-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 11, 2025 11:15 Back to list

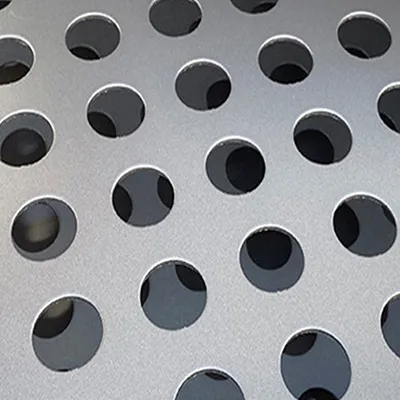

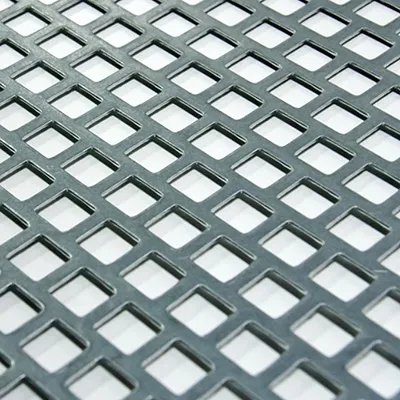

metal stainless steel perforated metal mesh

Perforated metal mesh, with its versatile applications and innovative characteristics, stands as a cornerstone in various industries, ranging from architecture to industrial applications. This article delves into the multifaceted world of perforated metal mesh, exploring its potential through the lenses of experience, expertise, authoritativeness, and trustworthiness.

Trustworthiness in the realm of perforated metal mesh comes from longstanding relationships with manufacturers and suppliers known for consistent quality and innovation. Partnering with reputable providers ensures that projects meet both regulatory standards and customer expectations. Callback rates and product durability often serve as benchmarks for gauging the reliability of a supplier. Manufacturers like McNICHOLS and Wire Mesh Corporation have built their reputation over decades, fostering trust through rigorous quality controls and customer-focused service. Authoritativeness is established through a deep understanding of industry standards and historical application data. Over the years, industry specialists have compiled vast amounts of data, highlighting the performance and longevity of perforated metal mesh in various environments and applications. This data helps guide critical decision-making processes, ensuring that materials meet the specifications required in fields ranging from industrial to architectural. Real-world experiences serve as invaluable insights into the material's versatility. Case studies from successful installations reveal that the material transcends traditional applications. It has been employed as a noise reduction solution in urban areas, where sound pollution is a concern, and as a filtration medium in chemical processing plants, demonstrating its diverse utility. Additionally, architects have embraced it as a tool for creating dynamic building facades that harness natural light while maintaining structural integrity. In conclusion, perforated metal mesh is a material defined by its balance of robust functionality and aesthetic appeal. Its application spans multiple industries, driven by its unique combination of properties such as durability, lightweight, and adaptability. The collective expertise and historical data reinforce its position as a trustworthy and authoritative choice in the market. Advances in perforation technology and design continue to expand its possibilities, proving that perforated metal mesh is not merely a backdrop but a dynamic element shaping the future of material applications.

Trustworthiness in the realm of perforated metal mesh comes from longstanding relationships with manufacturers and suppliers known for consistent quality and innovation. Partnering with reputable providers ensures that projects meet both regulatory standards and customer expectations. Callback rates and product durability often serve as benchmarks for gauging the reliability of a supplier. Manufacturers like McNICHOLS and Wire Mesh Corporation have built their reputation over decades, fostering trust through rigorous quality controls and customer-focused service. Authoritativeness is established through a deep understanding of industry standards and historical application data. Over the years, industry specialists have compiled vast amounts of data, highlighting the performance and longevity of perforated metal mesh in various environments and applications. This data helps guide critical decision-making processes, ensuring that materials meet the specifications required in fields ranging from industrial to architectural. Real-world experiences serve as invaluable insights into the material's versatility. Case studies from successful installations reveal that the material transcends traditional applications. It has been employed as a noise reduction solution in urban areas, where sound pollution is a concern, and as a filtration medium in chemical processing plants, demonstrating its diverse utility. Additionally, architects have embraced it as a tool for creating dynamic building facades that harness natural light while maintaining structural integrity. In conclusion, perforated metal mesh is a material defined by its balance of robust functionality and aesthetic appeal. Its application spans multiple industries, driven by its unique combination of properties such as durability, lightweight, and adaptability. The collective expertise and historical data reinforce its position as a trustworthy and authoritative choice in the market. Advances in perforation technology and design continue to expand its possibilities, proving that perforated metal mesh is not merely a backdrop but a dynamic element shaping the future of material applications.

Latest news

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025