-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 10, 2024 22:03 Back to list

Durable Stainless Steel Crimped Wire Mesh for Various Industrial Applications

The Versatility and Benefits of Stainless Steel Crimped Wire Mesh

Stainless steel crimped wire mesh is a highly versatile material that finds application in various industries due to its durability, strength, and resistance to corrosion. This wire mesh is composed of stainless steel wires that are crimped before weaving, creating a rigid structure with a range of use cases. Whether in industrial, architectural, or domestic settings, stainless steel crimped wire mesh offers numerous advantages that make it a preferred choice for many applications.

What is Crimped Wire Mesh?

Crimped wire mesh is created by passing the stainless steel wire through a crimping machine that bends the wire at regular intervals. These bends help to lock the wires together during the weaving process, resulting in a more robust and stable mesh structure. The arrangement allows for various opening sizes and wire diameters, making it customizable to meet specific needs. This type of mesh is available in different grades of stainless steel, such as 304, 316, and 430, which provide varying degrees of corrosion resistance based on the environment in which they are used.

Key Benefits

1. Corrosion Resistance One of the standout features of stainless steel crimped wire mesh is its exceptional corrosion resistance. Stainless steel contains chromium, which forms a protective layer on the surface, preventing rust and degradation even in harsh environments. This characteristic makes it ideal for use in coastal areas, food processing plants, and chemical industries, where exposure to moisture and corrosive substances is a common challenge.

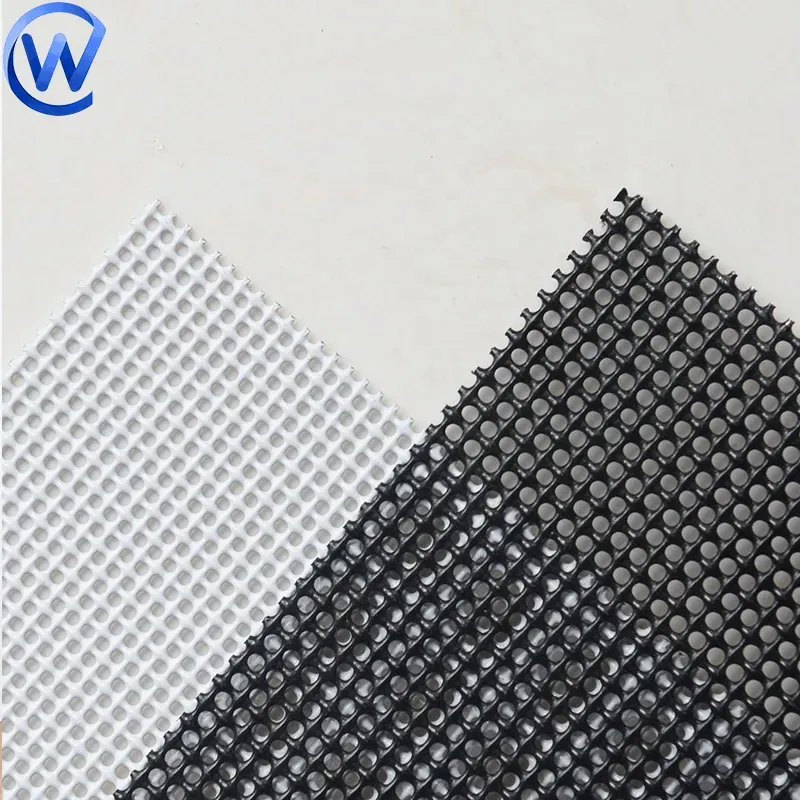

stainless steel crimped wire mesh

2. Strength and Durability The crimping process enhances the tensile strength of the wire mesh. As a result, it can withstand heavy loads and harsh conditions without deforming. This quality makes it suitable for applications such as mining, where the mesh is used for screening materials, and in construction, where it can serve as reinforcement in concrete structures.

3. Easy Maintenance Stainless steel crimped wire mesh is relatively easy to maintain. Its surface can be cleaned easily without the risk of staining or damaging the material. This property is particularly beneficial in settings like food processing plants and laboratories where hygiene is paramount.

4. Versatility The wide range of sizes and designs available makes stainless steel crimped wire mesh highly versatile. It can be used for various applications, including sieving, filtering, decorative purposes, and as a barrier. Industries such as agriculture, construction, and manufacturing have found innovative uses for crimped wire mesh, from fencing in agricultural fields to creating durable screens in construction sites.

5. Aesthetic Appeal In addition to its practical applications, crimped wire mesh can also be used in architectural designs. Its sleek appearance lends itself well to modern aesthetics, making it a popular choice for decorative facades, partitions, and railings in buildings.

Conclusion

In summary, stainless steel crimped wire mesh is an incredibly useful material boasting a combination of strength, durability, and corrosion resistance. Its customizable features allow it to adapt to various applications across different industries, making it indispensable for both functional and decorative purposes. Whether used in industrial settings, commercial structures, or residential projects, stainless steel crimped wire mesh continues to prove itself as a reliable and aesthetically pleasing solution. As industries evolve and new challenges arise, the demand for such versatile materials is likely to grow, solidifying the role of stainless steel crimped wire mesh in our everyday lives.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025