Their aesthetic quality combined with functional properties allows architects to achieve both beauty and practicality in their designs.

In the manufacturing sector, perforated plates are employed in machinery, equipment screens, and as components for filtration systems. Their ability to withstand high temperatures and corrosive environments makes them ideal for use in diverse settings, from food processing to petrochemical industries. Moreover, in environmental applications, perforated plates play a vital role in wastewater treatment, air filtration, and sound reduction systems, contributing to a cleaner and healthier environment.

The Role of Metal Perforated Plate Factories

Metal perforated plate factories are pivotal in the supply chain, ensuring the availability of high-quality materials to meet industry demands. These factories utilize advanced technology and machinery to produce perforated sheets efficiently. CNC (Computer Numerical Control) machines and laser cutting technologies allow for precise hole placement and various hole designs, catering to specific customer requirements.

Additionally, many factories prioritize sustainability in their operations. By employing recycled materials and eco-friendly processes, these manufacturers reduce their carbon footprint while meeting the growing demand for sustainable practices in production.

metal perforated plate factories

Quality Control and Standards

Quality control is paramount in the production of perforated metal plates. Factories adhere to stringent quality standards to ensure that their products meet industry regulations. From material selection to the final inspection, every stage of the manufacturing process is monitored to maintain consistency and reliability. Certifications such as ISO 9001 demonstrate a commitment to quality management, reassuring customers of the product's durability and performance.

Innovations and Trends

As technology advances, metal perforated plate factories continue to innovate. Customization has become a significant trend, with many manufacturers offering tailor-made solutions to meet unique client specifications. Whether it’s a specific hole pattern, material type, or finish, factories are equipped to deliver products that stand out in terms of functionality and design.

Furthermore, automation in manufacturing processes has led to enhanced efficiency and reduced production costs. This allows factories to respond quickly to market demands, maintaining competitive pricing while ensuring high-quality output.

Global Impact and Future Outlook

The growth of metal perforated plate factories is not just a local phenomenon; it reflects a global trend in construction, manufacturing, and environmental management. As industries continue to evolve and seek materials that are both functional and aesthetically appealing, the demand for perforated metal plates is anticipated to rise.

Looking ahead, the future of metal perforated plate factories appears promising. With ongoing technological advancements, a push for sustainability, and a growing variety of applications, these factories are well-positioned to meet the challenges and opportunities that lie ahead. As architects, manufacturers, and environmentalists search for innovative solutions, metal perforated plates will remain a cornerstone of modern design and engineering.

In conclusion, metal perforated plate factories play a critical role in shaping the future of various industries. By combining functionality with style, they contribute to the development of smarter, more sustainable environments.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025