-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 11, 2024 10:25 Back to list

Quality Metal Wire Mesh Production for Diverse Industrial Applications

The Role and Importance of Metal Wire Mesh Manufacturers

Metal wire mesh is an integral component in numerous industries, serving diverse applications such as construction, agriculture, food processing, and industrial filtration. The significance of metal wire mesh manufacturers cannot be overstated; they are the backbone of this extensive market, producing high-quality products that cater to various needs.

Understanding Metal Wire Mesh

Metal wire mesh is created by weaving or welding metal wires together, forming a grid-like structure. The mesh can be constructed from a variety of materials, including stainless steel, aluminum, and galvanized steel, each chosen for its unique properties that suit specific applications. Depending on the wire diameter, spacing, and mesh type, products can range from fine filter mesh to heavy-duty structural components.

Key Applications of Metal Wire Mesh

1. Construction and Architecture One of the primary applications of metal wire mesh is in construction. It is commonly used for reinforcing concrete and masonry, enhancing structural integrity. Additionally, architectural designs often incorporate decorative wire mesh for aesthetic purposes, providing both beauty and functionality.

2. Industrial Filtration Metal wire mesh is essential in the filtration industry. It is used to create filters that separate solids from liquids or gases, ensuring the purity and quality of products in sectors such as pharmaceuticals, chemicals, and food & beverage.

3. Agriculture In agriculture, wire mesh serves as fencing material, helping to secure properties and protect crops from pests. It is also used in seed screening and soil erosion control, contributing to more sustainable agricultural practices.

4. Safety and Security Metal wire mesh is utilized in security applications, such as fencing and barriers, which safeguard properties and restrict unauthorized access. Mesh grating is also common in safety platforms and walkways, providing slip resistance and structural support.

5. Custom Applications Beyond general applications, some manufacturers specialize in producing custom wire mesh solutions tailored to specific customer requirements. This flexibility allows for innovations in design and usability across multiple industries.

The Manufacturing Process

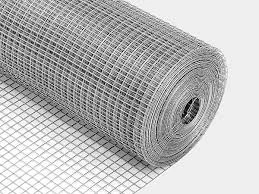

metal wire mesh manufacturer

The manufacturing of metal wire mesh involves several stages, including wire drawing, weaving or welding, and finishing. Wire drawing reduces the diameter of the metal wire, while weaving or welding forms the mesh. Depending on the intended use, the final product may undergo additional treatments, such as galvanization to improve corrosion resistance or powder coating for enhanced aesthetics.

Quality control is a vital aspect of the manufacturing process. Manufacturers employ rigorous testing methods to ensure that the wire mesh meets industry standards and client specifications. This includes checking wire diameter, mesh opening size, and overall strength, which are critical for the end user's safety and satisfaction.

Choosing the Right Manufacturer

When selecting a metal wire mesh manufacturer, several factors should be considered

1. Experience and Expertise A manufacturer with extensive industry experience is more likely to produce high-quality products. Their knowledge of materials, manufacturing processes, and market demands is invaluable.

2. Product Range A versatile manufacturer that offers a variety of mesh types, materials, and custom solutions can better meet specific needs.

3. Quality Assurance Look for manufacturers that adhere to recognized quality standards. Certifications and compliance with industry regulations are indicators of reliable product quality.

4. Customer Service Effective communication and responsive customer support are crucial for a smooth purchasing experience. A good manufacturer should be willing to assist with design, inquiries, and post-purchase support.

5. Pricing and Value While cost is always a consideration, it should not be the sole factor. Evaluate the value offered, including quality, durability, and the manufacturer’s reputation.

Conclusion

Metal wire mesh manufacturers play a crucial role in supplying a wide range of industries with essential materials. Their ability to produce durable, high-quality products tailored to various applications makes them indispensable in modern manufacturing. As technology and materials continue to evolve, manufacturers who adapt to new trends and standards will not only thrive but also contribute significantly to the success of the industries they serve. Whether you are a business seeking a reliable supplier or an individual exploring options for projects, understanding the role and importance of these manufacturers is key to making informed decisions in the world of metal wire mesh.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025