-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 12, 2024 09:40 Back to list

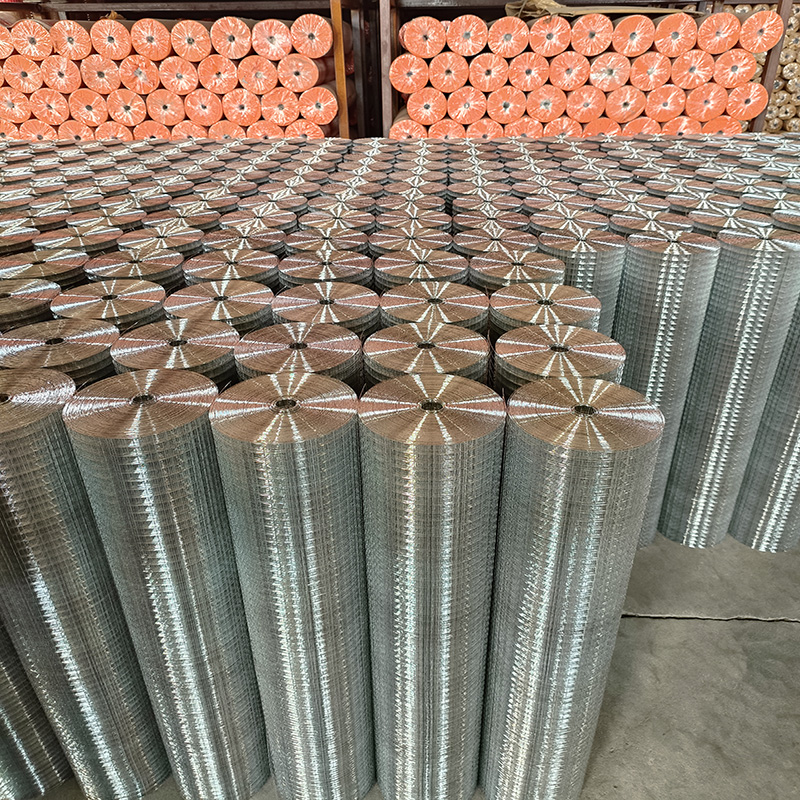

stainless steel woven wire mesh factory

The Importance of Stainless Steel Woven Wire Mesh in Modern Industry

Stainless steel woven wire mesh is a versatile material that has gained significant importance across various industries due to its unique properties and benefits. This mesh is made from stainless steel wire that is woven into a grid pattern, providing strength, durability, and resistance to corrosion. The following discussion highlights the characteristics, applications, benefits, and the manufacturing process of stainless steel woven wire mesh, emphasizing why it is indispensable in modern industrial settings.

Characteristics of Stainless Steel Woven Wire Mesh

Stainless steel is renowned for its resistance to rust and corrosion, making it an ideal choice for woven wire mesh. The use of stainless steel provides several other advantageous properties such as high tensile strength, good ductility, and excellent durability. The weaving process creates a structure that allows for flexibility, making it suitable for various applications. The wire diameter and mesh opening can be customized to meet specific requirements, allowing for a wide range of uses in different sectors.

Applications in Various Industries

Stainless steel woven wire mesh is utilized in a multitude of industries.

1. Construction and Architecture In these sectors, mesh is often used for reinforcement purposes, providing additional strength to concrete structures. Stainless steel mesh is also employed in facades to create aesthetically pleasing designs while offering protection and durability.

2. Mining and Quarrying The mining industry utilizes this mesh for filtering and separation processes. Its durability allows it to withstand harsh environments while efficiently sifting through materials.

3. Food and Beverage Food processing often requires strict hygiene standards, and stainless steel woven wire mesh is perfect for this purpose. It can be used in sieves and filters, ensuring that food safety regulations are met by preventing contamination.

4. Pharmaceuticals In the pharmaceutical sector, the mesh is used for filtration and separation in various processes. Its ability to resist chemical corrosion makes it an ideal choice for applications involving reactive substances.

5. Automotive and Aerospace These high-tech industries employ stainless steel mesh in applications such as exhaust systems and as filters. The strength and heat resistance of stainless steel make it suitable for high-performance vehicles.

stainless steel woven wire mesh factory

Advantages of Using Stainless Steel Woven Wire Mesh

The material offers numerous advantages, which include

- Corrosion Resistance The stainless steel composition ensures longevity and reliability, even in corrosive environments. - Strength and Durability The woven structure adds toughness, making it resistant to mechanical stress and impact. - Versatility Due to its customizable nature, stainless steel woven wire mesh can be tailored for various applications, making it a favorite material among engineers and architects. - Hygienic Properties Stainless steel is easy to clean and maintain, making it a suitable option for industries that prioritize hygiene, such as food and pharmaceuticals.

The Manufacturing Process

The production of stainless steel woven wire mesh typically involves several steps

1. Wire Drawing Stainless steel wire is drawn through dies to achieve the desired diameter and tensile strength. The quality of the wire is paramount, as it lays the foundation for the mesh's performance.

2. Weaving The drawn wire undergoes a weaving process, where it is interlaced to form a mesh pattern. Different weaving techniques, such as plain weave, twill weave, and Dutch weave, can be employed depending on the intended application.

3. Finishing The woven mesh may go through a finishing process that includes cutting, trimming, and sometimes coating to enhance its properties.

4. Quality Control Finally, rigorous testing and inspection are conducted to ensure that the mesh meets industry standards for strength, durability, and corrosion resistance.

Conclusion

In conclusion, the role of stainless steel woven wire mesh in modern industry cannot be overstated. Its unique properties make it suitable for a diverse array of applications across various sectors. As technology advances and industries continue to evolve, the demand for reliable and versatile materials like stainless steel woven wire mesh will only increase, solidifying its status as a cornerstone in the manufacturing and engineering domains.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025