-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 16, 2024 21:30 Back to list

Top galvanized wire suppliers for durable and reliable fencing solutions near you

Understanding the Role of Galvanized Wire Suppliers

Galvanized wire, commonly used in a wide range of applications, is a staple in industries ranging from agriculture to construction. Its durability, resistance to rust and corrosion, and versatility make it an essential material for builders, manufacturers, and DIY enthusiasts alike. In this context, the role of galvanized wire suppliers becomes crucial in ensuring that high-quality products are accessible to various markets.

What is Galvanized Wire?

Galvanized wire is steel wire that has been coated with a layer of zinc to protect it from corrosion. This process not only enhances its strength but also extends its lifespan, making it an ideal choice for outdoor applications where exposure to the elements is a concern. The galvanization process can be achieved through hot-dip galvanizing or electro-galvanizing, with hot-dip offering a more robust coating.

Applications of Galvanized Wire

Galvanized wire has numerous applications. In agriculture, it is used for fencing livestock, building trellises for plants, and constructing various tools. In construction, it serves as reinforcement in concrete projects, as well as in wiring and mesh applications. Additionally, manufacturers often use galvanized wire in creating a variety of products, such as springs, hangers, and even decorative items. The adaptability of galvanized wire is one of the reasons why suppliers are in demand.

Importance of Galvanized Wire Suppliers

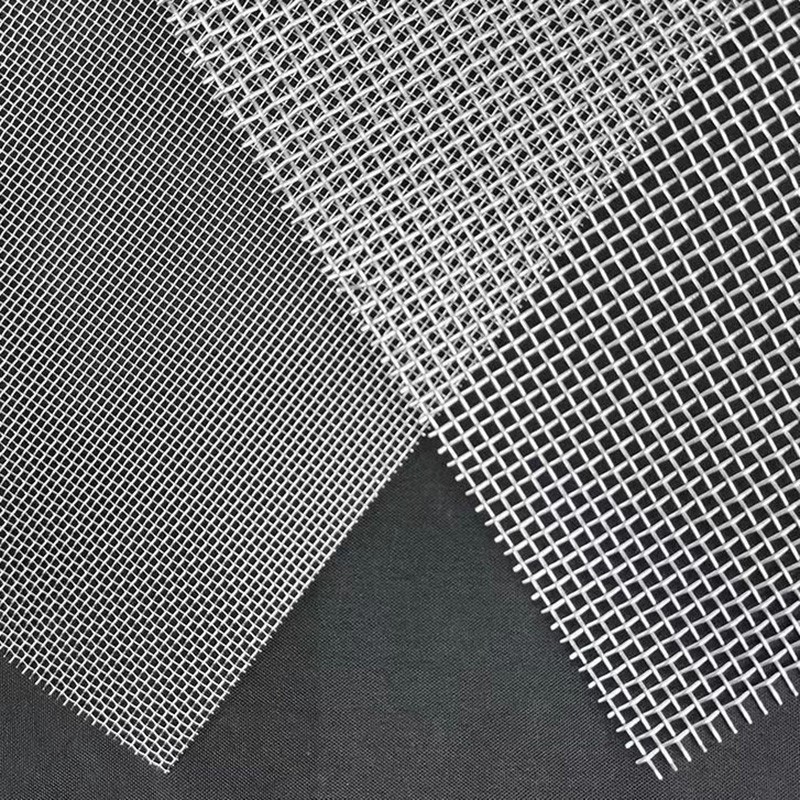

galvanized wire supplier

1. Quality Assurance Quality is paramount when it comes to materials that will be used in critical applications. Galvanized wire suppliers play a significant role in ensuring that the wire meets industry standards and regulations. They usually perform thorough inspections and tests to guarantee that the coating, tensile strength, and overall durability of the wire align with the specifications required by their clients.

2. Variety and Availability Different projects require different types of galvanized wire. Suppliers typically offer a wide range of options in terms of gauge, length, and coating types. This variety allows consumers to find the perfect fit for their specific needs without having to compromise on quality or functionality.

3. Expertise and Guidance Experienced suppliers can provide valuable expertise to their customers. They can advise on the best types of galvanized wire for specific applications, helping clients make informed decisions. This advisory role is especially critical for those who may not have extensive experience in selecting materials for construction or agricultural projects.

4. Logistical Support Efficient suppliers also handle logistics, ensuring that products are delivered on time and in good condition. This aspect is crucial, especially in construction, where project timelines often hinge on the availability of necessary materials. A reliable galvanized wire supplier can streamline the procurement process, allowing contractors and manufacturers to focus on their core activities.

5. Cost Efficiency Working with a reputable supplier can lead to cost savings. They often have access to bulk purchasing and can reduce overhead costs, passing those savings onto their customers. Moreover, by ensuring quality products, suppliers help minimize the risk of faulty materials that could lead to additional expenses down the line.

Conclusion

Galvanized wire suppliers play an indispensable role in various industries by providing crucial materials that enhance the durability and longevity of products and structures. Their commitment to quality, variety, expert guidance, logistical support, and cost efficiency make them valuable partners for builders, manufacturers, and agricultural professionals alike. As industries continue to evolve and the demand for high-quality materials grows, the reliance on reputable galvanized wire suppliers is likely to increase, ensuring a robust supply chain for essential construction and agricultural needs.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025