-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 10, 2024 05:08 Back to list

PVC Coated Welded Wire Mesh Manufacturing and Supply Solutions

The Benefits of PVC Coated Welded Mesh A Look at Manufacturing Processes

In today's industrial landscape, the demand for durable and versatile fencing solutions has led to the widespread use of welded mesh products. Among these, PVC coated welded mesh is rapidly gaining popularity due to its superior performance and aesthetic appeal. In this article, we will explore the advantages of PVC coated welded mesh, the manufacturing process involved in its production, and the role of factories specializing in this innovative product.

Understanding PVC Coated Welded Mesh

PVC coated welded mesh is created by first manufacturing a grid from high-quality steel wires. These wires are welded together at intersections, creating a strong and rigid framework. The key feature of this type of mesh is the application of a layer of polyvinyl chloride (PVC), which is extruded or painted over the welded steel structure. This coating offers multiple advantages, making the mesh suitable for various applications, including security fencing, animal enclosures, and decorative purposes.

Advantages of PVC Coated Welded Mesh

1. Corrosion Resistance One of the most significant benefits of PVC coated welded mesh is its resistance to rust and corrosion. The PVC coating acts as a barrier against moisture, chemicals, and pollutants, extending the lifespan of the mesh considerably compared to untreated steel options.

2. Durability The robust nature of welded steel combined with the protective PVC layer ensures that the mesh can withstand harsh environmental conditions. This durability makes it ideal for both indoor and outdoor applications.

3. Aesthetic Appeal PVC coatings are available in various colors, allowing customization to suit different design preferences or to blend seamlessly into the surrounding environment. This feature makes PVC coated welded mesh a favored choice for residential, commercial, and agricultural uses.

4. Low Maintenance The smooth surface of PVC coated mesh makes it easy to clean, requiring minimal maintenance over the years. Unlike traditional steel fencing, which may need regular painting or treatment, PVC coated options provide a hassle-free experience.

5. Safety and Security The strong, welded framework of the mesh ensures that it is difficult to penetrate, providing an added layer of security for properties. This feature is particularly important in settings where safety is a priority, such as schools, parks, and industrial sites.

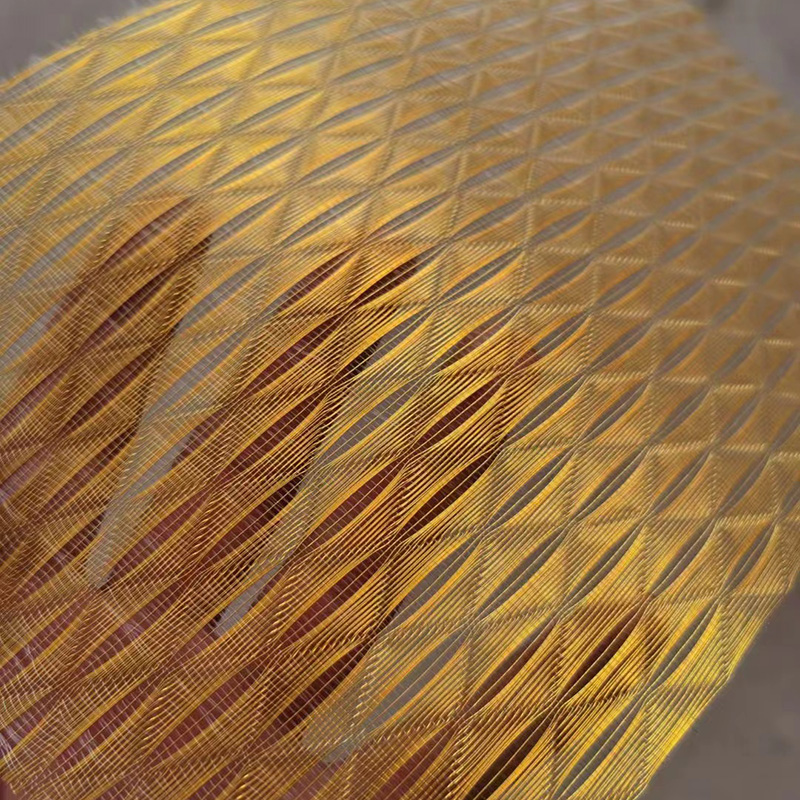

pvc coated welded mesh factory

The Manufacturing Process

The production of PVC coated welded mesh involves several stages, each critical to ensuring high-quality output. The process begins with sourcing high-grade steel wire, which is then cut to the required lengths. These wires are arranged in a grid pattern and welded at intersection points to form the base mesh.

Following the welding process, the mesh is subjected to surface preparation, which may include cleaning to remove any contaminants. The next step is the application of the PVC coating. This is typically done through either a dipping or spraying method, ensuring an even layer is applied to all surfaces. After coating, the mesh is cured in an oven, allowing the PVC to bond securely to the steel.

Finally, the finished product undergoes quality control checks to ensure it meets industry standards before being packaged for distribution. Factories specializing in PVC coated welded mesh invest in state-of-the-art machinery and technology to streamline this process, resulting in both efficiency and product consistency.

The Role of Factories

Factories that focus on the production of PVC coated welded mesh play a vital role in the supply chain. They not only provide quality products but also contribute to innovations in materials and manufacturing techniques. By leveraging advancements in technology, these factories can enhance the durability, aesthetic appeal, and cost-effectiveness of their offerings.

Moreover, as the demand for eco-friendly products rises, many manufacturers are exploring sustainable practices and materials in their production processes. This shift not only meets consumer expectations but also supports environmental conservation efforts.

Conclusion

PVC coated welded mesh is an exemplary solution in the realm of fencing and security. With its numerous advantages, including corrosion resistance, durability, aesthetic appeal, and low maintenance, it has become a go-to choice across various industries. As factories continue to refine their manufacturing processes and invest in new technologies, we can expect further enhancements to this remarkable product, making it even more beneficial for consumers looking for reliable and attractive fencing solutions.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025