-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 13, 2024 03:44 Back to list

square woven wire mesh exporters

The Global Landscape of Square Woven Wire Mesh Exporters

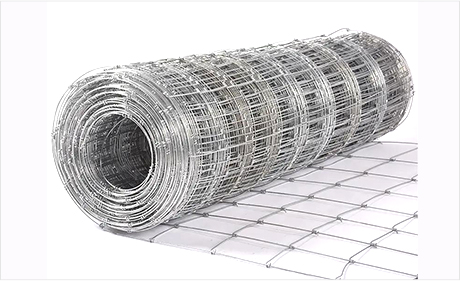

In the world of industrial materials and products, square woven wire mesh has carved out a significant niche, serving diverse applications across various sectors. This versatile material, characterized by its uniform square apertures created through the interweaving of wire strands, is used in industries ranging from construction and agriculture to filtration and safety. As the demand for durable and customizable mesh solutions grows, so does the landscape of square woven wire mesh exporters worldwide.

Understanding Square Woven Wire Mesh

Square woven wire mesh is made from various types of wire, including stainless steel, carbon steel, and galvanized wire. Its inherent properties—strength, flexibility, and corrosion resistance—make it an ideal choice for a multitude of applications. Depending on the wire gauge and mesh size, the product can be tailored to fit specific needs. For instance, it can effectively filter out particles in fluid processes, serve as safety barriers in construction sites, or provide ventilation without compromising structural integrity.

The manufacturing process of woven wire mesh involves weaving wires together to create a sturdy grid. This method allows for a high level of customization, where buyers can specify dimensions, wire types, and coating finishes to suit particular requirements. With the rise of global trade, the opportunity for exporters has expanded, allowing manufacturers to reach a broader market base.

Key Export Markets

The primary markets for square woven wire mesh include the United States, Canada, European Union nations, and emerging economies in Asia, particularly China and India. The demand in these regions is driven by growth in construction and infrastructure projects, along with increasing awareness regarding environmental sustainability, which often necessitates the use of recyclable and durable materials.

In North America, construction activities and industrial applications lead the demand for square woven wire mesh. The US construction sector has seen a resurgence since the economic downturn, resulting in an increased need for materials that can withstand harsh conditions. Similarly, in Europe, stringent regulations on safety and quality in constructions further bolster the demand for high-quality woven wire products.

Asia, particularly China and India, presents a rapidly growing market for square woven wire mesh. The region's booming construction industry, coupled with its increasing focus on manufacturing and exports, means that many local businesses are investing in durable and cost-effective materials. This creates opportunities for both local manufacturers and international exporters to cater to this expanding market.

square woven wire mesh exporters

Challenges Faced by Exporters

Despite the promising outlook, square woven wire mesh exporters face several challenges. One major hurdle is the volatility of raw material prices. Since wire mesh is typically manufactured from metals like steel, fluctuations in the global steel market can significantly impact production costs. Exporters must be agile and strategic, optimizing their pricing without compromising quality.

Moreover, compliance with varying international standards and regulations can complicate market entry for exporters. Each country may have specific requirements regarding material specifications, safety certifications, and environmental impact. Navigating these regulations requires thorough market research and often a local presence to ensure compliance and build relationships with customers.

The Role of Technology and Innovation

Modern technological advancements are reshaping the production and export of woven wire mesh. Automation and digitalization have significantly improved manufacturing efficiency, leading to increased output and reduced costs. Moreover, advancements in weaving technologies allow manufacturers to produce more complex and customized mesh designs, further enhancing product offerings.

Innovations in coating technologies are also noteworthy. For instance, advancements in galvanization and polymer coatings are enabling the production of mesh that meets rigorous corrosion resistance standards. This is particularly vital for applications exposed to harsh environments, such as marine and chemical industries.

Conclusion

The landscape of square woven wire mesh exporters is dynamic and filled with opportunities. As global industries continue to evolve, the demand for reliable and adaptable wire mesh products will likely grow. By leveraging technological advancements, maintaining quality standards, and fostering strong international relationships, exporters can capitalize on this growing market. The future for square woven wire mesh appears bright, with potential for innovation and expansion that could redefine its role across various sectors. In this ever-competitive industry, those who can adapt to changing demands and challenges will thrive, ensuring a promising future for the woven wire mesh exporting business.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025