-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jun . 26, 2024 12:29 Back to list

Top Manufacturers of Stainless Steel Welded Wire An Exploration

The Pivotal Role of Stainless Steel Welded Wire Factories

Stainless steel welded wire factories are integral components of the global manufacturing industry, playing a significant role in producing high-quality materials for a diverse range of applications. These factories specialize in the production of stainless steel welded wire, a material renowned for its durability, corrosion resistance, and strength.

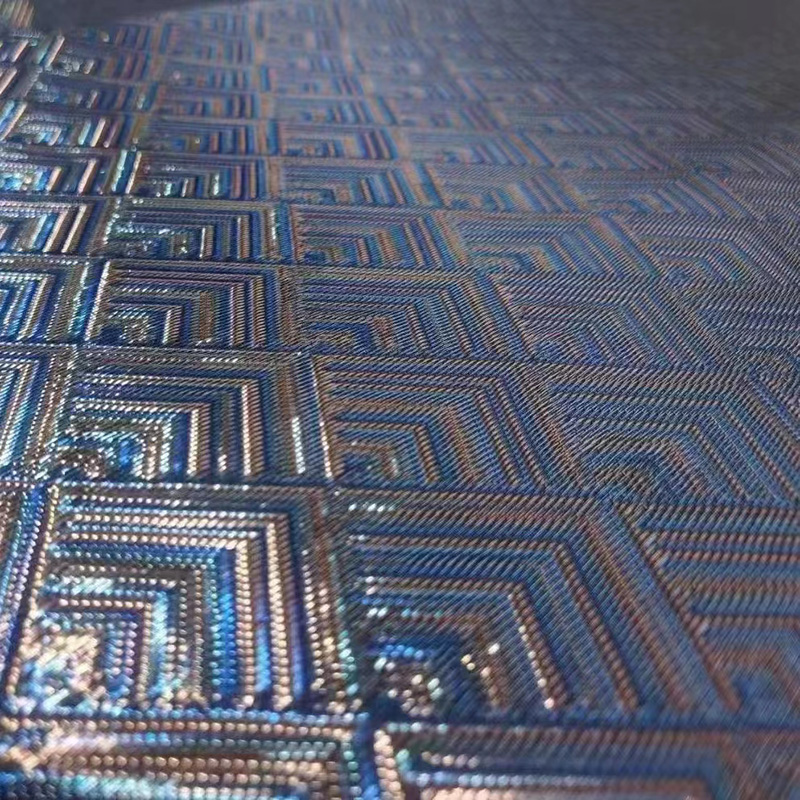

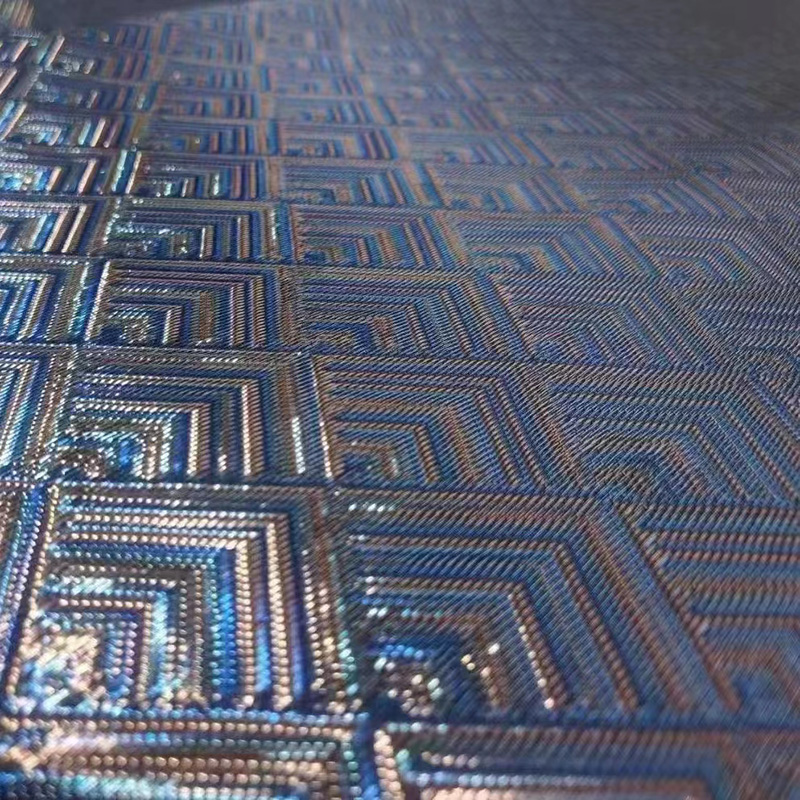

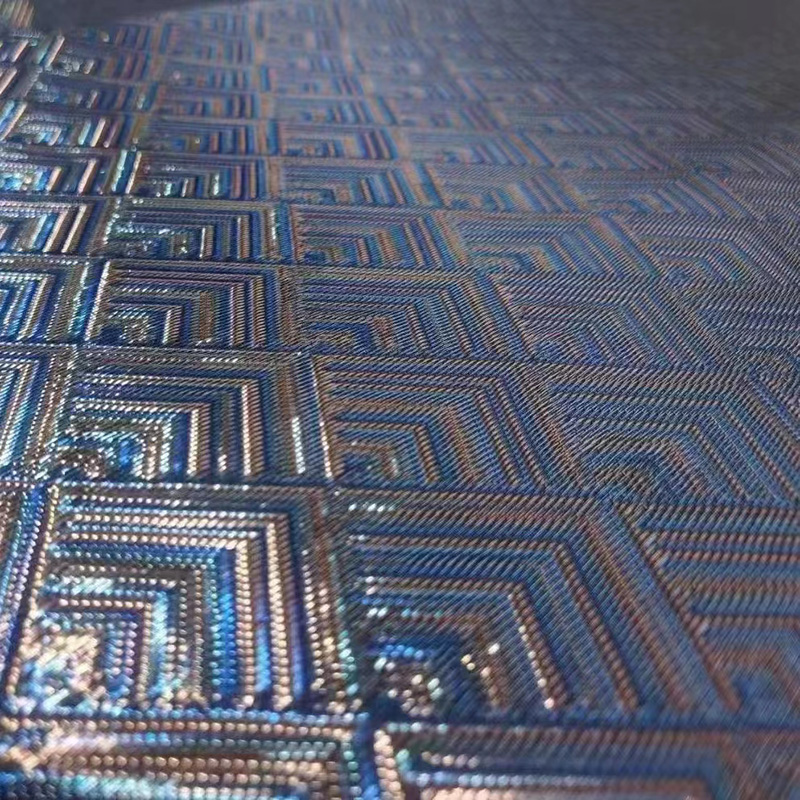

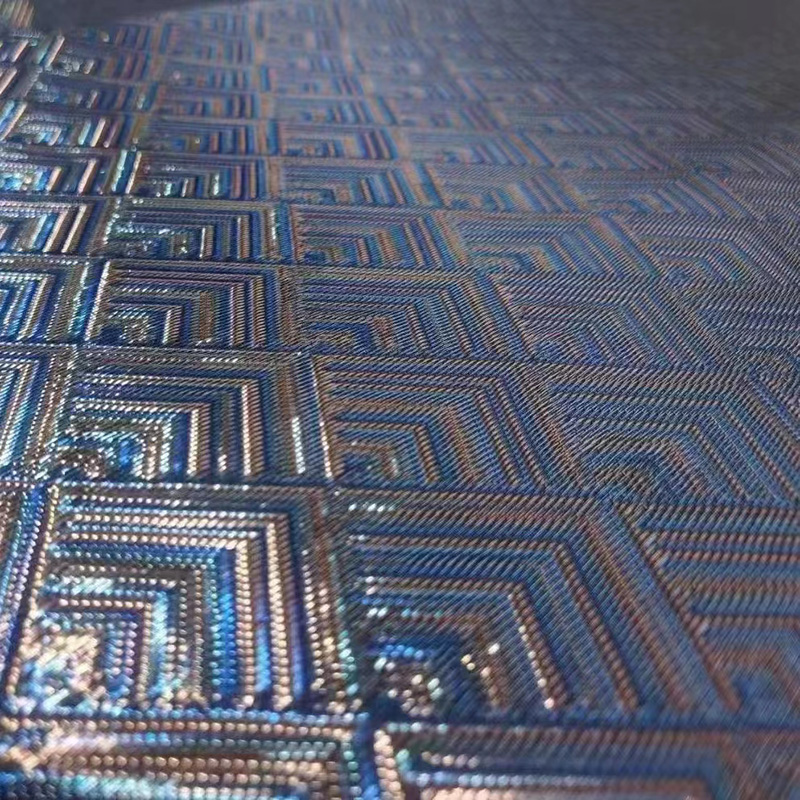

Welded wire, as the name suggests, is created by welding together individual steel wires at their intersections to form a mesh pattern. When this process is applied to stainless steel, the result is a product that combines the inherent properties of steel with the added benefits of stainless steel, such as rust resistance and aesthetic appeal. This makes it ideal for use in various sectors, including construction, agriculture, petrochemical, and even food processing.

The manufacturing process in stainless steel welded wire factories is a blend of art and science. It begins with selecting the right grade of stainless steel, which could be 304, 316, or other grades depending on the end-use requirements. The steel wires are then cut to the desired length and fed into sophisticated welding machines. These machines use electric current to fuse the wires at their intersections, creating a robust and seamless mesh.

