-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 03, 2024 07:40 Back to list

perforated metal panel factory

The Rise of Perforated Metal Panel Factories Innovations and Applications

In recent years, the manufacturing industry has witnessed a significant transformation with the increasing popularity of perforated metal panels. These versatile materials are being utilized in various sectors, from architecture to industrial applications. Their unique characteristics, such as durability, aesthetic appeal, and adaptability, have led to a surge in demand for perforated metal panel factories.

The Rise of Perforated Metal Panel Factories Innovations and Applications

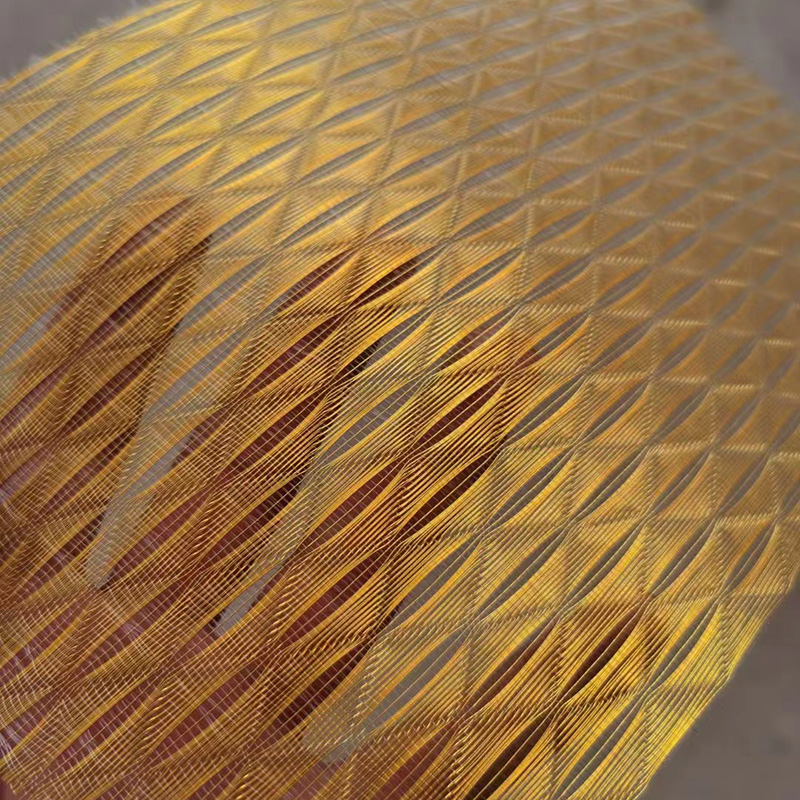

One of the key advantages of perforated metal panels is their aesthetic versatility. In architecture, they are often used in facades, ceilings, and interior partitions to create visually striking designs. These panels can enhance the look of a building while providing additional benefits like light control and ventilation. For instance, a modern office building may feature perforated metal screens that not only contribute to its overall design but also reduce glare and heat from incoming sunlight.

perforated metal panel factory

Furthermore, perforated metal panels are gaining traction in the field of acoustics. Their ability to absorb sound is utilized in concert halls, theaters, and offices where noise control is essential. Factories specializing in acoustic perforated panels are emerging, focusing on engineering materials that effectively balance aesthetics with functionality.

In industrial settings, perforated metal panels serve numerous purposes, such as filtration and protection. They are commonly employed in machinery guards, storage units, and safety barriers. The sturdy nature of metal combined with the customizable hole patterns allows for efficient airflow, cooling, and debris management, ultimately enhancing operational efficiency. Factories producing these panels are increasingly focused on using high-quality materials that withstand harsh conditions, ensuring longevity and reliability.

As sustainability becomes a key focus for many industries, perforated metal panels are also finding favor due to their eco-friendly characteristics. Manufacturers are increasingly choosing recyclable materials and employing sustainable production processes. This not only meets environmental standards but also appeals to consumers who are conscious about their ecological footprint. Factories are integrating lean manufacturing techniques to minimize waste and optimize resource utilization, ensuring that their operations are as green as possible.

Looking towards the future, the growth of perforated metal panel factories appears poised to continue. With advancements in production technology, such as automation and 3D printing, the capabilities for designing and producing perforated panels will expand significantly. As industries evolve and new applications are discovered, these factories will play a crucial role in meeting the ever-changing demands of the market. In summary, perforated metal panels are reshaping various sectors, with dedicated factories at the forefront of this innovation. Their unparalleled blend of functionality and aesthetics continues to offer solutions that enhance both form and function across multiple industries.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025