-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 16, 2024 03:57 Back to list

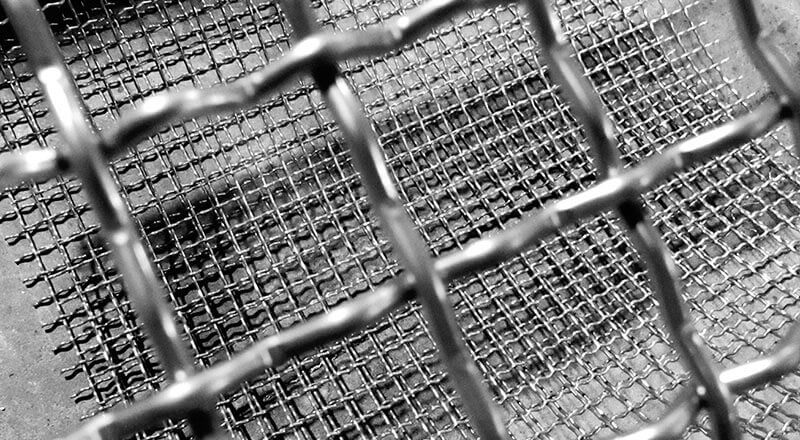

perforated metal mesh sheet factories

Exploring Perforated Metal Mesh Sheet Factories

In today's manufacturing landscape, perforated metal mesh sheets have emerged as essential components in a wide array of industries, including construction, aerospace, automotive, and more. As a versatile material, these sheets offer functionality, aesthetic appeal, and structural integrity, making them a popular choice for architects, designers, and engineers alike. This article delves into the intricacies of perforated metal mesh sheet factories, their manufacturing processes, applications, and the future of this indispensable material.

What Are Perforated Metal Mesh Sheets?

Perforated metal mesh sheets are materials created by puncturing holes in a solid metal sheet using specialized machinery. The size, shape, and spacing of the holes can be customized to meet specific design requirements. Commonly used metals include stainless steel, aluminum, and mild steel, each offering unique properties that cater to different applications. These sheets can be used for various purposes, such as filtration, ventilation, decoration, and support structures.

The Manufacturing Process

The production of perforated metal mesh sheets begins with the selection of a base metal, which is then fed into a perforating machine. This machine employs a combination of mechanical pressure and precise tooling to create a pattern of holes in the metal. The process can be performed through various methods, including a continuous operation for large rolls or a discrete method for individual sheets.

Once the sheets are perforated, they undergo a series of finishing processes. These processes may involve cleaning, deburring, and coating to enhance corrosion resistance and improve appearance. Factories often leverage advanced technologies such as laser cutting for precision shaping and CNC machining for creating custom designs, enabling them to meet diverse customer needs efficiently.

Applications of Perforated Metal Mesh Sheets

The versatility of perforated metal mesh sheets allows them to be utilized in numerous applications across various sectors. In construction, they are often used for exterior facades and sunshades, providing a modern aesthetic while allowing light and ventilation. In the automotive industry, perforated sheets are employed in sound insulation and cooling systems.

perforated metal mesh sheet factories

In the field of filtration, these sheets are vital. They are used in various filtration systems, including water treatment plants and air filtration systems, because their precise hole sizes can effectively separate particles from liquids and gases. Additionally, they are a key element in designing decorative elements, such as wall art and furniture, enhancing both function and style.

The Role of Factories in Sustainability

As global industries increasingly focus on sustainability, perforated metal mesh sheet factories are adapting their practices to minimize waste and energy consumption. Some manufacturers are investing in eco-friendly production processes and recycling waste materials. Additionally, the durability and recyclability of metals make perforated sheets an environmentally responsive choice.

The Future of Perforated Metal Mesh Sheets

Looking ahead, the demand for perforated metal mesh sheets is expected to grow due to their wide-ranging applications and increasing preference for sustainable materials. Technological advancements in manufacturing processes, including automation and smart manufacturing techniques, will lead to enhanced efficiency, precision, and reduced costs.

Moreover, the integration of digital design tools and 3D modeling in the design phase allows for unprecedented customization and innovation, giving architects and engineers the freedom to create more complex designs that were previously difficult to achieve.

Conclusion

Perforated metal mesh sheet factories are at the forefront of innovation, producing products that meet the diverse needs of modern industries. As they continue to evolve in response to technological advancements and sustainability imperatives, these factories are poised to play a crucial role in shaping the future of construction, engineering, and design. The enduring versatility and functionality of perforated metal mesh sheets ensure their importance will remain significant, making them integral to diverse applications across the globe.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025