-

+86 15030157877

-

sales@galvanizedmetalmesh.com

May . 07, 2025 18:13 Back to list

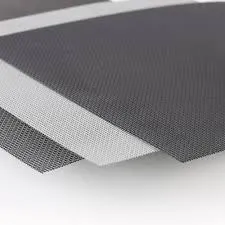

Perforated Metal Panels Supplier High-Quality & Custom Solutions

- Understanding Perforated Metal Panels: Basics and Market Data

- Technical Advantages Driving Industry Adoption

- Comparative Analysis of Leading Global Manufacturers

- Customization Strategies for Specific Project Needs

- Material Innovation and Manufacturing Standards

- Real-World Applications Across Key Industries

- Why Partner with Established Perforated Metal Panel Exporters

(perforated metal panel)

Understanding Perforated Metal Panels: Basics and Market Data

Perforated metal panels have become essential architectural and industrial components, with the global market projected to reach $6.8 billion by 2028 (Grand View Research, 2023). These precision-engineered sheets feature patterned holes that provide optimal airflow, light filtration, and structural efficiency. Leading exporters now leverage automated laser-cutting systems achieving ±0.1mm tolerance, enabling complex geometric patterns across stainless steel, aluminum, and specialty alloys.

Technical Advantages Driving Industry Adoption

Modern manufacturing processes deliver panels with:

- 93-97% open area configurations

- Custom hole diameters from 0.3mm to 120mm

- Sheet thickness capabilities: 0.5mm to 12mm

Advanced nesting software reduces material waste by 18-22% compared to traditional punching methods, while robotic quality control systems perform 360-degree surface inspections at 2 panels/second.

Comparative Analysis of Leading Global Manufacturers

| Manufacturer | Location | Annual Capacity | Minimum Hole Tolerance | Material Options |

|---|---|---|---|---|

| MetalTech Global | Germany | 850,000 m² | ±0.08mm | 9 |

| PrecisionPerf | USA | 620,000 m² | ±0.12mm | 7 |

| AsiaCore Metals | China | 1.2M m² | ±0.15mm | 12 |

Customization Strategies for Specific Project Needs

Top suppliers now offer:

- 3D modeling integration with BIM software

- Prototype production within 72 hours

- Dual-certification materials (ISO 9001 and ASTM)

Architectural projects increasingly demand curved panels with radius bending down to 150mm, achievable through CNC-controlled hydraulic presses.

Material Innovation and Manufacturing Standards

Recent advancements include:

- Antimicrobial copper alloys for healthcare

- Solar-reflective coatings reducing heat gain by 40%

- Recycled-content aluminum with 85% post-industrial waste

Leading manufacturers maintain Class 1 fire ratings (BS 476) and 25-year corrosion warranties for exterior applications.

Real-World Applications Across Key Industries

Case studies demonstrate:

- 45% energy reduction in HVAC systems using optimized airflow panels

- 30% weight savings in transportation equipment

- 78% faster installation times for acoustic ceiling systems

Why Partner with Established Perforated Metal Panel Exporters

Certified suppliers provide technical support throughout the project lifecycle, from material selection to installation guidance. Global logistics networks ensure lead times under 21 days for standard orders, with container-load optimization reducing shipping costs by 15-18%. Quality assurance programs typically include third-party inspections and digital documentation for traceability.

(perforated metal panel)

FAQS on perforated metal panel

Q: What materials are commonly used for perforated metal panels?

A: Perforated metal panels are typically made from stainless steel, aluminum, galvanized steel, or copper. These materials offer durability, corrosion resistance, and versatility for architectural and industrial applications. The choice depends on project requirements like environment and aesthetics.

Q: Can perforated metal panel manufacturers customize hole patterns?

A: Yes, reputable manufacturers offer custom hole patterns, sizes, and shapes to meet specific design or functional needs. Advanced laser-cutting technology ensures precision and consistency. Clients can request samples or CAD designs for approval.

Q: How do perforated metal panel suppliers ensure quality control?

A: Suppliers implement strict quality checks, including material testing, hole accuracy verification, and surface finish inspections. Certifications like ISO 9001 often reflect adherence to industry standards. Third-party audits may also be conducted for large orders.

Q: What industries benefit from perforated metal panel exporters?

A: Exporters serve industries like construction (facades, sunscreens), automotive (grilles, filters), HVAC (ventilation), and acoustics (soundproofing). Their panels are also used in agriculture, mining, and interior design for functional or decorative purposes.

Q: How long does it take for perforated metal panel suppliers to fulfill orders?

A: Lead times vary based on order size, material availability, and customization. Standard orders may take 2-4 weeks, while complex designs could require 6-8 weeks. Exporters often provide timelines upfront to align with project schedules.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025