-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 07, 2024 09:10 Back to list

steel wire manufacturers

The Evolution and Importance of Steel Wire Manufacturers

Steel wire manufacturers play a crucial role in various industrial sectors, providing essential products that cater to a multitude of applications. The fabrication of steel wire involves a complex process that not only requires advanced technology but also a deep understanding of material properties, market demand, and sustainability practices.

The production of steel wire typically starts with the drawing of steel rods, which are then transformed into wires of various thicknesses. This drawing process ensures that the wires possess the required tensile strength and flexibility. Over the years, manufacturers have adopted innovative techniques and machinery to improve efficiency while maintaining high-quality standards. Modern steel wire manufacturing often utilizes computerized systems and automated processes, which enhance precision and reduce waste.

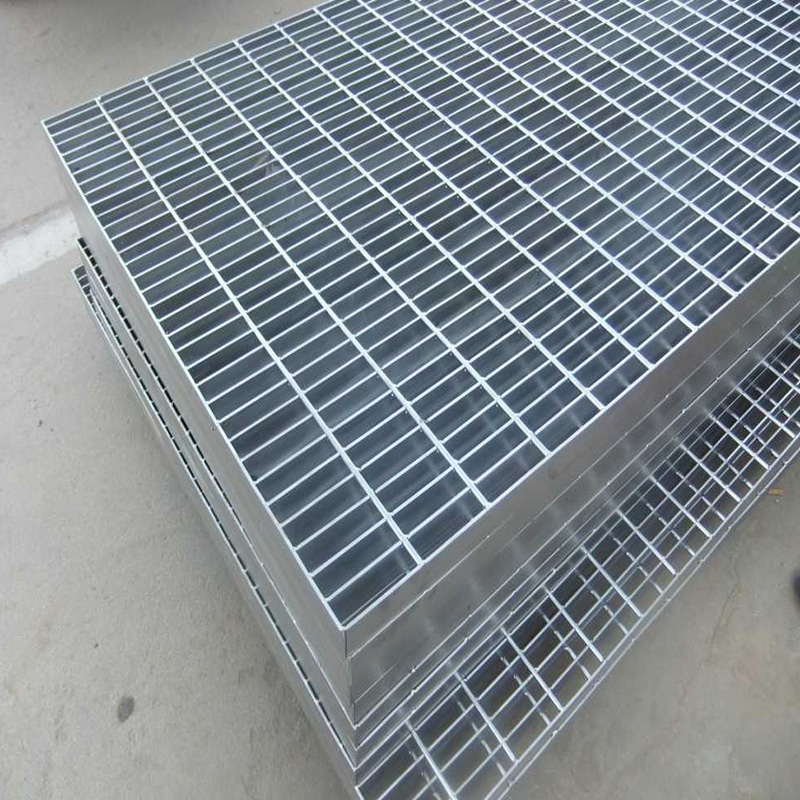

One of the main applications of steel wire is in the construction industry. Steel wire is essential for manufacturing reinforced concrete, which increases the structural integrity of buildings and infrastructures. Additionally, it is used in the production of wire mesh, barbed wire, and a plethora of other construction materials. As urbanization continues to rise globally, the demand for reliable and durable steel wire products remains high, driving manufacturers to expand their production capabilities.

Agriculture is another significant sector that benefits from steel wire products. Galvanized wire is commonly used to create fencing solutions for livestock and crops, providing a safe barrier against intruders and pests. Furthermore, steel wire is utilized in various tools and equipment that aid in farming processes, enhancing productivity and efficiency.

steel wire manufacturers

In the automotive industry, steel wire is indispensable. It is used in the production of tires, brake systems, and various components that require high strength and durability. As the automotive sector increasingly shifts towards electric vehicles, steel wire manufacturers are adapting to new requirements and technologies, ensuring they remain relevant in this evolving landscape.

Environmental sustainability is another critical aspect impacting steel wire manufacturers. The steel industry is known for its substantial carbon footprint; thus, manufacturers are actively seeking ways to reduce their environmental impact. Utilizing recycled materials, investing in energy-efficient processes, and adhering to strict environmental regulations are some of the strategies being implemented. Furthermore, innovations such as using renewable energy sources and developing new alloys with lower embodied energy are gaining traction within the industry.

The global market for steel wire continues to evolve, influenced by economic trends, technological advancements, and shifting consumer preferences. Manufacturers must remain adaptable to these changes while focusing on quality and sustainability. Collaborating with other industries and investing in research and development will be pivotal for steel wire companies aiming to stay ahead in a competitive market.

In conclusion, steel wire manufacturers are integral to a wide array of industries, ranging from construction to agriculture and automotive. As they navigate the challenges of modern production and environmental sustainability, their contributions will be vital in supporting economic growth and technological advancement. The future of steel wire manufacturing promises opportunities for innovation and development, underscoring its significance in the global economy.

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025