-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 31, 2024 13:54 Back to list

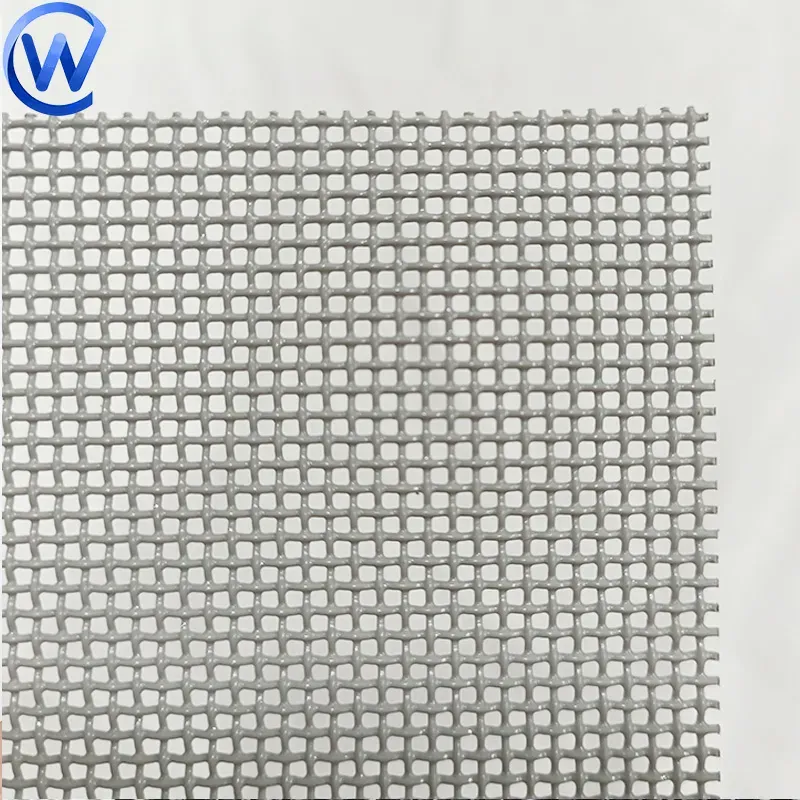

perforated sheet metal

Understanding Perforated Sheet Metal Versatility and Applications

Perforated sheet metal is a highly versatile material used across various industries, showcasing a unique combination of functionality and aesthetic appeal. Characterized by a series of holes or openings that are uniformly distributed throughout the sheet, perforated metal can be made from various materials including steel, aluminum, brass, and plastic. This article explores the manufacturing process, benefits, and diverse applications of perforated sheet metal.

Manufacturing Process

The manufacturing of perforated sheet metal typically involves a two-step procedure punching and finishing. During the punching phase, a specialized machine, often known as a punch press, creates holes in the sheet metal according to specific designs or patterns. The size, shape, and spacing of these holes can vary significantly, allowing for customization that meets particular project specifications.

After the punching process, the perforated sheets undergo a finishing treatment which may include cleaning, coating, or bending. The finishing process enhances durability, protects against corrosion, and can improve aesthetics. Common finishes include anodizing for aluminum, galvanizing for steel, and powder coating, which provides a variety of color options.

Benefits of Perforated Sheet Metal

The advantages of using perforated sheet metal are vast. Firstly, its ability to allow air, light, and sound to pass through makes it an ideal choice for applications requiring filtration, ventilation, or shading. The openness of the sheet also helps reduce weight compared to solid metal, making it easier to handle and transport.

Another significant benefit is its aesthetic versatility. The patterns created through perforation can enhance the visual appeal of a product or architectural element. Companies and designers often utilize various hole shapes—such as round, square, or decorative designs—to create unique appearances in their projects.

perforated sheet metal

Furthermore, perforated sheet metal is known for its durability and strength. Depending on the type of metal used and its thickness, perforated sheets can withstand harsh environments, making them suitable for both indoor and outdoor applications. This resilience, combined with low maintenance requirements, makes perforated metal a cost-effective long-term solution.

Applications of Perforated Sheet Metal

Perforated sheet metal finds applications in a plethora of fields, reflecting its versatility. In the construction industry, it serves numerous roles, from cladding and sunshades to ceiling tiles and partition walls. Architects frequently incorporate perforated sheets into their designs to achieve both functionality and aesthetic value. The ability to create light and shadow effects while maintaining visual openness is particularly appealing.

In the manufacturing sector, perforated metal is often used in filtration systems to separate solids from liquids or gases. Its ability to accommodate varying hole sizes allows for effective fluid management, making it indispensable in industries such as food processing, water treatment, and chemical production.

Another common application is in the production of furniture and commercial fixtures. Perforated sheet metal is used in items such as shelving units, decorative screens, and even auditory panels for improved sound quality in public spaces. Its blend of aesthetic quality and structural integrity makes it an attractive option for designers and manufacturers alike.

In the automotive and aerospace industries, perforated sheet metal contributes to weight reduction while maintaining strength and performance standards. Components such as radiator grills and interior paneling frequently utilize perforated metal to meet these demands.

Conclusion

Perforated sheet metal is a fundamental material with extensive applications across various industries. Its unique structure allows for both functional and decorative uses, while the manufacturing process ensures customization to meet specific needs. The benefits of reduced weight, improved airflow, and aesthetic appeal make perforated sheet metal a preferred choice for architects, manufacturers, and designers alike. As industries continue to evolve, the demand for innovative and versatile materials like perforated sheet metal will undoubtedly grow, securing its place as an essential component in modern design and engineering.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025