Quality control is a critical aspect of operations in these factories. Each stage of the production process, from wire drawing to welding and final inspection, is meticulously monitored to ensure compliance with international standards Each stage of the production process, from wire drawing to welding and final inspection, is meticulously monitored to ensure compliance with international standards Each stage of the production process, from wire drawing to welding and final inspection, is meticulously monitored to ensure compliance with international standards Each stage of the production process, from wire drawing to welding and final inspection, is meticulously monitored to ensure compliance with international standards

Each stage of the production process, from wire drawing to welding and final inspection, is meticulously monitored to ensure compliance with international standards Each stage of the production process, from wire drawing to welding and final inspection, is meticulously monitored to ensure compliance with international standards stainless steel welded wire factories. Advanced testing equipment is employed to check the tensile strength, elongation, and weld integrity of the finished product.

Moreover, stainless steel welded wire factories often invest in cutting-edge technology and automation to enhance efficiency and precision. This not only boosts productivity but also reduces waste, thereby contributing to sustainable manufacturing practices. Some factories have even incorporated robotics and artificial intelligence into their processes, revolutionizing the way stainless steel welded wire is manufactured.

Furthermore, these factories are vital to local economies, providing employment opportunities and fostering industrial growth. They also contribute to the global supply chain, exporting their products worldwide to meet the ever-increasing demand for stainless steel welded wire.

In conclusion, stainless steel welded wire factories are the backbone of industries that rely on durable and corrosion-resistant materials. Their commitment to quality, technological advancement, and sustainable practices underscores their importance in today's manufacturing landscape. As the world continues to seek more resilient and eco-friendly solutions, the role of these factories is set to become even more pivotal in shaping the future of infrastructure and industrial applications.

stainless steel welded wire factories. Advanced testing equipment is employed to check the tensile strength, elongation, and weld integrity of the finished product.

Moreover, stainless steel welded wire factories often invest in cutting-edge technology and automation to enhance efficiency and precision. This not only boosts productivity but also reduces waste, thereby contributing to sustainable manufacturing practices. Some factories have even incorporated robotics and artificial intelligence into their processes, revolutionizing the way stainless steel welded wire is manufactured.

Furthermore, these factories are vital to local economies, providing employment opportunities and fostering industrial growth. They also contribute to the global supply chain, exporting their products worldwide to meet the ever-increasing demand for stainless steel welded wire.

In conclusion, stainless steel welded wire factories are the backbone of industries that rely on durable and corrosion-resistant materials. Their commitment to quality, technological advancement, and sustainable practices underscores their importance in today's manufacturing landscape. As the world continues to seek more resilient and eco-friendly solutions, the role of these factories is set to become even more pivotal in shaping the future of infrastructure and industrial applications.

Each stage of the production process, from wire drawing to welding and final inspection, is meticulously monitored to ensure compliance with international standards Each stage of the production process, from wire drawing to welding and final inspection, is meticulously monitored to ensure compliance with international standards

Each stage of the production process, from wire drawing to welding and final inspection, is meticulously monitored to ensure compliance with international standards Each stage of the production process, from wire drawing to welding and final inspection, is meticulously monitored to ensure compliance with international standards stainless steel welded wire factories. Advanced testing equipment is employed to check the tensile strength, elongation, and weld integrity of the finished product.

Moreover, stainless steel welded wire factories often invest in cutting-edge technology and automation to enhance efficiency and precision. This not only boosts productivity but also reduces waste, thereby contributing to sustainable manufacturing practices. Some factories have even incorporated robotics and artificial intelligence into their processes, revolutionizing the way stainless steel welded wire is manufactured.

Furthermore, these factories are vital to local economies, providing employment opportunities and fostering industrial growth. They also contribute to the global supply chain, exporting their products worldwide to meet the ever-increasing demand for stainless steel welded wire.

In conclusion, stainless steel welded wire factories are the backbone of industries that rely on durable and corrosion-resistant materials. Their commitment to quality, technological advancement, and sustainable practices underscores their importance in today's manufacturing landscape. As the world continues to seek more resilient and eco-friendly solutions, the role of these factories is set to become even more pivotal in shaping the future of infrastructure and industrial applications.

stainless steel welded wire factories. Advanced testing equipment is employed to check the tensile strength, elongation, and weld integrity of the finished product.

Moreover, stainless steel welded wire factories often invest in cutting-edge technology and automation to enhance efficiency and precision. This not only boosts productivity but also reduces waste, thereby contributing to sustainable manufacturing practices. Some factories have even incorporated robotics and artificial intelligence into their processes, revolutionizing the way stainless steel welded wire is manufactured.

Furthermore, these factories are vital to local economies, providing employment opportunities and fostering industrial growth. They also contribute to the global supply chain, exporting their products worldwide to meet the ever-increasing demand for stainless steel welded wire.

In conclusion, stainless steel welded wire factories are the backbone of industries that rely on durable and corrosion-resistant materials. Their commitment to quality, technological advancement, and sustainable practices underscores their importance in today's manufacturing landscape. As the world continues to seek more resilient and eco-friendly solutions, the role of these factories is set to become even more pivotal in shaping the future of infrastructure and industrial applications. Latest news

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025