-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jun . 13, 2024 15:56 Back to list

Producer of perforated metal sheets

The Art and Function of Perforated Metal Sheets A Manufacturer's Perspective

Perforated metal sheets, a versatile and innovative material, have been a staple in various industries for decades. As a leading manufacturer in this domain, we understand the intricacies and potential of these seemingly simple yet highly adaptable products. Our commitment to precision, quality, and innovation has positioned us at the forefront of the perforated metal sheet manufacturing industry.

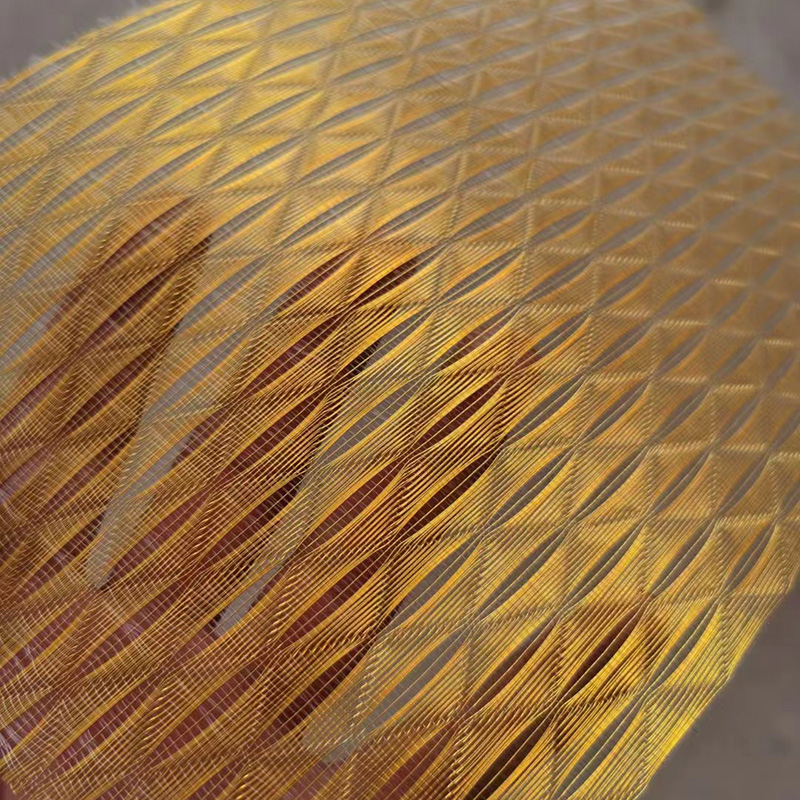

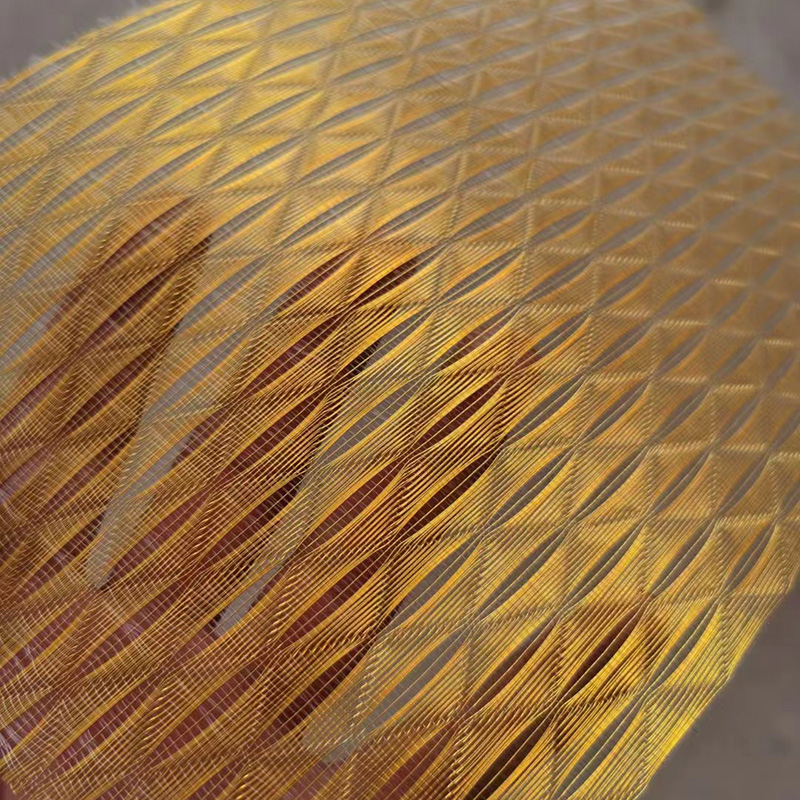

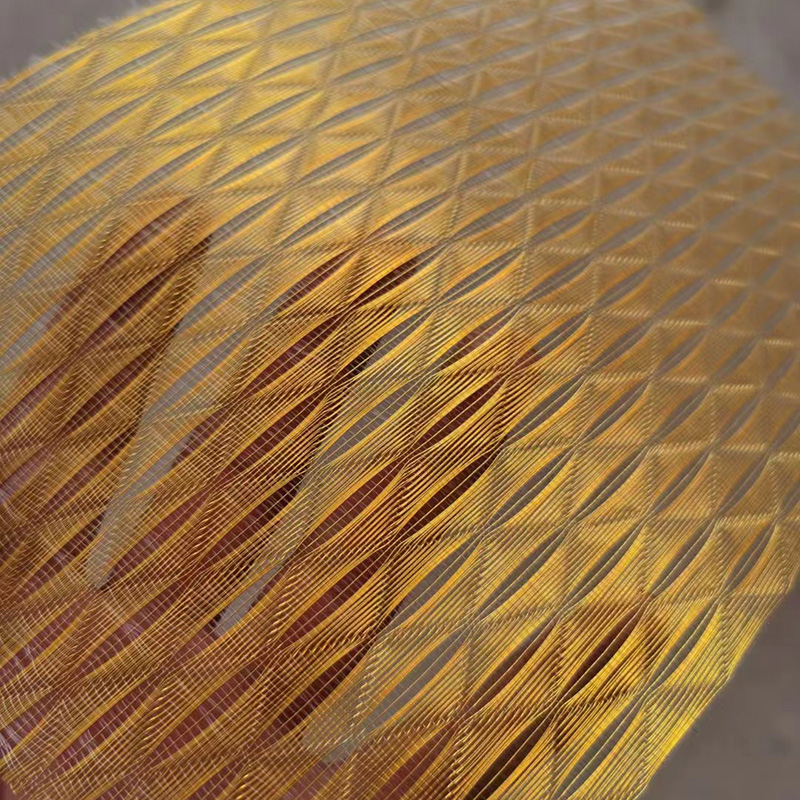

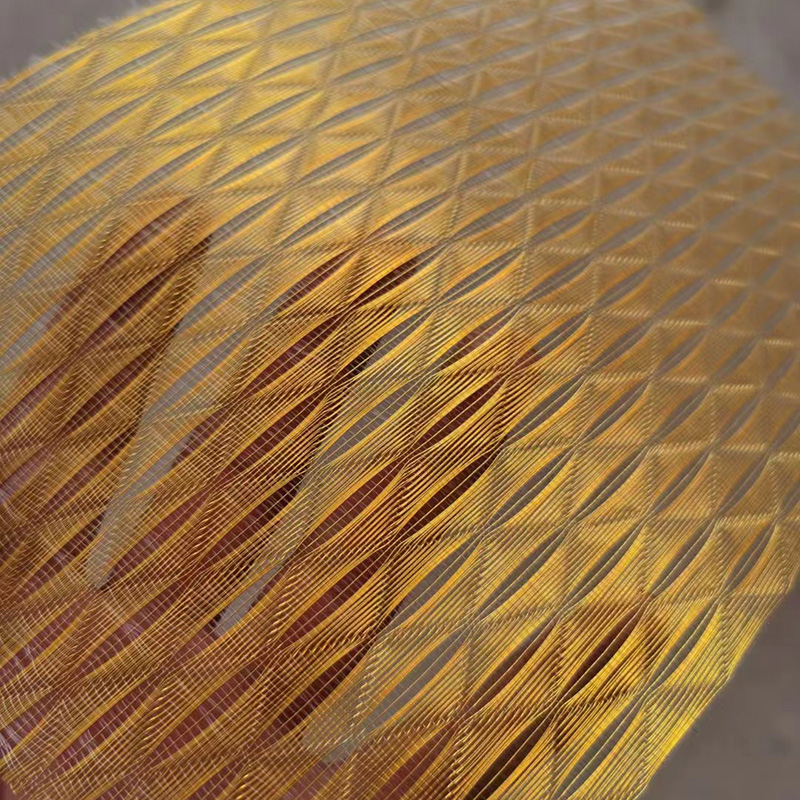

Perforated metal sheets are created through a process that involves punching or piercing a pattern into a flat metal sheet. The result is a unique blend of aesthetics and functionality, making them ideal for applications ranging from architectural design to industrial filtration systems. The percentage of perforation, or perforated%, is a critical factor, determining the sheet's properties such as air flow, light transmission, and strength.

Our manufacturing process begins with selecting the right raw materials. We work with an array of metals, including steel, aluminum, stainless steel, and copper, each offering distinct advantages depending on the application. The choice of metal, its thickness, and the perforation pattern are all meticulously decided based on the end-use requirements.

The perforation process itself is a blend of technology and craftsmanship. High-tech machinery punches holes according to a pre-programmed pattern, ensuring consistency and accuracy. However, it's the human touch that brings uniqueness to our products, with our skilled technicians overseeing the process and making necessary adjustments to achieve the perfect balance between form and function.

