-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 04, 2024 23:24 Back to list

twisted soft annealed iron wire factories

Twisted Soft Annealed Iron Wire Factories An Insight into Production and Applications

Twisted soft annealed iron wire is a versatile material utilized in various industries, renowned for its flexibility, strength, and ease of use. This article explores the manufacturing processes of twisted soft annealed iron wires, the operational aspects of factories producing them, and their applications across different sectors.

Manufacturing Process

The journey of twisted soft annealed iron wire begins with quality raw materials. Factories typically procure high-grade iron or steel rods, which are carefully selected based on their chemical properties and mechanical strength. The production process involves several stages wire drawing, annealing, twisting, and packaging.

Initially, the raw rods are subjected to wire drawing, a method where the rods are pulled through progressively smaller dies to achieve the desired diameter. This process not only reduces the thickness of the wire but also enhances its tensile strength. After drawing, the wire undergoes annealing—a heat treatment process that involves heating the wire to a specific temperature and then cooling it gradually. This process softens the wire, making it more malleable and reducing internal stresses, which is crucial for applications requiring flexibility.

Once the annealing process is complete, the softened wire is twisted. Twisting involves spinning multiple strands of wire together in a helical pattern, which increases the overall strength and provides various forms of product, including twisted pair wires, which are commonly used in electrical applications to reduce electromagnetic interference.

Finally, the twisted wires are cut to specified lengths and packaged for shipment. Throughout the manufacturing process, quality control measures are essential to ensure that the final product meets industry standards and customer specifications. Factories often employ advanced testing methods to assess the tensile strength, flexibility, and corrosion resistance of the wires.

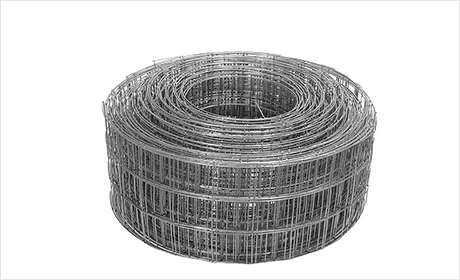

twisted soft annealed iron wire factories

Factory Operations and Efficiency

In a typical twisted soft annealed iron wire factory, efficiency and automation play significant roles. Modern factories are equipped with high-performance machinery that enables faster production rates while maintaining quality. Automated systems monitor every stage, from the initial wire drawing to the final packaging, minimizing human error and enhancing overall productivity.

Additionally, manufacturers are increasingly adopting sustainable practices. Many factories use eco-friendly processes and materials, reducing the environmental footprint associated with wire production. Through recycling scrap metal and utilizing renewable energy sources, these factories not only cut costs but also adhere to global sustainability standards.

Applications of Twisted Soft Annealed Iron Wire

The applications of twisted soft annealed iron wire are extensive and varied. In the construction industry, it is widely used for binding, fencing, and reinforcing purposes due to its excellent tensile strength. In agriculture, farmers utilize it for trellising plants, creating enclosures, and securing crops.

Moreover, this type of wire finds significant use in the manufacture of wire mesh, gabions, and other forms of containment systems. The automotive industry employs twisted soft annealed iron wires for components such as springs and cables, while the electrical sector relies on twisted pairs for reliable connection systems in telecommunications.

In conclusion, twisted soft annealed iron wire factories play a crucial role in delivering high-quality, flexible, and strong wire products that serve various industries. With ongoing advancements in technology and sustainable practices, these factories not only meet the demands of modern manufacturing but also contribute positively to environmental conservation. As the need for reliable and durable materials continues to grow, twisted soft annealed iron wire will undoubtedly remain a key player in industrial applications.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025