-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 28, 2024 16:04 Back to list

Cost-effective Steel Grating Solutions from Leading Manufacturers for Your Project Needs

Understanding Steel Grating Prices from Manufacturers

Steel gratings are essential components in various industrial applications, offering robust support and safety for flooring, walkways, platforms, and more. As the demand for these products continues to grow, so does the interest in understanding their pricing structure. This article delves into the factors influencing steel grating prices from manufacturers and provides insights into what buyers can expect in terms of costs.

Types of Steel Gratings

Before discussing prices, it's important to understand that different types of steel gratings exist, each tailored for specific applications. Common options include

1. Bar Gratings Typically made from carbon steel, these gratings are composed of a series of parallel bars that provide excellent load-bearing capabilities. 2. Expanded Metal Gratings Created by cutting and stretching metal sheets, expanded metal gratings offer a lightweight solution with good airflow. 3. Welded Gratings These are manufactured by welding together flat bars and cross bars to form a durable, rigid structure suitable for heavy loads. 4. Molded Gratings Made from fiberglass, these offer a non-corrosive alternative for specific environments, although their pricing often differs from traditional steel options.

Each type serves a unique purpose, affecting its market price.

Factors Influencing Steel Grating Prices

Several factors contribute to the pricing of steel grating from manufacturers

1. Material Costs The price of raw materials, specifically steel, plays a significant role in determining the final cost. Market fluctuations, caused by global demand, tariffs, and trade policies, can lead to volatile pricing.

2. Manufacturing Processes The complexity of the manufacturing process can greatly impact costs. For example, welded gratings typically require more labor and machinery compared to simpler bar gratings, thus affecting their price.

3. Size and Thickness Larger and thicker steel gratings generally command higher prices due to the increased amount of material used and the additional fabrication required.

4. Load-Bearing Capacity Gratings designed to withstand higher loads or specific safety standards are often priced higher. The engineering and testing processes involved in certification can drive up costs.

5. Surface Treatments Galvanization, coating, and other surface treatments improve durability and corrosion resistance. While these treatments add to the longevity of the product, they also increase the manufacturing cost and, consequently, the selling price.

steel grating prices manufacturer

6. Custom Orders Custom-sized gratings or specific designs that deviate from standard dimensions often incur additional costs for both the manufacturing process and the materials used.

Average Price Ranges

While the prices of steel gratings can vary widely based on the factors mentioned above, a general price range can be established

- Standard bar gratings may range from $20 to $50 per square foot, depending on the size and thickness. - Welded gratings often fall in the range of $25 to $55 per square foot. - Expanded metal gratings typically cost between $15 to $40 per square foot. - Customized or specialty gratings can significantly exceed these ranges based on the specifics of the order.

How to Get the Best Price

To secure competitive pricing on steel gratings, consider the following strategies

1. Bulk Purchases Many manufacturers offer discounts on bulk orders, so it's worth considering how larger volume purchases can save costs in the long run.

2. Comparative Shopping Obtain quotes from multiple manufacturers to ensure you are getting the best deal. Each manufacturer may have different pricing strategies based on their production capabilities and market position.

3. Negotiate Terms Don’t hesitate to negotiate terms when placing larger orders or to see if manufacturers can offer any seasonal promotions.

4. Understand Total Costs Remember to account for shipping, installation, and any additional processing costs when evaluating the total price.

Conclusion

Understanding the pricing of steel gratings involves a variety of factors from material costs to manufacturing processes. By familiarizing yourself with these elements, you can make informed purchasing choices and find the best solutions for your specific needs. As steel gratings continue to play a vital role in various applications, staying informed about pricing trends will help you navigate the market effectively.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

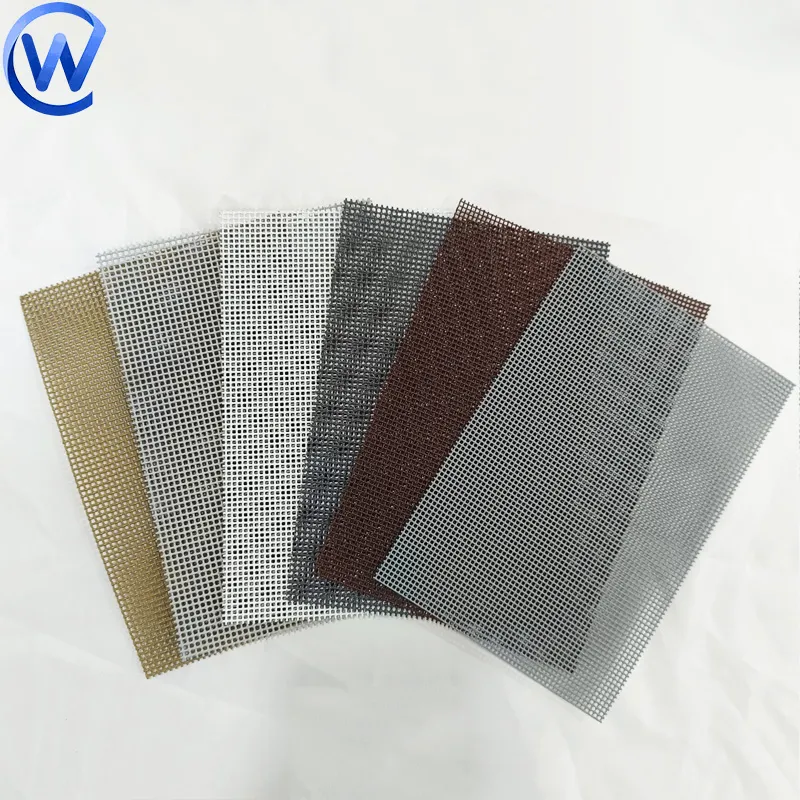

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025