-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 11, 2024 07:21 Back to list

stainless steel woven wire mesh factories

Exploring the World of Stainless Steel Woven Wire Mesh Factories

In today's industrial landscape, the demand for high-quality materials is on the rise, particularly in the manufacturing and construction sectors. Among these materials, stainless steel woven wire mesh has emerged as an essential product, prized for its strength, corrosion resistance, and versatility. This article delves into the intricacies of stainless steel woven wire mesh factories, discussing their significance in various applications, manufacturing processes, and the factors that contribute to their success.

Understanding Stainless Steel Woven Wire Mesh

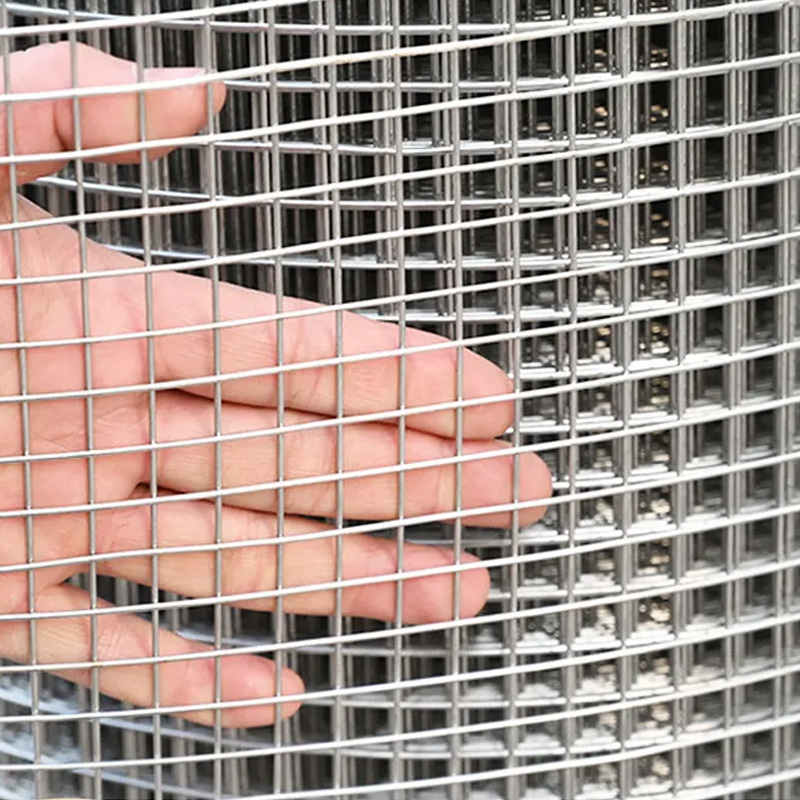

Stainless steel woven wire mesh is produced by weaving fine strands of stainless steel wire into a grid-like structure. These meshes come in various wire diameters, opening sizes, and patterns to meet different application requirements. They are widely used in industries such as aerospace, automotive, food processing, and construction due to their durability and resistance to rust and other corrosive factors.

The Role of Factories in Production

Stainless steel woven wire mesh factories are specialized facilities dedicated to the production of this essential material. The manufacturing process typically involves several key stages, including wire drawing, weaving, and finishing.

1. Wire Drawing This initial stage involves taking stainless steel billets and drawing them into finer wires. This process requires advanced machinery that can apply significant tension to create wires of precise diameters. The quality of the wire at this stage sets the foundation for the final product.

2. Weaving After the wire is prepared, it moves to the weaving section, where it is interlaced using automated looms. Different weaving patterns can be employed, such as plain weave, twill weave, or Dutch weave, depending on the intended application and required properties. Skilled operators oversee this process to ensure that the mesh is woven accurately and meets quality standards.

3. Finishing The final stage involves treatments that enhance the mesh’s properties. This may include processes such as annealing, which relieves internal stresses, or surface treatments that enhance corrosion resistance. Quality control tests are also performed to ensure the consistency and durability of the mesh.

Factors Contributing to Factory Success

stainless steel woven wire mesh factories

For stainless steel woven wire mesh factories to thrive, several factors play a pivotal role.

1. Quality Control Ensuring that products meet industry standards is crucial. Factories often implement rigorous quality control measures throughout the manufacturing process, from raw material selection to final inspections. Certifications like ISO help assure customers of product quality.

2. Innovation and Technology With advancements in technology, factories that embrace modern machinery and automated processes can enhance production efficiency and reduce costs. Innovations in weaving techniques and materials also contribute to the development of higher-quality mesh products.

3. Customer Relationships Establishing strong relationships with customers is essential for success. Factories that prioritize customer feedback and adapt their product offerings to meet specific needs can build a loyal client base.

4. Sustainability Practices As global awareness of environmental issues increases, factories that adopt sustainable practices in their operations are becoming more attractive to customers. This includes using recycled materials, reducing waste, and minimizing energy consumption.

Applications of Stainless Steel Woven Wire Mesh

The versatility of stainless steel woven wire mesh allows for diverse applications across numerous industries. In the food industry, for instance, its corrosion resistance and ease of cleaning make it indispensable for sifting, filtering, and enclosing food products. In construction, it is used for reinforcement, as well as for protective barriers and aesthetic designs in architecture. The automotive sector utilizes this mesh for filtration systems and components that require high strength and durability.

Conclusion

Stainless steel woven wire mesh factories play a critical role in meeting the increasing demand for durable and reliable materials across various industries. By focusing on quality control, innovation, customer relationships, and sustainability, these factories can not only thrive in a competitive market but also contribute to the advancement of technology and materials science. As the world continues to evolve, the importance of these factories and the products they produce will undoubtedly remain significant in shaping the future of diverse sectors.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025