-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 30, 2024 01:32 Back to list

Top Suppliers of Perforated Panels for Various Applications and Industries

The Rise of Perforated Panel Manufacturers Innovation and Sustainability

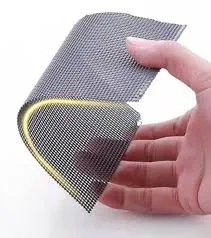

In recent years, the demand for perforated panels has seen a significant surge, driven by their versatility and aesthetic appeal in various industries. Perforated panels, characterized by a series of holes or slots, offer both functional and decorative benefits, making them a preferred choice in architecture, acoustics, and even industrial applications. This article explores the role and importance of perforated panel manufacturers in today’s market.

One of the primary applications of perforated panels is in building construction and design. Architects increasingly incorporate these panels for aesthetic purposes, enabling creative designs that allow light and airflow while reducing material weight. The ability to customize hole patterns, sizes, and finishes gives designers the freedom to tailor solutions to meet specific project needs. This flexibility not only enhances the visual appeal of buildings but also contributes to energy efficiency, as perforated panels can be strategically placed to minimize heat gain and loss.

Acoustic performance is another key factor driving the popularity of perforated panels. In environments where sound control is critical, such as theaters, offices, and open spaces, these panels can be designed to absorb sound effectively. Manufacturers specialize in producing panels that meet specific acoustic criteria, helping to create comfortable and productive environments. The combination of aesthetic design and sound absorption makes perforated panels an ideal solution for modern architectural challenges.

perforated panel manufacturers

Sustainability is also a significant consideration for many perforated panel manufacturers today. With an increasing focus on environmentally friendly building materials, many companies are adopting sustainable practices, such as using recycled materials and implementing energy-efficient production processes. By sourcing materials responsibly and minimizing waste during manufacturing, these companies not only meet regulatory standards but also respond to consumer demand for greener options.

Moreover, the technological advancements in manufacturing processes have made it easier for companies to innovate and improve the quality of perforated panels. CNC (Computer Numerical Control) technology, laser cutting, and advanced powder coating techniques allow manufacturers to produce highly precise and durable products. These innovations lead to better performance, lower maintenance costs, and an extended lifespan of the panels, thereby adding value to architectural projects.

In conclusion, perforated panel manufacturers play a crucial role in various industries by providing innovative solutions that blend functionality with aesthetics. Their commitment to quality, sustainability, and design innovation ensures that perforated panels remain a sought-after choice for architects and builders alike. As the market continues to evolve, these manufacturers will undoubtedly contribute to shaping the future of construction and design with their versatile offerings.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025