-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 17, 2024 11:22 Back to list

steel grating prices manufacturers

Understanding Steel Grating Prices and Manufacturers

Steel grating is an essential product in various industries, utilized for its strength, durability, and versatility. It serves a multitude of purposes, from flooring and walkways to drainage covers and platforms in industrial settings. Given its widespread usage, it is crucial to understand the factors influencing steel grating prices and the manufacturers in the market.

Factors Affecting Steel Grating Prices

1. Material Quality The price of steel grating is directly proportional to the quality of the steel used. Higher-grade steel not only offers better strength and longevity but also comes at a higher cost. Manufacturers may use various types of steel, including mild steel, stainless steel, and other alloys. Stainless steel, for instance, is more expensive but offers superior resistance to corrosion, making it suitable for harsh environments.

2. Manufacturing Process The method used to produce steel grating also affects pricing. Common manufacturing processes include hot-dipping, welding, and press-locking. Hot-dip galvanization is a popular choice as it enhances the longevity of the product by providing a protective layer against rust. However, this additional step in the production process can increase costs.

3. Type of Grating There are various types of steel gratings, such as welded, swaged, and molded, each designed for specific applications and load requirements. The complexity of the grating type impacts the price, with welded gratings generally being more economical, while custom-made solutions can escalate costs significantly.

4. Size and Load Capacity Larger gratings or those designed to support heavier loads will typically cost more than smaller, lighter options. The size and spacing of the bars in the grating also play a role in determining the price, as denser configurations require more material and labor.

5. Surface Treatment Additional treatments such as powder coating or anodizing can also influence the final price of steel grating. While these treatments improve the aesthetic appeal and durability of the product, they add to the production costs.

6. Market Demand Like any other commodity, the price of steel grating is subject to market fluctuations. Demand in construction, infrastructure projects, and industrial applications can lead to price changes. Economic conditions, availability of raw materials, and changes in government regulations can also impact pricing.

steel grating prices manufacturers

Choosing the Right Manufacturer

When selecting a manufacturer for steel grating, it is crucial to consider several factors

1. Reputation and Experience Opt for manufacturers with a strong reputation and extensive experience in the industry. Established companies often have a proven track record of producing high-quality products and delivering them on time.

2. Customization Options Many projects require customized solutions. Look for manufacturers that offer customization options for size, design, and materials to meet your specific needs.

3. Certifications and Quality Standards Ensure that the manufacturer adheres to recognized quality standards and certifications. This is particularly important for industrial applications where safety is paramount.

4. Pricing and Value While price is an important consideration, it is equally essential to assess the overall value provided by the manufacturer. This includes product quality, customer service, and warranty options. Sometimes opting for a cheaper product can lead to higher long-term costs due to increased maintenance or replacement needs.

5. Sustainability Practices In today’s environmentally-conscious market, many buyers prefer manufacturers that practice sustainable production methods, which can include using recycled materials and minimizing waste.

Conclusion

In conclusion, understanding the various factors affecting steel grating prices and selecting the right manufacturer can significantly impact the overall quality and cost-effectiveness of your project. By considering material quality, manufacturing processes, and market dynamics, as well as the reputation and practices of manufacturers, you can ensure that you make informed decisions in your procurement process. Whether for industrial applications, construction, or utility projects, making the right choice in steel grating can lead to enhanced safety, durability, and economic efficiency.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

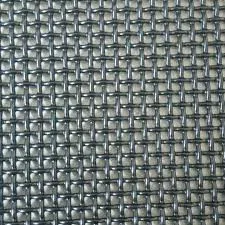

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025