-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 19, 2024 17:18 Back to list

Supplier of Soft Annealed Iron Wire in Twisted Form for Various Applications

Twisted Soft Annealed Iron Wire An Essential Material in Various Industries

Twisted soft annealed iron wire is a versatile and indispensable material widely used across various industries. Produced through a meticulous process of annealing and twisting, this type of wire combines ductility and tensile strength, making it ideal for numerous applications. In this article, we will delve into the characteristics, manufacturing process, applications, and advantages of twisted soft annealed iron wire, shedding light on its significance in modern manufacturing.

Characteristics of Twisted Soft Annealed Iron Wire

Twisted soft annealed iron wire is known for its remarkable flexibility and malleability. The annealing process softens the iron, allowing it to be easily manipulated into different shapes without breaking. As a result, this wire is often used in applications where forming and bending are required. The twisting process further enhances its strength, enabling the wire to withstand tension and physical stress. Typically, this wire is available in various diameters, making it suitable for a wide range of uses, from light to heavy-duty applications.

Manufacturing Process

The production of twisted soft annealed iron wire involves several key steps. Initially, high-quality iron is drawn into wire form, which can vary in thickness based on the intended application. Subjecting the wire to an annealing process involves heating it in a controlled environment to achieve the desired softness and ductility. After annealing, the wire is twisted to create a stronger and more durable product. This twisting process not only enhances its structural integrity but also improves its overall appearance. Once twisted, the wire can undergo additional treatments such as coating or galvanization, depending on the end-use requirements.

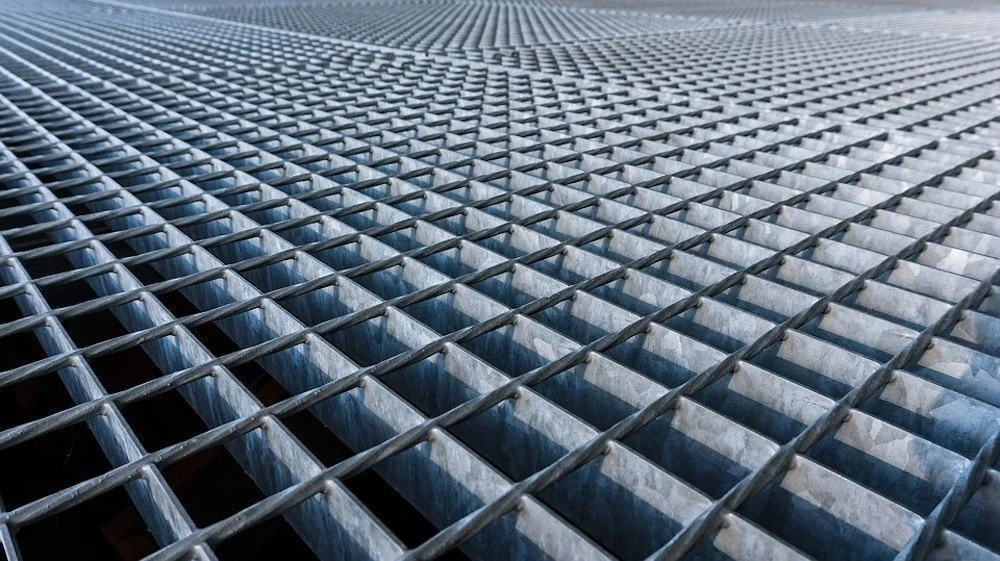

twisted soft annealed iron wire supplier

Applications

Twisted soft annealed iron wire finds applications in various sectors, including construction, agriculture, and manufacturing. In construction, it is commonly used in reinforcing concrete and fabricating wire mesh for safety and support structures. Its flexibility allows for easy manipulation during installation. In agriculture, twisted wire serves as an effective fencing solution, providing boundary and livestock containment while maintaining durability against environmental elements. Additionally, the wire is prevalent in the manufacturing of heavy-duty products, such as marine and automotive components, where strength and resilience are essential.

Advantages

The advantages of using twisted soft annealed iron wire are numerous. Firstly, its superior flexibility allows for easy handling and installation across various applications. Secondly, its resistance to breakage under tension makes it reliable for critical structural purposes. Additionally, it offers excellent corrosion resistance when properly coated, extending the lifespan of products made from this material. Furthermore, twisted soft annealed iron wire is cost-effective, making it an economical choice for large-scale projects without compromising quality.

Conclusion

In summary, twisted soft annealed iron wire is a crucial material that plays a significant role in multiple industries. Its unique combination of flexibility, strength, and durability, along with its cost-effectiveness, makes it a favored choice among manufacturers and construction professionals alike. With ongoing advancements in manufacturing processes, the demand for high-quality twisted soft annealed iron wire will continue to rise, supporting innovation and development in various sectors. Whether for construction, agriculture, or manufacturing, this wire remains an essential material that meets diverse industrial needs, showcasing its enduring relevance in the modern world.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025