-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 19, 2024 07:10 Back to list

Suppliers of Small Hole Perforated Metal Sheets for Various Applications

Small Hole Perforated Metal Suppliers Meeting Industrial Needs

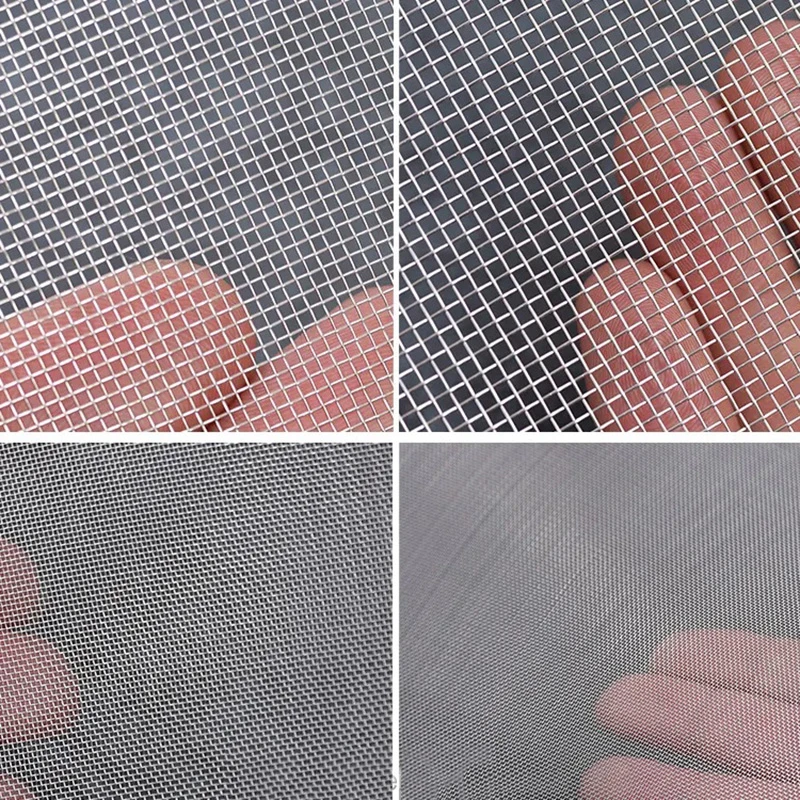

Perforated metal is a versatile material used across various industries, characterized by its unique patterns of holes. Among the many varieties, small hole perforated metal offers distinct advantages, especially in applications requiring precision and efficiency. Suppliers of this specialized material play a crucial role in delivering high-quality products that cater to specific industrial demands.

Why Choose Small Hole Perforated Metal?

Small hole perforated metal is favored in sectors such as architecture, filtration, and automotive manufacturing due to its numerous benefits. The tiny holes provide excellent ventilation while maintaining structural integrity. This makes it ideal for acoustic panels and facades, where sound absorption and light filtration are necessary. Additionally, in filtration applications, small holes enable the effective separation of solids from liquids or gases, which is essential for water treatment facilities and chemical processing plants.

The Role of Suppliers

The demand for small hole perforated metal is growing, leading to an increase in suppliers specializing in this product. These suppliers are essential as they provide a range of services, including custom fabrications, standard sizes, and diverse materials such as stainless steel, aluminum, and carbon steel. Renowned suppliers often have advanced machinery that allows for precise perforation patterns, ensuring that the final product meets stringent quality standards.

small hole perforated metal suppliers

Suppliers also play a vital role in educating customers about the capabilities of small hole perforated metal. They offer insights into the best materials and hole designs suited for specific applications. For instance, a supplier can recommend certain alloys for corrosion resistance in harsh environments or guide clients on how different hole sizes impact airflow and filtration rates.

Quality and Sustainability

A reputable supplier prioritizes quality assurance in their manufacturing processes. They often adhere to stringent industry standards and employ rigorous testing methods to ensure durability and performance. Moreover, many suppliers are increasingly adopting sustainable practices. This includes sourcing materials from responsible manufacturers, minimizing waste during production, and providing recyclable options for end-users. In today’s eco-conscious market, sustainability is not only an ethical choice but also a factor that can influence a company’s reputation and customer loyalty.

Conclusion

As industries continue to evolve, the need for specialized materials like small hole perforated metal will undoubtedly increase. Suppliers play a pivotal role in this ecosystem, providing essential products and expertise to meet the diverse needs of clients. By choosing a reliable supplier, businesses can ensure they are utilizing high-quality materials that not only enhance their operations but also align with sustainable practices.

In conclusion, whether for architectural applications, filtration systems, or any other industrial use, small hole perforated metal suppliers are indispensable partners in achieving operational excellence and innovation. Their commitment to quality, customer service, and sustainability positions them as key players in the marketplace, ensuring that industries have access to superior materials that can drive their success.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025