-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 06, 2024 13:48 Back to list

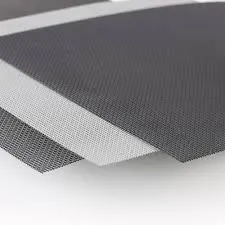

perforated metal sheet

Exploring Perforated Metal Sheets Versatility and Applications

Perforated metal sheets are increasingly gaining popularity in various industries due to their unique properties and versatile applications. These sheets, created by punching holes into metal, offer an array of benefits that make them indispensable in contemporary design and manufacturing. This article delves into the characteristics of perforated metal sheets, their production process, and their diverse applications in different sectors.

Understanding Perforated Metal Sheets

Perforated metal sheets are made from various metals, including steel, aluminum, copper, and brass. The perforation process involves using a punch press to create a series of holes in the metal sheet, which can vary in size, shape, and arrangement. The design possibilities are extensive, allowing for bespoke solutions tailored to specific requirements. The spacing and pattern of holes can be customized, contributing to both functional and aesthetic applications.

The strength and durability of the base material, combined with the reduction in weight due to perforation, make these sheets an attractive option for many uses. Furthermore, the open structure allows for the passage of air, light, and sound, making them suitable for a range of functional applications.

Production Process

The production of perforated metal sheets typically involves several steps. First, a high-quality metal sheet is selected based on the intended application. Next, specialized equipment, such as CNC (Computer Numerical Control) punching machines, is used to create precise holes in the chosen pattern. Advanced technology allows manufacturers to achieve intricate designs that can enhance aesthetic appeal while maintaining structural integrity.

perforated metal sheet

After the perforation process, the sheets can undergo additional treatments. These may include galvanization to prevent corrosion, powder coating for color and finish, or polishing for aesthetic purposes. These finishing processes not only enhance the appearance of the metal sheets but also elevate their performance in various environments.

Applications Across Industries

The applications of perforated metal sheets are vast and varied. One of the most common uses is in architectural design, where they provide an innovative solution for facades, ceilings, and interior spaces. Designers often utilize perforated metal to create striking visual effects, engage with light and shadow, and enhance acoustic properties in large spaces such as auditoriums and sports arenas.

In the industrial sector, perforated metal sheets are used for filtering and separation processes. Their ability to allow for airflow while providing strength makes them ideal for applications like ventilation systems, dust control equipment, and noise reduction panels. In the food processing industry, perforated sheets are employed in equipment such as sieves and trays to facilitate drying and cooking while ensuring hygiene standards.

Additionally, the automotive and aerospace industries frequently use these sheets for lightweight structural components, which help improve fuel efficiency without sacrificing strength or safety. Similarly, in the furniture industry, perforated metal can be found in chairs, tables, and decorative elements that balance functionality with modern aesthetics.

Conclusion

In conclusion, perforated metal sheets are versatile materials with a broad range of applications across multiple industries. Their unique properties allow for an innovative approach to design, which can enhance functionality while ensuring aesthetic appeal. As technology continues to advance, the possibilities for customization and application will likely expand, making perforated metal sheets an enduring choice for engineers, architects, and designers alike. Whether in architecture, industrial applications, or furniture design, perforated metal provides an exciting solution that combines form and function seamlessly.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025