-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 15, 2024 21:36 Back to list

Galvanized Welded Wire Mesh Suppliers for Durable Steel Matting Solutions

The Importance of Galvanized Welded Wire Mesh in Steel Matting

Galvanized welded wire mesh has become an essential material in various industries, proving its versatility and effectiveness in a wide range of applications. As a leading supplier of this indispensable material, it is crucial to understand its properties, advantages, and applications. This article explores the significance of galvanized welded wire mesh, highlighting its role in steel matting.

What is Galvanized Welded Wire Mesh?

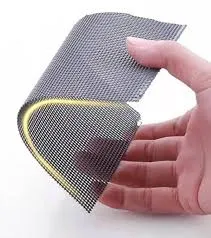

Galvanized welded wire mesh consists of steel wires that are welded together at intersections to form a strong, grid-like structure. The welding process ensures that the intersections are robust, providing improved strength compared to other forms of wire mesh. The galvanized coating offers additional protection against corrosion, extending the mesh's lifespan and making it suitable for both indoor and outdoor applications.

The coating is achieved through a process called hot-dip galvanization, where the wire is immersed in molten zinc. This creates a thick layer of zinc on the surface of the wire, which acts as a barrier to moisture and environmental elements that can lead to rust and degradation. Galvanized welded wire mesh comes in various gauges, sizes, and configurations to meet the diverse needs of different industries.

Advantages of Galvanized Welded Wire Mesh

1. Durability One of the primary benefits of galvanized welded wire mesh is its exceptional durability. The combination of steel's strength and the protective zinc coating results in a material that can withstand harsh environmental conditions. This durability makes it ideal for outdoor applications.

2. Corrosion Resistance The galvanized layer effectively protects the steel from rust and corrosion, ensuring a longer lifespan. This is particularly important in areas with high humidity or exposure to chemicals, as the mesh maintains its integrity over time.

3. Cost-Effectiveness While the initial investment in galvanized welded wire mesh may be higher than other materials, its longevity and reduced maintenance requirements make it a cost-effective solution in the long run.

4. Versatility Galvanized welded wire mesh can be used in a multitude of applications, including fencing, reinforcement in concrete and masonry, animal enclosures, and gardening. Its adaptability makes it a go-to choice for various industries.

steel matting galvanized welded wire mesh supplier

5. Ease of Installation The welded structure allows for easy handling and installation. It can be cut to size and shaped as needed, which simplifies the construction process and saves time.

Applications of Galvanized Welded Wire Mesh

Galvanized welded wire mesh finds use in multiple sectors, showcasing its versatility

- Construction In the construction industry, this mesh is often used for reinforcing concrete slabs, walls, and foundations, ensuring stability and strength. It helps distribute weight evenly and prevents cracking.

- Agriculture Farmers utilize welded wire mesh for fencing, animal enclosures, and crop protection. The sturdy construction prevents animals from escaping or intruding while offering protection to crops from pests.

- Landscaping In gardening, galvanized welded wire mesh serves as trellising for climbing plants, supporting growth while enhancing aesthetic appeal. It is also used in soil stabilization and erosion control.

- Industrial Applications Industries often use this mesh for safety barriers, shelving, and support structures. It provides a reliable solution for many operational needs.

Conclusion

As a leading supplier of galvanized welded wire mesh, understanding its significance in steel matting and various applications is crucial. Its distinctive properties, including durability, corrosion resistance, and versatility make it an invaluable material in the construction, agricultural, and industrial sectors. Investing in high-quality galvanized welded wire mesh not only ensures longevity but also enhances the safety and efficiency of projects. Whether for fencing, reinforcement, or creative landscaping solutions, this material continues to prove its worth across multiple industries.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025