-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 03, 2024 03:02 Back to list

Leading Manufacturer of High-Quality Perforated Iron Sheets for Various Applications

The Role and Importance of Perforated Iron Sheet Manufacturers

Perforated iron sheets have become increasingly essential in various industries due to their unique properties and applications. As a fundamental element in construction, architecture, filtration, and even electronics, these sheets are manufactured by specialized companies that focus on precision engineering and high-quality standards. Understanding the role of perforated iron sheet manufacturers can illuminate their significance in a diverse range of sectors.

What are Perforated Iron Sheets?

Perforated iron sheets are metal plates with a series of holes or openings punched through them. These holes can vary in shape, size, and pattern, depending on the intended use of the sheet. The process of perforation not only reduces the weight of the material but also enhances its strength and flexibility. Manufacturers typically use iron or steel because of their durability and resistance to wear and tear, making them suitable for both indoor and outdoor applications.

Key Applications of Perforated Iron Sheets

1. Architectural Design One of the most visually striking uses of perforated iron sheets is in architectural design. They can be employed in facades, sunscreens, and decorative panels, providing aesthetics while allowing natural light and ventilation. Architects appreciate their versatility, as well as the endless design possibilities offered by different hole patterns.

2. Industrial Uses In industrial settings, perforated iron sheets are crucial for safety and efficiency. They are commonly used as grates and filters, allowing liquids and fine particles to pass through while retaining larger debris. This makes them invaluable in filtration systems for water treatment plants, chemical processing, and food and beverage manufacturing.

3. Furniture and Interior Design The trend of incorporating industrial elements into furniture design has increased the demand for perforated iron sheets in creating stylish interiors. Tables, shelving units, and even lighting fixtures often feature these sheets, combining functionality with modern style.

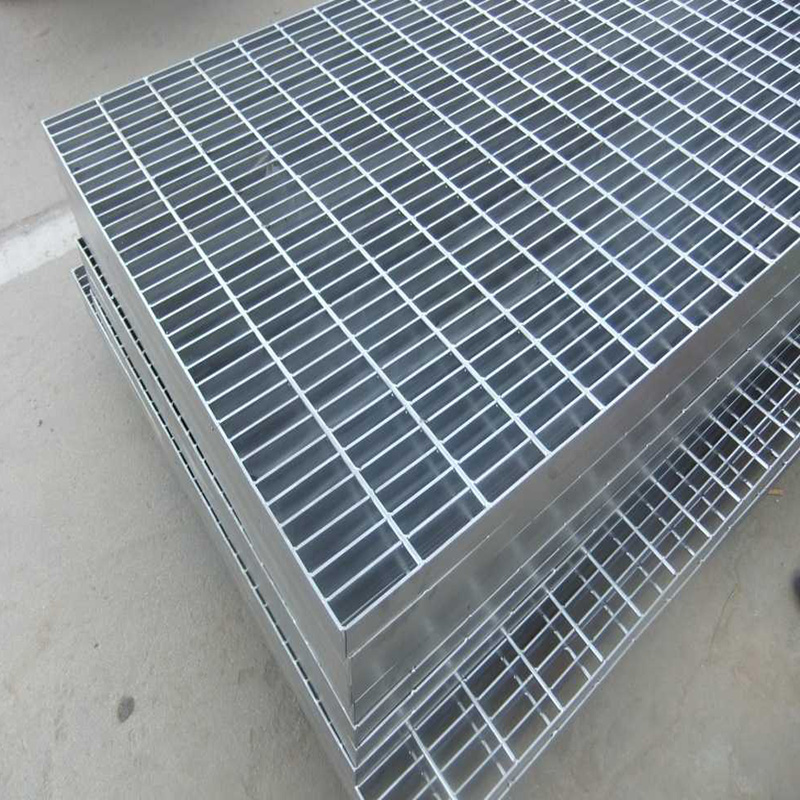

perforated iron sheet manufacturer

4. Acoustic Management Due to their ability to absorb sound, perforated iron sheets have found applications in soundproofing and acoustic management systems. They can be utilized in concert halls, recording studios, and open-plan offices to control noise levels effectively.

The Manufacturing Process

The manufacturing of perforated iron sheets involves multiple steps that emphasize precision and quality. Initially, the iron sheets are cut to the desired size. Following this, a perforation process is executed, where advanced machinery punches holes into the sheets. The spacing, size, and arrangement of holes are tailored according to the specific requirements of the customer's order.

Quality control is a critical aspect of the manufacturing process. Reputable manufacturers test their products for durability, corrosion resistance, and structural integrity to ensure they meet industry standards. Many manufacturers also offer additional services, such as finishing, coating, or custom designs, to cater to specific customer needs.

The Future of Perforated Iron Sheet Manufacturing

As industries continue to evolve, the demand for customized and efficient materials will likely increase. Perforated iron sheet manufacturers are expected to innovate their processes and products to meet new challenges and trends, such as sustainability and energy efficiency. Eco-friendly materials and production methods may become more prevalent as the construction and manufacturing industries strive to reduce their environmental impact.

In conclusion, perforated iron sheet manufacturers play a vital role across various sectors, providing essential materials that enhance functionality and aesthetic appeal. As technology advances and industries evolve, these manufacturers will continue to innovate, maintaining their importance in the global market.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025