-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 01, 2024 08:51 Back to list

Steel Wire Mesh for Concrete Applications by Leading Manufacturers in the Industry

The Importance of Steel Metal Wire Mesh in Concrete Construction

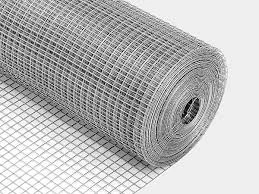

In modern construction, the incorporation of steel metal wire mesh into concrete structures has become a vital practice. This innovative material plays a crucial role in enhancing the strength, durability, and longevity of concrete, which is one of the most widely used construction materials in the world. This article explores the manufacturing process, benefits, and applications of steel wire mesh in concrete.

Manufacturing Process

The production of steel metal wire mesh typically involves high-quality steel wires that are welded together to form a grid-like structure. Manufacturers begin with high-tensile steel rods which are processed, cut, and then mechanically woven or welded into a mesh. The resulting product is available in various sizes and configurations, catering to the specific requirements of different construction projects. The rigorous quality control measures during the manufacturing process ensure that the mesh can withstand significant load and environmental stressors, making it suitable for both residential and commercial applications.

Benefits of Steel Wire Mesh in Concrete

One of the primary advantages of using steel wire mesh in concrete is its ability to distribute loads evenly across the surface. When embedded in concrete, wire mesh helps to control cracking, which is a common issue in concrete slabs due to temperature changes and settling. This increased structural integrity leads to a longer lifespan for concrete structures, thereby reducing maintenance costs over time.

Additionally, the use of wire mesh improves the tensile strength of concrete, which is naturally stronger in compression but weak in tension. By adding steel mesh, the tensile load can be effectively managed, which minimizes the risk of failure. This characteristic is especially vital in applications where concrete is exposed to dynamic loads, such as in bridges, highways, and industrial floors.

steel metal wire mesh for concrete manufacturer

Furthermore, wire mesh enhances the overall durability of concrete by reducing permeability. This means that water and harmful chemicals are less likely to penetrate the concrete, which mitigates corrosion of the embedded steel reinforcement and leads to enhanced durability in harsh environments.

Applications

Steel metal wire mesh is versatile and can be utilized in a variety of applications. It is frequently used in the construction of foundations, slabs, walls, and pavements. In residential buildings, wire mesh is often employed in basement floors and driveways to ensure stability and longevity. In commercial applications, it can be found in large industrial warehouses and multi-story parking structures, providing the necessary support for heavy loads.

Moreover, the use of wire mesh is not limited to traditional concrete. It is increasingly being utilized in poured walls, precast concrete elements, and architectural finishes, proving its adaptability and effectiveness in various construction methodologies.

Conclusion

In conclusion, steel metal wire mesh is a crucial component in contemporary concrete construction. Its manufacturing process, coupled with its remarkable benefits and diverse applications, makes it an indispensable material for builders and engineers. As the construction industry continues to evolve, the reliance on high-quality steel wire mesh will undoubtedly grow, contributing to safer, more durable, and cost-effective concrete structures for the future.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025