-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 16, 2024 22:34 Back to list

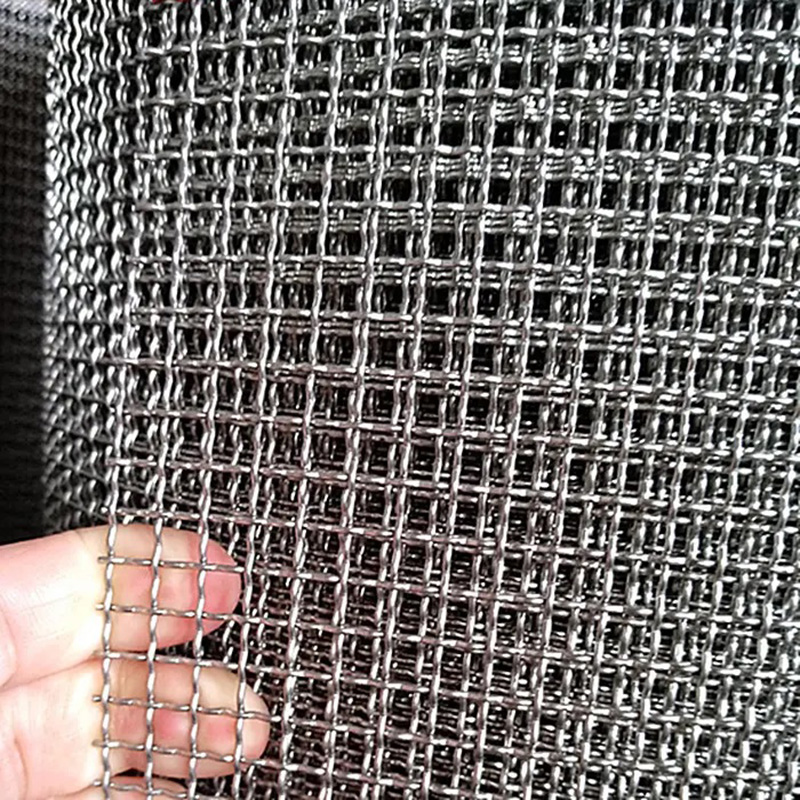

steel metal wire mesh for concrete factory

The Significance of Steel Metal Wire Mesh in Concrete Manufacturing

In the construction industry, the strength and durability of concrete structures are paramount. To enhance these properties, various materials are employed, one of the most significant being steel metal wire mesh. This innovative reinforcement solution is integral in the production of concrete products, contributing to their structural integrity and longevity.

Steel wire mesh consists of a network of steel wires arranged in a grid pattern, providing even distribution of tensile strength throughout the concrete. The primary purpose of this mesh is to prevent concrete cracking, which can compromise the overall stability and functionality of a structure. By incorporating steel wire mesh into concrete, manufacturers ensure that their products are capable of withstanding both dynamic and static loads over time.

The Significance of Steel Metal Wire Mesh in Concrete Manufacturing

Moreover, the incorporation of steel wire mesh in concrete manufacturing can lead to improved overall performance. For example, projects involving large-scale concrete pours benefit significantly from the stabilization provided by the mesh. Instead of relying solely on the inherent strength of concrete, the additional support from the wire mesh reduces the likelihood of structural failures, allowing for greater design flexibility.

steel metal wire mesh for concrete factory

In addition, steel wire mesh offers several economic advantages in concrete applications. The cost of raw materials can significantly impact construction budgets, and the utilization of wire mesh can optimize resource use. By reinforcing concrete with wire mesh, manufacturers can potentially reduce the amount of concrete needed for a project while maintaining desired strength characteristics. This reduction not only saves costs but also decreases the environmental impact of construction by using fewer resources.

The manufacturing process of steel wire mesh has also evolved significantly over the years. Modern technology has brought about advancements in production techniques, leading to the development of high-quality, durable wire mesh products. Today’s mesh is typically fabricated using high-strength steel, which provides increased performance and resistance to environmental factors such as corrosion and weathering.

Furthermore, the versatility of steel wire mesh extends to various forms and sizes, making it applicable in an array of construction projects. It can be produced in different gauges, allowing engineers and architects to choose the appropriate specifications for their designs. Whether used in precast concrete elements, roadways, or reinforced walls, the adaptability of steel wire mesh plays a crucial role in meeting diverse engineering requirements.

Safety is another critical factor in the usage of steel wire mesh in concrete manufacturing. By reinforcing concrete with steel mesh, manufacturers help ensure that structures meet stringent safety codes and regulations. This is particularly vital in areas prone to seismic activity or extreme weather conditions, where reinforced concrete structures are less likely to fail under stress. In this sense, steel wire mesh acts not only as a reinforcement material but also as a safeguard for public safety and property protection.

In summary, the integration of steel metal wire mesh in concrete manufacturing is essential for creating robust and resilient structures. This innovative reinforcement method minimizes the risk of cracking, enhances performance, and can lead to cost-effective construction solutions. As technology progresses and the demands of the construction industry evolve, the role of steel wire mesh will undoubtedly continue to be vital in producing high-quality concrete products. The future of construction lies in harnessing the advantages of such materials, ensuring safer, durable, and more efficient structures for generations to come.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025