-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jun . 12, 2024 06:23 Back to list

Steel grating factory produces storm drain covers with mesh

The Pivotal Role of Steel Grating Factories in Manufacturing Storm Drain Covers

In the realm of infrastructure and urban planning, storm drain covers play a critical role in ensuring public safety and efficient water management. These essential components are primarily fabricated from steel grating mesh, a durable and robust material that stands the test of time and harsh weather conditions. This article delves into the significance of steel grating factories in the production of storm drain covers.

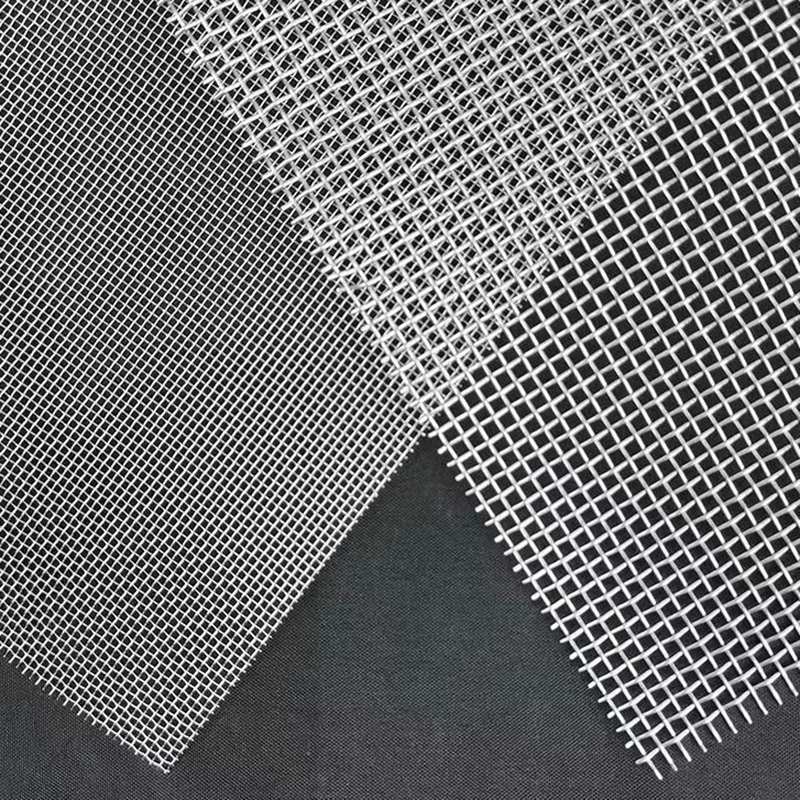

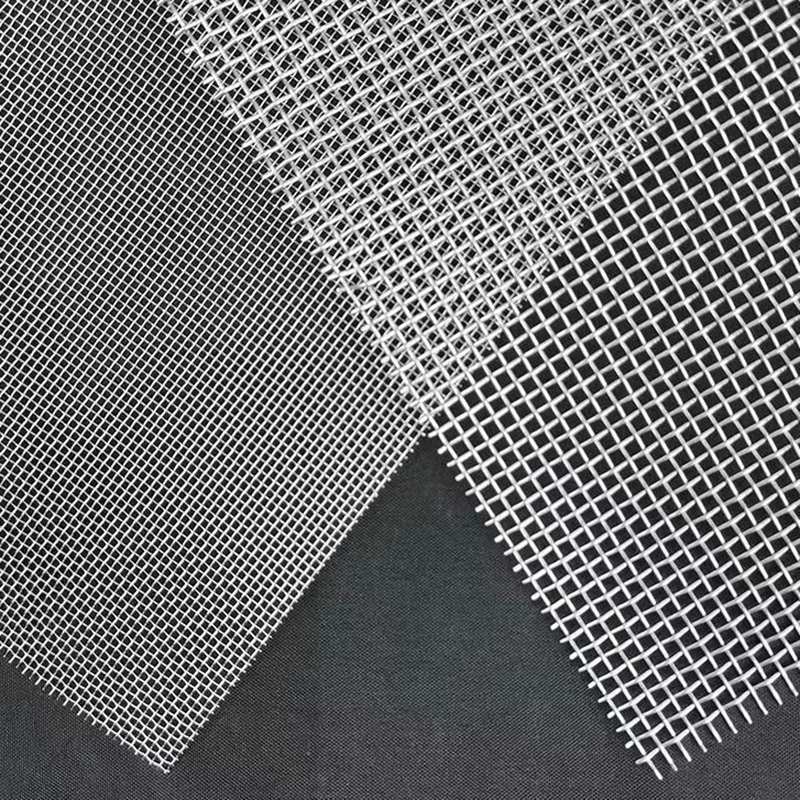

Steel grating, a lattice-like structure composed of parallel load-bearing bars and cross bars, is a staple in numerous industrial applications due to its strength, resilience, and corrosion resistance. In the context of storm drain covers, it serves as a protective barrier, preventing debris and unauthorized access while allowing water to flow freely. Steel grating factories specialize in manufacturing these crucial elements, employing advanced technology and skilled craftsmanship to ensure quality and consistency.

