-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 17, 2024 14:44 Back to list

pvc welded wire mesh manufacturer

Understanding PVC Welded Wire Mesh Insights from Manufacturers

PVC welded wire mesh is a popular choice across various industries due to its durability, flexibility, and corrosion resistance. It is a type of wire mesh that has been coated with polyvinyl chloride (PVC) to enhance its properties, making it suitable for a wide range of applications, from fencing to industrial uses. In this article, we will delve into the production, advantages, and applications of PVC welded wire mesh, shedding light on the manufacturers that contribute to this thriving market.

What is PVC Welded Wire Mesh?

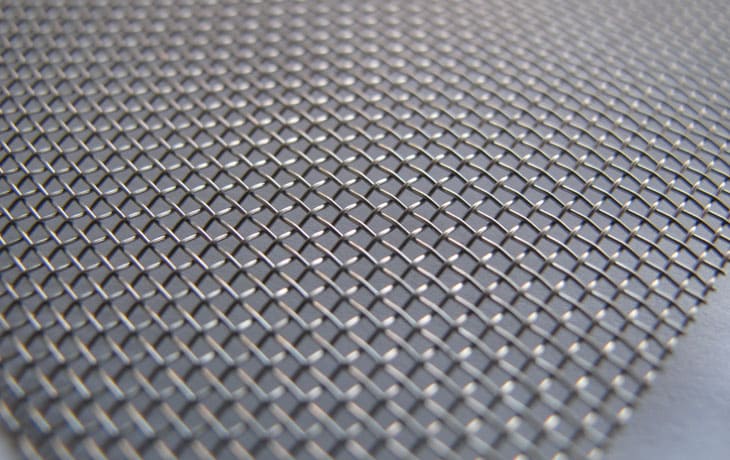

PVC welded wire mesh is made by welding together wires at their intersections, creating a grid-like structure. Once the mesh is completed, it undergoes a coating process where it is dipped or sprayed with PVC. This additional layer serves multiple purposes it improves the mesh's resistance to rust and corrosion, adds visual appeal, and increases the lifespan of the product. The wire mesh can come in various gauges and designs, catering to different needs based on strength and flexibility.

The Manufacturing Process

The manufacturing process of PVC welded wire mesh begins with the selection of high-quality steel wires. These wires are then cut to specific lengths and shaped into a grid design, where the intersections are welded using electric resistance welding techniques. Once the mesh is formed, it is prepared for coating. The PVC coating process can vary, but it typically involves either a dip coating or an extrusion method.

Dip coating involves submerging the welded wire mesh in a liquid form of PVC, allowing it to adhere uniformly to the surface. After application, the mesh is cured using high temperatures, which enables the PVC to bond effectively to the metal surface. On the other hand, extrusion processes involve melting PVC pellets and forcing them through a die to cover the mesh uniformly.

The final step involves cutting and packaging the finished products based on customer requirements. Manufacturers often emphasize quality control at every stage to ensure that the end product meets industry standards and customer specifications.

Advantages of PVC Welded Wire Mesh

1. Corrosion Resistance The PVC coating provides excellent protection against rust and corrosion, making it ideal for outdoor and industrial applications exposed to moisture.

pvc welded wire mesh manufacturer

3. Versatility PVC welded wire mesh can be designed in various sizes and colors, making it suitable for multiple applications such as fencing, animal enclosures, and garden protection.

4. Aesthetic Appeal Available in a variety of colors, it can enhance the visual aspect of a project while still providing security and functionality.

5. Easy Installation The lightweight nature of PVC welded wire mesh allows for easy handling and installation, reducing labor costs.

Applications of PVC Welded Wire Mesh

The applications of PVC welded wire mesh are vast and diverse. Some common uses include

- Fencing Solutions It serves as a reliable barricade for residential, commercial, and industrial properties, providing security without blocking visibility. - Animal Enclosures PVC welded mesh is widely used in farms and zoos for housing animals safely while allowing fresh air and light to penetrate.

- Garden and Landscape Projects It can be applied to create protective barriers around gardens, flower beds, and trees, preventing wildlife from causing damage.

- Temporary and Permanent Structures Many manufacturers provide solutions for both temporary fencing needs for events and permanent installations like swimming pools and construction sites.

- Industrial and Commercial Uses Various industries utilize PVC welded wire mesh for shelving, partitions, and safety barriers, taking advantage of its strength and durability.

Conclusion

PVC welded wire mesh represents a significant advancement in mesh manufacturing, combining strength, aesthetics, and corrosion resistance. Manufacturers play a crucial role in this industry by ensuring high-quality production processes, contributing to the mesh's overall performance. As industries continue to evolve, the demand for PVC welded wire mesh is likely to grow, providing even more innovative solutions for various applications. Whether for security, safety, or aesthetic enhancement, PVC welded wire mesh stands out as a versatile and effective choice.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025