-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 09, 2024 20:35 Back to list

Steel Wire Mesh Manufacturing Facility Insights and Innovations for Modern Industry

The Rise of Steel Wire Mesh Factories A Comprehensive Overview

Steel wire mesh plays a crucial role in various industries, ranging from construction to agriculture, thanks to its strength, durability, and versatility. As the demand for these materials continues to grow, so does the prominence of steel wire mesh factories around the world. This article delves into the operational aspects, technological advancements, and market trends surrounding steel wire mesh production.

Understanding Steel Wire Mesh

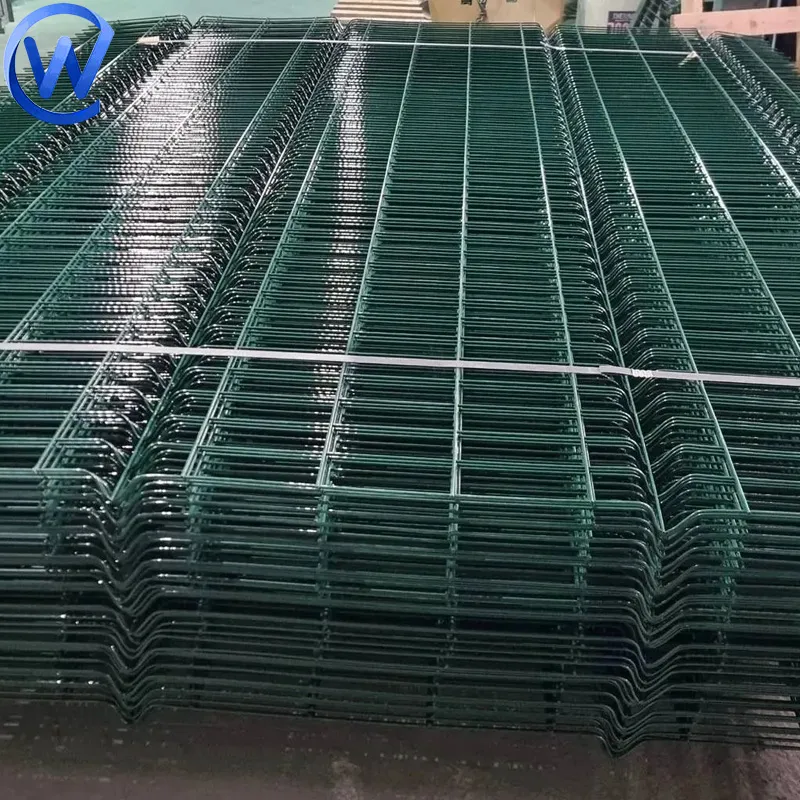

Steel wire mesh is composed of interconnected steel wires that form a grid-like structure. This mesh is used in various applications, such as concrete reinforcement, fencing, and even architectural installations. The primary appeal of steel wire mesh lies in its ability to enhance structural integrity while providing effective support in scenarios where flexibility is necessary. Moreover, it is resistant to corrosion, making it suitable for outdoor applications.

The Role of Steel Wire Mesh Factories

Steel wire mesh factories are integral to meeting the growing demand for this essential material. These factories are responsible for the production of various types of wire mesh, which can be categorized based on the wire diameter, spacing, and the material used.

Production starts with the selection of high-quality steel, which is then drawn into wires of desired thickness. These wires are then woven or welded together to create various mesh types. Automation plays a significant role in modern factories, allowing for faster production rates while maintaining quality standards.

Technological Advancements

The landscape of steel wire mesh production has evolved significantly due to technological advancements. Modern factories now employ state-of-the-art machinery and software that streamline the production process. Automated weaving and welding machines have increased accuracy and efficiency, minimizing material waste and reducing labor costs.

Furthermore, advancements in computer-aided design (CAD) technologies allow manufacturers to create customized wire mesh solutions tailored to specific client requirements. This flexibility not only enhances customer satisfaction but also enables factories to tap into niche markets.

steel wire mesh factory

In addition to manufacturing equipment, industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), are finding their way into the production process. IoT devices can monitor production lines in real-time, providing valuable data that can be analyzed to optimize workflow and prevent downtime.

Environmental Considerations

With the rising awareness of environmental issues, steel wire mesh factories are also making strides towards sustainable practices. Recycling scrap metal and implementing energy-efficient manufacturing processes are becoming commonplace. Many factories are investing in solar energy or wind power to reduce their carbon footprint, aligning with global sustainability goals.

Market Trends and Challenges

The global steel wire mesh market is experiencing steady growth, driven by increased construction activities and infrastructure development. Regions undergoing rapid urbanization, such as Asia-Pacific and parts of Africa, are leading the demand for steel wire mesh products.

However, the industry faces challenges such as fluctuating raw material costs and stringent regulations regarding environmental practices. Steel price volatility can significantly impact profit margins for manufacturers, compelling them to explore strategic sourcing and cost-effective production methods.

Additionally, competition from alternative materials, such as fiberglass and plastic mesh, poses a challenge. To remain competitive, steel wire mesh factories must continuously innovate and demonstrate the advantages of steel, such as superior durability and load-bearing capacity.

Conclusion

Steel wire mesh factories are at the forefront of producing a vital component in various industries, particularly construction. Through the integration of advanced technologies, sustainable practices, and an understanding of market trends, these factories are well-positioned to meet the demands of the future. As cities continue to grow and evolve, the relevance of steel wire mesh and its manufacturers will remain paramount in shaping modern infrastructure and architectural designs. The ongoing evolution of the steel wire mesh industry is not just a testament to engineering ingenuity but also a reflection of the ever-changing needs of society.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025