The perforated metal sheet's versatility lies in its customizable nature

The perforated metal sheet's versatility lies in its customizable nature The perforated metal sheet's versatility lies in its customizable nature

The perforated metal sheet's versatility lies in its customizable nature

The perforated metal sheet's versatility lies in its customizable nature

The perforated metal sheet's versatility lies in its customizable nature perforated metal sheet manufacturer. From small, intricate patterns to large, bold designs, we can manufacture sheets with varying hole sizes, shapes, and spacing. This allows us to cater to diverse needs, whether it's for aesthetic appeal in architectural facades or practicality in acoustic panels or sieving equipment.

Beyond manufacturing, we emphasize sustainability. We strive to minimize waste during production and often recycle unused materials. Moreover, perforated metal sheets have a long lifespan and can be recycled at the end of their service life, contributing to a circular economy.

As a responsible manufacturer, we also prioritize safety and quality. Our perforated metal sheets undergo rigorous quality checks to ensure they meet international standards and customer specifications. We believe that delivering a product of exceptional quality is not just a business practice but a responsibility towards our clients and the environment.

In conclusion, perforated metal sheets are more than just a material; they are a testament to the intersection of design, functionality, and sustainability. As a manufacturer, we are proud to play a role in bringing this versatile material to life, constantly pushing the boundaries of what's possible with perforated metal sheets. Whether it's enhancing the aesthetic appeal of a building or optimizing industrial processes, we remain dedicated to crafting solutions that truly make a difference.

perforated metal sheet manufacturer. From small, intricate patterns to large, bold designs, we can manufacture sheets with varying hole sizes, shapes, and spacing. This allows us to cater to diverse needs, whether it's for aesthetic appeal in architectural facades or practicality in acoustic panels or sieving equipment.

Beyond manufacturing, we emphasize sustainability. We strive to minimize waste during production and often recycle unused materials. Moreover, perforated metal sheets have a long lifespan and can be recycled at the end of their service life, contributing to a circular economy.

As a responsible manufacturer, we also prioritize safety and quality. Our perforated metal sheets undergo rigorous quality checks to ensure they meet international standards and customer specifications. We believe that delivering a product of exceptional quality is not just a business practice but a responsibility towards our clients and the environment.

In conclusion, perforated metal sheets are more than just a material; they are a testament to the intersection of design, functionality, and sustainability. As a manufacturer, we are proud to play a role in bringing this versatile material to life, constantly pushing the boundaries of what's possible with perforated metal sheets. Whether it's enhancing the aesthetic appeal of a building or optimizing industrial processes, we remain dedicated to crafting solutions that truly make a difference.

The perforated metal sheet's versatility lies in its customizable nature

The perforated metal sheet's versatility lies in its customizable nature

The perforated metal sheet's versatility lies in its customizable nature

The perforated metal sheet's versatility lies in its customizable nature perforated metal sheet manufacturer. From small, intricate patterns to large, bold designs, we can manufacture sheets with varying hole sizes, shapes, and spacing. This allows us to cater to diverse needs, whether it's for aesthetic appeal in architectural facades or practicality in acoustic panels or sieving equipment.

Beyond manufacturing, we emphasize sustainability. We strive to minimize waste during production and often recycle unused materials. Moreover, perforated metal sheets have a long lifespan and can be recycled at the end of their service life, contributing to a circular economy.

As a responsible manufacturer, we also prioritize safety and quality. Our perforated metal sheets undergo rigorous quality checks to ensure they meet international standards and customer specifications. We believe that delivering a product of exceptional quality is not just a business practice but a responsibility towards our clients and the environment.

In conclusion, perforated metal sheets are more than just a material; they are a testament to the intersection of design, functionality, and sustainability. As a manufacturer, we are proud to play a role in bringing this versatile material to life, constantly pushing the boundaries of what's possible with perforated metal sheets. Whether it's enhancing the aesthetic appeal of a building or optimizing industrial processes, we remain dedicated to crafting solutions that truly make a difference.

perforated metal sheet manufacturer. From small, intricate patterns to large, bold designs, we can manufacture sheets with varying hole sizes, shapes, and spacing. This allows us to cater to diverse needs, whether it's for aesthetic appeal in architectural facades or practicality in acoustic panels or sieving equipment.

Beyond manufacturing, we emphasize sustainability. We strive to minimize waste during production and often recycle unused materials. Moreover, perforated metal sheets have a long lifespan and can be recycled at the end of their service life, contributing to a circular economy.

As a responsible manufacturer, we also prioritize safety and quality. Our perforated metal sheets undergo rigorous quality checks to ensure they meet international standards and customer specifications. We believe that delivering a product of exceptional quality is not just a business practice but a responsibility towards our clients and the environment.

In conclusion, perforated metal sheets are more than just a material; they are a testament to the intersection of design, functionality, and sustainability. As a manufacturer, we are proud to play a role in bringing this versatile material to life, constantly pushing the boundaries of what's possible with perforated metal sheets. Whether it's enhancing the aesthetic appeal of a building or optimizing industrial processes, we remain dedicated to crafting solutions that truly make a difference. Latest news

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025