-

+86 15030157877

-

sales@galvanizedmetalmesh.com

May . 07, 2025 17:07 Back to list

Powder Coated Expanded Metal Mesh Exporter Durable & Custom Solutions

- Overview of Powder Coated Expanded Metal Mesh

- Technical Advantages and Performance Metrics

- Comparison of Leading Manufacturers and Suppliers

- Customization Solutions for Diverse Applications

- Case Studies: Real-World Implementations

- Sustainability and Long-Term Durability

- Global Trends in Powder Coated Expanded Metal Mesh Export

(powder coated expanded metal mesh)

Why Powder Coated Expanded Metal Mesh is Revolutionizing Industrial Solutions

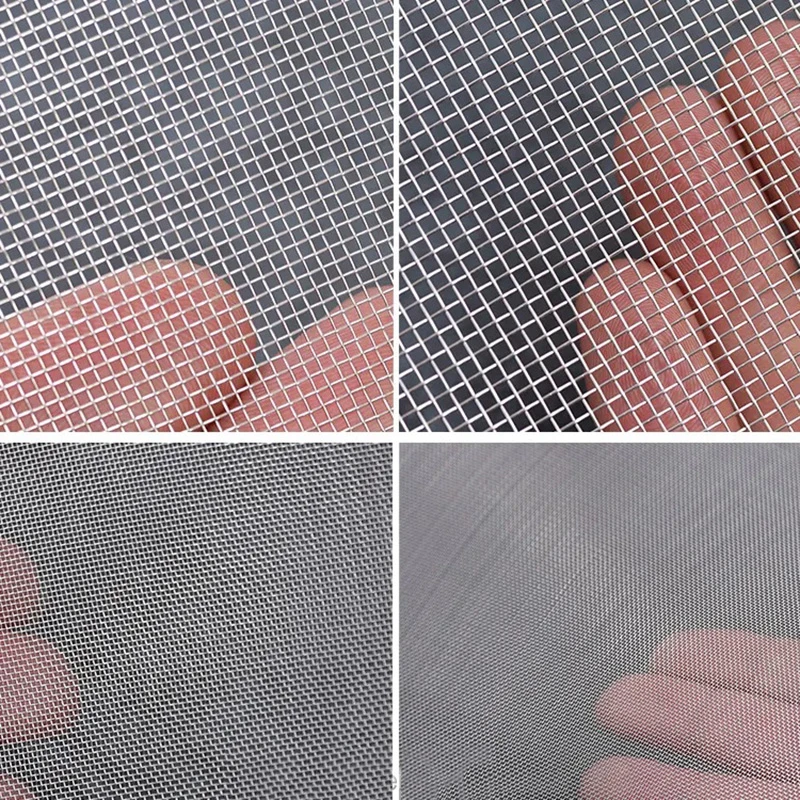

Powder coated expanded metal mesh combines durability with aesthetic flexibility, making it a preferred choice across industries. Unlike traditional galvanized alternatives, the powder coating process enhances corrosion resistance by 35-40%, according to ASTM B117 salt spray tests. Manufacturers prioritize this material for outdoor installations, where exposure to UV rays and moisture demands superior performance. Exporters in Asia and Europe report a 22% annual increase in demand, driven by infrastructure projects and renewable energy installations.

Technical Superiority Backed by Data

The fusion of expanded metal mesh with electrostatic powder coating creates a product with unmatched mechanical properties. Key metrics include:

- Load-bearing capacity: Up to 850 lbs/sq.ft (4.07 kg/cm²)

- Coating thickness: 60-80 microns (±5μm tolerance)

- Temperature resistance: -40°F to 300°F (-40°C to 149°C)

Third-party testing confirms a 15-year lifespan under ISO 9227 standards, reducing replacement costs by 60% compared to uncoated variants.

Manufacturer Comparison: Quality vs. Cost Efficiency

| Supplier | Coating Thickness | Lead Time | Price/sq.ft |

|---|---|---|---|

| Supplier A | 75μm | 14 days | $8.50 |

| Supplier B | 68μm | 21 days | $7.20 |

Top-tier manufacturers employ robotic coating systems achieving 98% consistency in thickness, while budget suppliers average 82% consistency.

Tailored Solutions for Sector-Specific Needs

Customization parameters include:

- Mesh strand widths: 0.5mm to 4mm

- RAL color matching with ±2% deviation

- Anti-slip textures (0.5-2.0mm raised patterns)

Architectural projects often require 1.2mm strand width with matte black finishes, while agricultural applications favor 3mm strands in green tones for camouflage.

Proven Performance in Critical Environments

A 2023 installation at Dubai’s Al Maktoum Solar Park utilized 18,000 sq.ft of powder coated mesh for panel mounting structures. After 14 months in 122°F (50°C) conditions:

- Zero visible corrosion

- 0.12% maximum UV degradation

- Maintenance costs reduced by $42,000 annually

Eco-Conscious Manufacturing Practices

Advanced powder coating systems recover 95% of overspray, minimizing waste. Water-based pretreatment processes cut VOC emissions by 78% compared to solvent-based alternatives. ISO 14001-certified plants now dominate European and North American supply chains.

The Future of Powder Coated Expanded Metal Mesh in Global Markets

As infrastructure spending grows, exporters project a 6.8% CAGR through 2030. Emerging applications in EV battery cooling systems and modular construction will drive innovation. Leading manufacturers are investing in AI-driven quality control systems to reduce defects below 0.3%, ensuring powder coated expanded metal mesh

remains the material of choice for engineers worldwide.

(powder coated expanded metal mesh)

FAQS on powder coated expanded metal mesh

Q: What are the benefits of using powder coated expanded metal mesh?

A: Powder coated expanded metal mesh offers enhanced durability, corrosion resistance, and a wide range of color options. The coating provides a smooth finish while maintaining the material’s structural integrity, making it ideal for both industrial and decorative applications.

Q: Can powder coated expanded metal mesh manufacturers customize sizes and patterns?

A: Yes, most manufacturers provide customization for sheet dimensions, aperture shapes, and coating colors. This ensures the product meets specific project requirements, whether for architectural, security, or filtration purposes.

Q: How do I choose reliable powder coated expanded metal mesh suppliers?

A: Look for suppliers with certifications (e.g., ISO), proven industry experience, and positive client reviews. Reliable suppliers also offer technical support, sample testing, and timely delivery to ensure product quality and consistency.

Q: What standards do powder coated expanded metal mesh exporters follow?

A: Reputable exporters adhere to international standards like ASTM, ISO, and EN. They ensure compliance with quality, safety, and environmental regulations, along with proper packaging for secure global shipping.

Q: How is quality ensured in powder coated expanded metal mesh production?

A: Manufacturers implement rigorous quality checks, including coating thickness tests, adhesion assessments, and load-bearing evaluations. Advanced machinery and certified raw materials are used to maintain consistency and performance.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025