-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 12, 2024 17:07 Back to list

stainless steel crimped wire mesh factory

Understanding Stainless Steel Crimped Wire Mesh A Comprehensive Overview of the Industry

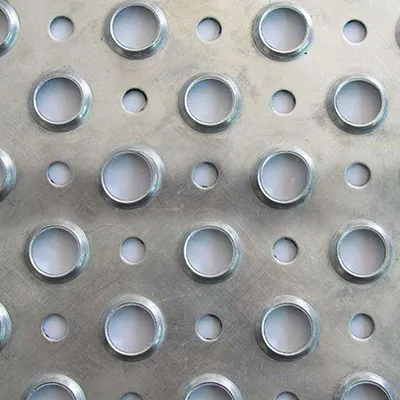

Stainless steel crimped wire mesh is an essential product in various industries due to its durability, corrosion resistance, and versatility. The process of crimping involves creating a series of waves or bends in the wire, which contributes to the mesh's structural integrity and performance. This article provides an overview of stainless steel crimped wire mesh, its applications, and the landscape of factories producing this indispensable material.

What is Stainless Steel Crimped Wire Mesh?

Stainless steel crimped wire mesh is made from high-quality stainless steel, known for its excellent resistance to rust and oxidation. The crimping process enhances its strength, allowing it to withstand significant tension and pressure. It is commonly used in environments where exposure to harsh chemicals or extreme weather conditions is prevalent, making it suitable for both industrial and commercial applications.

The Manufacturing Process

The manufacturing process of stainless steel crimped wire mesh involves several steps. First, high-grade stainless steel wires are selected. Afterward, these wires are fed into a crimping machine, where they are shaped into a series of crimped patterns. This crimping can be done in various configurations, tailored to meet specific needs. Finally, the mesh is woven together, typically using a loom, to create a strong and durable final product.

Quality control is a critical aspect of the manufacturing process. Manufacturers conduct various tests to ensure that the mesh meets industry standards. These tests assess the tensile strength, flexibility, and corrosion resistance of the wire mesh to confirm that it can perform reliably in its intended applications.

Applications of Stainless Steel Crimped Wire Mesh

Stainless steel crimped wire mesh has a broad range of applications across diverse industries. Here are some of the most prominent uses

1. Filtration and Separation In industries such as oil, gas, and pharmaceuticals, crimped wire mesh is used for filtration applications. Its precision openings allow for the efficient separation of particles and contaminants from liquids and gases.

stainless steel crimped wire mesh factory

2. Construction and Architecture The mesh is also widely used in construction projects, particularly for reinforcing concrete structures. Its strength and flexibility make it an ideal choice for various architectural designs, serving as both functional and aesthetic elements in buildings.

3. Agriculture In farming, stainless steel crimped wire mesh is employed in fencing and protecting crops from pests and animals. Its durability ensures it can withstand the rigors of outdoor environments while providing effective protection.

4. Mining and Quarrying The mining industry utilizes crimped wire mesh for sieving and sorting various materials. The robustness of the mesh ensures it can handle the heavy-duty tasks required in this sector.

5. Home and Garden Homeowners also benefit from crimped wire mesh in gardening applications, such as trellises or garden fencing, providing both decorative elements and functional barriers.

The Landscape of Crimped Wire Mesh Factories

The increased demand for stainless steel crimped wire mesh has led to the emergence of numerous factories specializing in its production. These factories focus on employing advanced technologies and reliable manufacturing practices to produce high-quality mesh that meets specific customer requirements.

Many factories also prioritize sustainability, adopting eco-friendly practices in their operations. This includes responsible sourcing of raw materials and minimizing waste during the manufacturing process. As competition grows, companies are also investing in research and development to innovate and enhance their product offerings, meeting and exceeding industry standards.

Conclusion

Stainless steel crimped wire mesh stands as a testament to the engineering capabilities of modern manufacturing. Its extensive applications in filtration, construction, agriculture, and more underscore its significance in various sectors. As factories continue to innovate and improve production processes, the future of crimped wire mesh looks promising, ensuring it remains a vital component in both industrial and everyday applications. Whether you are an industrial buyer or a DIY enthusiast, understanding the benefits and applications of stainless steel crimped wire mesh can pave the way for informed decisions in your projects.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025