-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 16, 2025 05:03 Back to list

Steel Grating

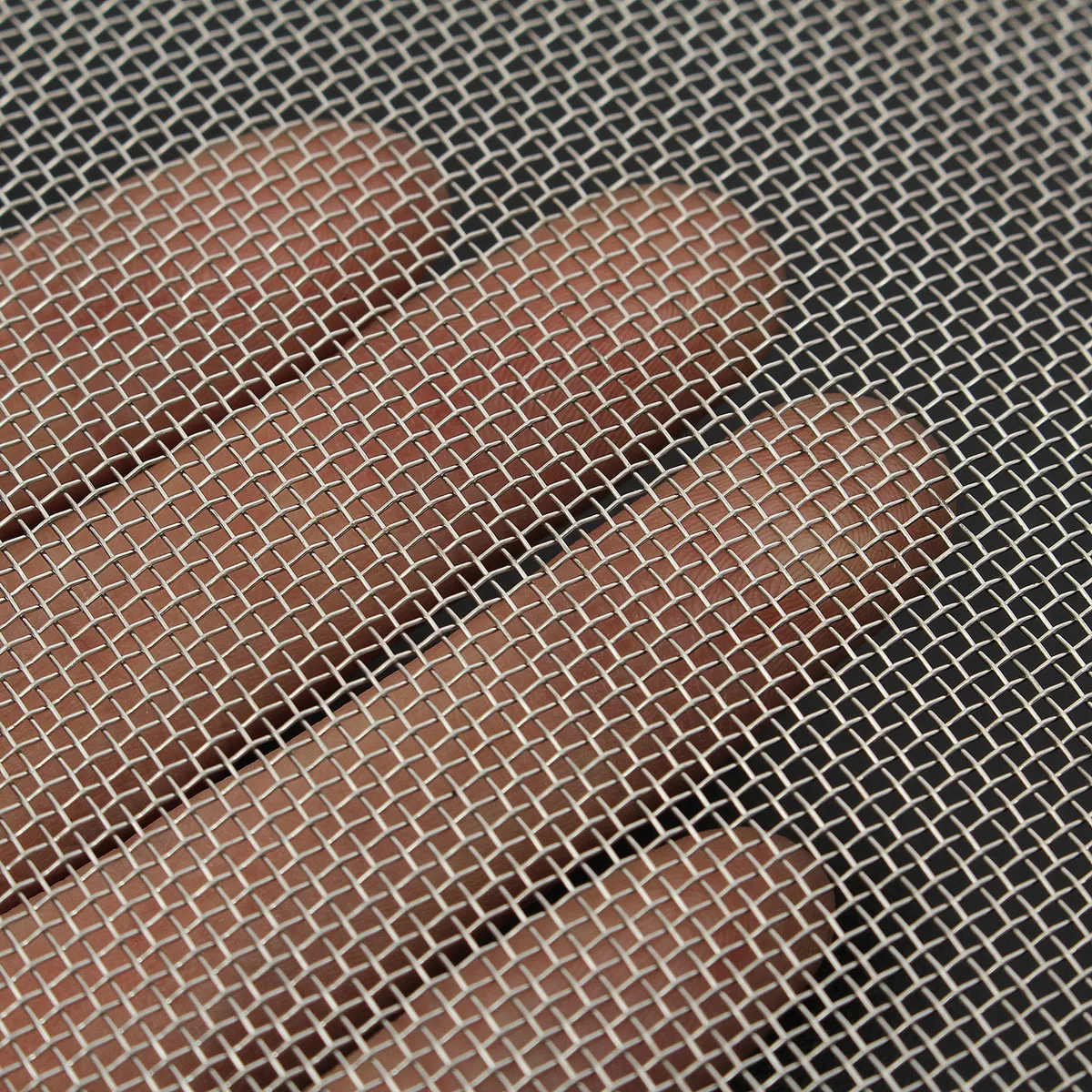

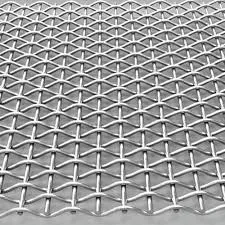

Stainless steel floor grating has emerged as a vital element in various industrial, commercial, and even residential applications. Renowned for its durability, strength, and resistance to corrosion, this material has proven its worth across numerous sectors, rapidly becoming a preferred choice for engineers and architects alike.

Trustworthiness, an essential aspect of sustainable construction and facility management, is strongly associated with stainless steel floor grating. Environmental consciousness is becoming increasingly critical in today's market, and stainless steel is a recyclable material that fits into the eco-friendly narrative. This aligns with global sustainability goals, reinforcing trust in the material's long-term viability. Moreover, its resistance to chemicals, moisture, and extreme temperatures further guarantees consistent performance across various operational conditions, thereby earning the trust of businesses and engineers focusing on robustness and longevity. Companies investing in stainless steel floor grating also benefit from the material's economic advantages. Though the initial costs might be higher than alternative materials, the return on investment becomes apparent through reduced maintenance costs, extended lifespan, and increased safety, eventually illustrating financial prudence. In summary, stainless steel floor grating, steeped in practical experience and bolstered by technical expertise, holds a revered position in modern infrastructure development. Its authoritative standing within the industry and the trust it engenders among professionals and users alike make it a compelling choice for those forefronting innovation and efficiency in facility design and maintenance. These attributes, woven together, form an undeniable argument for its adoption, driven by a desire for excellence in functionality and sustainability.

Trustworthiness, an essential aspect of sustainable construction and facility management, is strongly associated with stainless steel floor grating. Environmental consciousness is becoming increasingly critical in today's market, and stainless steel is a recyclable material that fits into the eco-friendly narrative. This aligns with global sustainability goals, reinforcing trust in the material's long-term viability. Moreover, its resistance to chemicals, moisture, and extreme temperatures further guarantees consistent performance across various operational conditions, thereby earning the trust of businesses and engineers focusing on robustness and longevity. Companies investing in stainless steel floor grating also benefit from the material's economic advantages. Though the initial costs might be higher than alternative materials, the return on investment becomes apparent through reduced maintenance costs, extended lifespan, and increased safety, eventually illustrating financial prudence. In summary, stainless steel floor grating, steeped in practical experience and bolstered by technical expertise, holds a revered position in modern infrastructure development. Its authoritative standing within the industry and the trust it engenders among professionals and users alike make it a compelling choice for those forefronting innovation and efficiency in facility design and maintenance. These attributes, woven together, form an undeniable argument for its adoption, driven by a desire for excellence in functionality and sustainability.

Next:

Latest news

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025