-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jul . 30, 2024 17:56 Back to list

Top Quality Stainless Steel Wire Mesh Manufacturing for Various Industrial Applications

Exploring SS Wire Mesh Factory Producing Quality Stainless Steel Mesh

Stainless steel wire mesh is an essential product used across various industries, including construction, food processing, pharmaceuticals, and more. The SS wire mesh factory plays a crucial role in producing high-quality wire mesh that meets diverse consumer needs. This article delves into the operations of a stainless steel wire mesh factory, highlighting its manufacturing processes, applications, and the importance of quality standards.

Manufacturing Process

The production of stainless steel wire mesh involves several crucial steps, each ensuring the final product's quality and durability. The process typically begins with the selection of appropriate stainless steel grades, with 304 and 316 being the most common due to their excellent corrosion resistance and strength. Once the raw materials are chosen, the following steps are undertaken

1. Wire Drawing This initial stage involves reducing the diameter of stainless steel rods into fine wire. The rods are pulled through a series of dies, producing wires of various thicknesses suited for different mesh specifications.

2. Weaving After wire drawing, the drawn wires are woven together to create the mesh fabric. This weaving process can vary to produce different patterns – including plain, twill, and Dutch weave – depending on the intended application. The precision of the weaving is critical, as it directly affects the mesh’s strength and filtering capabilities.

3. Finishing Once woven, the wire mesh undergoes cleaning to remove any residues from the weaving process. This may include acid washing or galvanization, which not only clean the mesh but can also enhance its resistance to rust and corrosion.

4. Cutting and Packaging After finishing, the mesh is cut to specifications and prepared for shipping. Factory workers ensure that each roll or sheet is packaged securely, preserving its integrity during transportation.

Applications of SS Wire Mesh

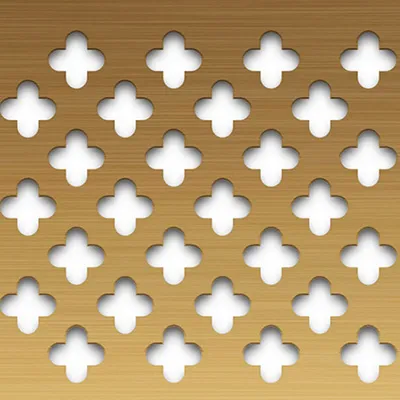

ss wire mesh factory

The versatility of stainless steel wire mesh means it is used in a wide range of applications. Some notable uses include

- Filtration SS wire mesh is widely employed in the filtration of liquids and gases in various industries. Its durability and resistance to high temperatures make it ideal for use in the food and beverage industry, water treatment plants, and chemical processing.

- Construction In construction, stainless steel mesh is used for reinforcing concrete structures, providing added strength and durability. It is also used in window screens and fencing, combining aesthetic appeal with functional benefits.

- Civils and Agriculture In agricultural settings, SS wire mesh serves as fencing and even as a support structure for climbing plants. In civil engineering, it is often used in soil stabilization and erosion control.

Importance of Quality Standards

In the production of stainless steel wire mesh, adherence to stringent quality standards is paramount. Factories often comply with international standards such as ISO and ASTM to ensure that their products meet the required specifications. Rigorous testing during the manufacturing process—including tensile strength testing, corrosion resistance, and mesh opening size verification—guarantees that the final product is reliable and safe for various applications.

Moreover, maintaining quality not only ensures customer satisfaction but also enhances the factory's reputation in a competitive market. Investing in advanced machinery and skilled technicians further underscores a factory's commitment to producing top-notch stainless steel wire mesh.

Conclusion

The SS wire mesh factory plays an integral role in producing essential materials that bolster numerous industries. Through meticulous manufacturing processes, adherence to quality standards, and a keen understanding of market demands, these factories deliver durable and versatile wire mesh solutions. As industries evolve and new applications for stainless steel wire mesh emerge, the importance of such factories will only grow, reinforcing their position as key players in the industrial landscape.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025