These specialized factories typically begin with high-grade steel, which undergoes a series of processes including cutting, welding, and galvanizing. Cutting is done to shape the steel into the desired pattern, often customized for specific drain sizes and requirements. Welding ensures the stability and durability of the grating, making it sturdy enough to withstand heavy loads and environmental pressures. The galvanizing process, where the steel is coated with a layer of zinc, provides an extra layer of protection against rust and corrosion, crucial for outdoor installations like storm drains.

The mesh design of steel grating is not only functional but also aesthetically pleasing

The mesh design of steel grating is not only functional but also aesthetically pleasingstorm drain cover steel grating mesh factory. It allows for easy visual inspection of the drain, facilitating maintenance and cleaning . Moreover, its open structure enables swift water drainage during rain events, preventing flooding and waterlogging in urban areas.

Steel grating factories also adhere to strict safety standards and engineering guidelines to guarantee the structural integrity of their products. They often conduct rigorous testing, such as load-bearing tests and corrosion resistance tests, to ensure the covers can support heavyweights and withstand harsh weather conditions. This commitment to quality control ensures that the storm drain covers they produce are reliable and safe for public use.

In addition to production, these factories also offer customization services. From different mesh sizes to various load-bearing capacities, they cater to diverse project needs, be it for residential areas, commercial complexes, or large-scale infrastructure developments.

In conclusion, the role of steel grating factories in manufacturing storm drain covers is paramount. Their expertise in steel processing, adherence to safety norms, and capacity for customization make them indispensable partners in building resilient and sustainable urban landscapes. As cities continue to grow and face increasing challenges in water management, the importance of high-quality steel grating mesh for storm drain covers, crafted by dedicated factories, will only escalate.

. Moreover, its open structure enables swift water drainage during rain events, preventing flooding and waterlogging in urban areas.

Steel grating factories also adhere to strict safety standards and engineering guidelines to guarantee the structural integrity of their products. They often conduct rigorous testing, such as load-bearing tests and corrosion resistance tests, to ensure the covers can support heavyweights and withstand harsh weather conditions. This commitment to quality control ensures that the storm drain covers they produce are reliable and safe for public use.

In addition to production, these factories also offer customization services. From different mesh sizes to various load-bearing capacities, they cater to diverse project needs, be it for residential areas, commercial complexes, or large-scale infrastructure developments.

In conclusion, the role of steel grating factories in manufacturing storm drain covers is paramount. Their expertise in steel processing, adherence to safety norms, and capacity for customization make them indispensable partners in building resilient and sustainable urban landscapes. As cities continue to grow and face increasing challenges in water management, the importance of high-quality steel grating mesh for storm drain covers, crafted by dedicated factories, will only escalate.

. Moreover, its open structure enables swift water drainage during rain events, preventing flooding and waterlogging in urban areas.

Steel grating factories also adhere to strict safety standards and engineering guidelines to guarantee the structural integrity of their products. They often conduct rigorous testing, such as load-bearing tests and corrosion resistance tests, to ensure the covers can support heavyweights and withstand harsh weather conditions. This commitment to quality control ensures that the storm drain covers they produce are reliable and safe for public use.

In addition to production, these factories also offer customization services. From different mesh sizes to various load-bearing capacities, they cater to diverse project needs, be it for residential areas, commercial complexes, or large-scale infrastructure developments.

In conclusion, the role of steel grating factories in manufacturing storm drain covers is paramount. Their expertise in steel processing, adherence to safety norms, and capacity for customization make them indispensable partners in building resilient and sustainable urban landscapes. As cities continue to grow and face increasing challenges in water management, the importance of high-quality steel grating mesh for storm drain covers, crafted by dedicated factories, will only escalate.

. Moreover, its open structure enables swift water drainage during rain events, preventing flooding and waterlogging in urban areas.

Steel grating factories also adhere to strict safety standards and engineering guidelines to guarantee the structural integrity of their products. They often conduct rigorous testing, such as load-bearing tests and corrosion resistance tests, to ensure the covers can support heavyweights and withstand harsh weather conditions. This commitment to quality control ensures that the storm drain covers they produce are reliable and safe for public use.

In addition to production, these factories also offer customization services. From different mesh sizes to various load-bearing capacities, they cater to diverse project needs, be it for residential areas, commercial complexes, or large-scale infrastructure developments.

In conclusion, the role of steel grating factories in manufacturing storm drain covers is paramount. Their expertise in steel processing, adherence to safety norms, and capacity for customization make them indispensable partners in building resilient and sustainable urban landscapes. As cities continue to grow and face increasing challenges in water management, the importance of high-quality steel grating mesh for storm drain covers, crafted by dedicated factories, will only escalate. Next:

Latest news

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025